There isn’t one of us who has not been affected or knows someone who has been affected by the economic crisis, downturn, recession or whatever catch phrase is being used this week in an effort to try and keep us from focusing on one reality that we all are aware of – the cupboards are bare, in the immortal words of old Mother Hubbard. We are finding that small things really are a big deal.

To many of us as individuals, this month’s topic may not seem to be a big deal, but it is certainly getting a lot of attention in the world of fleets and even the OEs. Engine coolant/anti- freeze recycling is a relatively new and emergent industry and though much of our involvement with it may seem to be on the disposal side, it can impact you personally and professionally for reasons you may not expect.

In the late ’80s, new federal government regulations labeled materials containing lead levels of more than 5.0 ppm as hazardous, a limit that most used engine coolant exceeded. Subsequently, equipment and vehicle maintenance facilities had to find methods to deal with and reduce the costs of these new hazardous wastes, and preserve the environment. This demand to reduce hazardous wastes and related costs created opportunities for many different companies and groups to develop and market effective means of recycling used engine coolants. Since ethylene and propylene glycol are economically recoverable components in engine coolants, many different ways were developed to separate out the contaminants from both chemicals.

As this young market developed and entrepreneurial opportunities presented themselves several different technologies developed, including simple filtration, ultra-filtration, chemical precipitation and filtration, reverse osmosis, ion-exchange and distillation. It soon became apparent that many recyclers were producing inexpensive and poor quality recycled engine coolants while others provided higher quality recycled engine coolants. This disparity led to understandable and significant concern from OEMs and state regulatory bodies. Without industry standards, there would be a clash between engine manufacturers and recycled coolant providers over warranties and responsibility.

Worldwide, over 400 million gallons of antifreeze concentrate are sold each year. After the typical 50% dilution with water, this yields about 800 million gallons of engine coolant. Between 25 and 50% of this volume ends up improperly in the environment, and dumping by consumers is a major cause of this pollution. Approximately 90% is mixed with wastewater, treated, then discarded to surface waters. Governments are imposing more regulations concerning antifreeze management. This means more antifreeze will be collected for beneficial reuse/recycling. Proper cooling system maintenance and good recycling practices can mitigate the harmful effects of antifreeze on our environment.

Every year about 10,000 cats and dogs are victims of accidental poisoning by ingestion of antifreeze. It has a sweet taste that small children and animals can find attractive. If ingested, antifreeze affects the central nervous system and can cause death. A couple of states in the U.S. require the addition of a bittering agent to make antifreeze less tasty to children and animals.

While ASTM (the American Society for Testing and Materials) was in the process of developing industry standards, the OEMs (including General Motors, Ford, Chrysler, Caterpillar and Cummins) developed proprietary standards in response to the demand of the field. After developing these standards, they issued company- or process-specific approvals. Testing and approval programs varied in intensity, however they were primarily based around virgin engine coolant requirements.

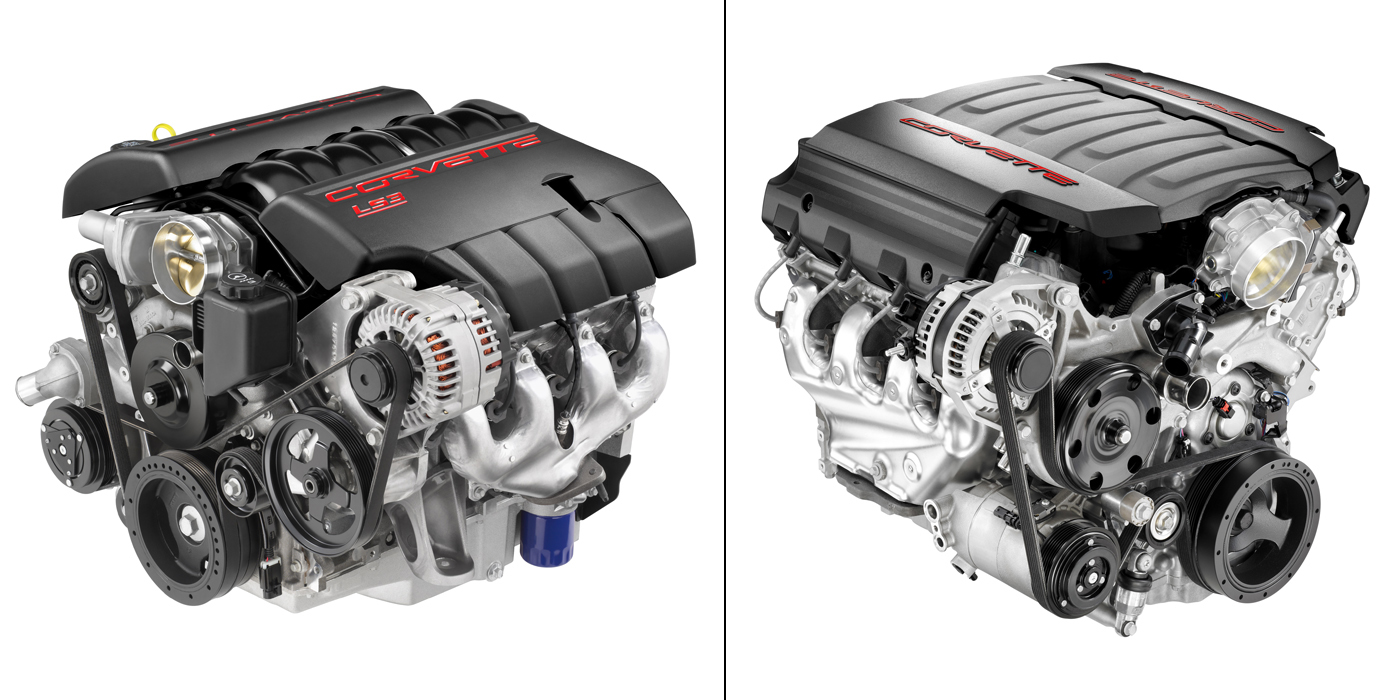

Interestingly enough, standards for pre-mixed coolant were in the mix as well. With many bi-metal or all aluminum engines, loaded with electronics throughout, the worst potential enemy to your engine coolant could very well be the water that you use for your 50/50 mixture. What kind of water quality issues could you be facing?

• Calcium and Magnesium – Calcium and magnesium salts form scale on hot heat exchange surfaces. Scale impedes heat transfer and causes localized hot spots that results in engine overheating and component failure.

• Chloride and Chlorine – All municipal water supplies contain chloride and chlorine. Chloride is very corrosive to all cooling system metals, especially aluminum. Chlorine forms additional chlorides in the cooling system.

• Sulfate – All municipal water also contains sulfate that contributes to general corrosion and scale formation.

• Oxygen – Deionized water doesn’t taste good due to the lack of oxygen and certain minerals. Tap water, however, is full of oxygen and other minerals making it suitable for drinking and aquariums. Oxygen contributes to metal corrosion and depletion of inhibitors. Water with low oxygen is preferred for engine coolant.

If that isn’t bad enough, even if correct water is being used you may have mixing mistakes. Cooling system problems can often be caused by improper dilution of the coolant/antifreeze with water. These problems include:

• Improper ratio of concentrate to water;

• Not stirring thoroughly to mix the water and concentrate;

• Mixing the concentrate and water in a dirty container;

• Pouring the concentrate and water into the radiator without first mixing them.

So if you have used water from your garden hose to mix your coolant, you may be overdue for cooling system maintenance because deposits have been building up. Maybe you already have had the radiator rodded out – unfortunately, the engine block and heads have the same deposits. A quick acid flush (which can attack copper, aluminum, and brass) will NOT remove what took years and tens of thousands of miles to build up.

The other issue with using water from your garden hose is that it has a detrimental effect on the additive package in your coolant to keep the system clean and free from corrosion, ensure long life of the seals and maximize the cooling capability. So you can see how you could actually be better off to use pre-mixed antifreeze and keep the cooling system clean in the first place.

Made using ethylene glycol or propylene glycol, antifreezes differ in more than color or they can be the same color but use different inhibitor packages. Antifreeze manufacturers use a number of different corrosion inhibitor packages that have descriptions such as Heavy Duty Conventional with Supplemental Coolant Additives (SCA); Low Silicate Conventional without SCA; OAT (Organic Acid Inhibitors); and Hybrid OAT. Each unique antifreeze chemistry formulation performs differently.

U.S. government specification CID-A-A-52624 covers requirements for ethylene glycol and propylene glycol antifreeze and allows three different concentrations: 100%, 60%, and 50%. The specification requires the antifreeze “to be suitable for use in all administrative vehicles, construction and material handling vehicles and equipment, and military ground combat and tactical vehicles and equipment.” The U.S. government encourages the use of recycled antifreeze.

Unfortunately, the vast majority of recycled antifreeze in the USA does not meet these standards. If you want to verify that the recycled coolant that you are purchasing is correct verify that you have D 6471, Specification for Recycled Prediluted Aqueous Glycol Base Engine Coolant Light-Duty Service; and D 6472, Specification for Recycled Glycol Base Engine Coolant Concentrate for Automobiles and Light-Duty Service.

“Light duty” antifreeze is intended primarily for gasoline-engine passenger car applications. “Heavy duty” antifreeze is intended for diesel engines in both on- and off-highway applications. Diesel engines in heavy-duty truck and construction equipment have more severe corrosion prevention requirements than gasoline-engines in passenger cars and therefore require more corrosion inhibitors. Using “light duty” antifreeze in an over-the-road tractor will cause cooling system problems unless an SCA in proper amount is added to the antifreeze.

The last thought that I leave you with is this: if you have recycled coolant that has not gone through the process of removing corrosive chloride salts then you do not want to use this product. Chloride salts are the hardest components to remove from recycled coolant and can cause the most damage.

Recycled coolant is a great way to be environmentally friendly and an easy way for all of us individually and corporately to be “green” with little or no effort. Just make sure that you have a product that meets the standards and it is every bit as good as a virgin coolant – and in some cases, even better.

Roy Berndt has decades of machine shop experience. He is the EDS Data Acquisition Contractor for the Production Engine Remanufacturers Association (PERA), and Program Manager for PROFormance Powertrain Products, a PER in Springfield, MO. Roy can be reached at [email protected].