Rebuilding The 4.0L:

Blocks

There are two block castings, a 4593586AA and a 4593586AB, but they’re both the same and they’re identical to the late 3.5L – except for the big mains. They’re easy to tell apart because there’s a small ‘3.5L’ or ‘4.0L’ on the block right below the casting number.

Crankshaft

The 4.0L motor has a forged steel crank that looks just like the one that’s used for the 3.5L, but the mains are bigger – they’re 2.717” instead of 2.5202” – and the stroke is 10mm longer so it measures 3.58” instead of 3.189”. This crank is easy to identify because it has “4 0” forged on the counterweight right behind the third rod journal. The big main bearings for the 4.0L are available in the aftermarket now.

Connecting Rods

The 4.0L uses the exact same rod that showed up in the 3.5L beginning in ’07, even though it has a longer stroke. It’s easy to identify because it’s a forged steel rod with a cracked cap that has “4AA” on it along with a tapered, small end that has a special bushing in it. Oversize OD rod bearings are available, but no one offers the special pin bushings so we’re having them custom made for this application.

Pistons

The piston for the 4.0L looks a lot like the one that was used with the new rod in the 3.5L beginning in ’07, but the compression height is 5.0mm shorter because the stroke is 10.0mm longer. Modifying the compression height of the piston allowed Chrysler to use the late rod from the 3.5L along with a common deck height so they could install the same heads and timing components on both engines. This piston is available from DNJ, too.

Rings

The 4.0L uses the same 1.2mm/1.5mm/2.50mm rings that were used for the late 3.5L beginning in ’07. Good luck assembling the short block with the narrow oil rings.

[inpost_gallery post_id=3420 group=”3″]

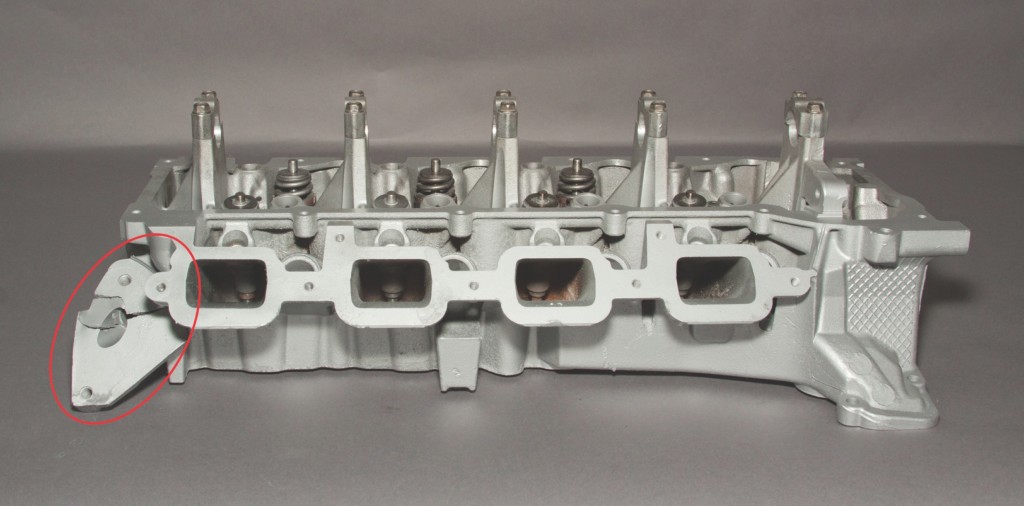

Heads

The 4792728AA or 4663894AC head castings that came on the 4.0L are the same ones that were used on the 3.5L beginning in ’04. Both of these heads have provisions for EGR so we always plug the holes to make sure that the customer doesn’t forget to plug the one that isn’t needed for his application. Everything else that’s up topside, including the cam followers and rocker assemblies, is the same except for the cams.

Camshafts

The cams for the 4.0L are unique to this application. Chrysler says “they have a higher lift/profile for increased performance” and that the “intake lobes are splayed for reduced NVH.” Both cams can be identified by the raised cast ring around the barrel behind the fifth lobe. The right hand cam is a PN4593616AA and the left hand one is a PN4593618AA. Chrysler recommends replacing the bolts for the cam sprockets any time they’re removed.

Timing Components

All of the timing components used on the 4.0L are the same as the ones found on the late 3.5L including the sprockets, tensioners, pivots and timing belt.

Front Covers

The only difference between the front and rear wheel drive long blocks is the inner front cover. The one for the FWD cars is a 4892137AA/AB/AC that has a flat pad on the top with three bolt holes that are used for the torque axis motor mount. There are three different castings with AA/AB/AC suffixes and Chrysler still lists two different part numbers, but we’ve seen all three of them and couldn’t find any difference, no matter what Chrysler says. There are three different castings for the front cover that’s used for the RWD motors, too, with a 4892266 casting number that has AA/AB or AC suffixes. There are some subtle differences between them, but Chrysler has superseded all of them to the latest version with the AC suffix, so they can all be interchanged.

Final Thoughts On The 4.0L

The 4.0L is easy to catalog because there’s only one short block along with two long blocks that have different front covers, depending on the application. It’s easy to build now that all the parts are available, because it’s just an overgrown 3.5L with a different block, crank, pistons and cams. There are plenty of the 4.0L motors out there in cars that are worth fixing, so you should get some calls.

The 3.6L Pentastar

Meanwhile, the new 3.6L Pentastar motor that replaced all six of the “old” Chrysler V6 engines is very impressive. It’s available in almost everything Chrysler builds including their RWD cars, all of their minivans, the Jeep Grand Cherokee, the Dodge Durango and the Ram pickup and it performs well in all of them. In fact, it’s so versatile that the engine that’s in the pickup trucks is the same one that’s used in the cars except for the intake manifold. These engines make 90% of their peak torque from 1600 rpm all the way to 6400 rpm while making over 300 horsepower and getting 25 miles per gallon in the pickups and full-sized cars.

So what makes the 3.6L so special? Here’s what we know about this new motor:

The block is a lightweight, aluminum die-casting that weighs 20 pounds less than the aluminum 3.6L GM block. It has forged rods and cast pistons that are cooled by the oil nozzles that are located in the crankcase. The variable displacement oil pump that reduces oil pressure below 3000 rpm under the right conditions is in the front cover.

The DOHC aluminum heads have 24 valves and dual independent cam phasers. There’s just one pair of heads and there’s only one pair of cams used for all of these engines. The single exhaust outlet that’s integrated into the head has “flow paths” cast inside the head to create the same flow as a traditional exhaust manifold without having to bolt an external manifold on the head, so it’s just as efficient and it’s easier to package the engine in a variety of applications, according to Chrysler.

The original engine has 3.6L/220 cubic inches, but the architecture was designed to allow Chrysler to build bigger or smaller versions ranging from 3.0L to 4.0L and everything in between, so you can expect to see some different combinations including a 3.2L that is due out next year. This engine family was designed to support MDS, direct injection, ‘MultiAir’ and twin turbos, so there’s definitely more to come. The word on the street is that there will be a twin turbo motor making 420 horsepower in 2015!

Chrysler has installed the 3.6L in nearly a third of the vehicles that they have produced since 2011 and it’s been nearly trouble free since day one. There were a handful that had phaser problems and a very small percentage that had a slight machining error that affected the heads according to my sources, but the engine has performed well with a minimum of problems in a wide variety of cars and trucks since the beginning.

They’re all VIN ‘G’ motors and they all share the same short block, heads and cams, so they’re virtually identical as far as the rebuilders are concerned, but they have different intakes, sheet metal and accessories, depending on the application, so the complete engine assemblies aren’t always interchangeable, in spite of their similarities. Hollander lists five different engines for ’11 –’12 and we know that there’s at least one more in ’13 because the engine in the Ram pickup has a unique intake manifold, so getting the right take-out engine could be a bit of a challenge.

Now that we have updated all the Chrysler V6 motors, let’s take a look at a couple of the V8s, starting with the 4.7L engine that came with dual spark plugs in ’08. All of these engines are still either a VIN ‘N’ or ‘P’, depending on the year and the application.

THE DUAL PLUG 4.7L V8

Chrysler updated the 4.7L with a new pair of heads that have slightly different intake ports and noticeably bigger exhaust ports that are squared off on the top along with a revised combustion chamber that has dual spark plugs, just like the Hemi. The dual plug 4.7L makes a very respectable 300 horsepower, so it’s become the standard engine for the Ram pickup. It appears that one long block fits everything from ’08 through ’12 according to the information we found on the Hollander interchange site and in the Chrysler parts book. There may be different oil pans, intake manifolds, front covers and accessories used, depending on the vehicle, but the block, heads and all the internal parts stayed the same year after year in every application, so we’re going to catalog one long block for everything.

Blocks

Chrysler continued to use the same block that’s been around since ’04 for the dual plug motor. It’s the 53022033AA casting that has the three extra bolt holes on the driver’s side that were originally used to mount the front differential on the 4×4 Durango way back then.

Crankshaft

Chrysler used an all-new crankshaft (look for “288AA” forged on the front counterweight) for the dual plug motor. The pistons and the rods are considerably heavier, so some of the counterweights are longer and they have square ends instead of the bull-nosed ones found on the original cranks. The early and late crankshafts can’t be interchanged without some serious modifications, so don’t mix them up. The dual plug engine uses the NGC computer so it still has the tone wheel with 32 notches.

Con Rods

The connecting rods are real, old time forgings instead of the powdered metal ones that are used in most engines today, but they have a cracked cap and there’s no notch for a tang! The small end is tapered like the one on the 3.5L/4.0L rod, but it has a press fit pin. These rods look a lot different than the original powdered metal rods so they’re easy to tell apart, but they can be identified by the number ‘213AB’ that’s forged on the big end of the rod, too. Our samples all weighed 508+/- grams which is about 50 grams more that the old powdered metal rods, so they’re definitely not interchangeable with the early ones, even in sets.

Pistons

The pistons for this motor are unique and they weigh about 25 grams more than the original flat tops. They have a small dome with two valve reliefs and a single trough across the top so there’s not much room left in the chamber at top dead center with the 9.8:1 compression ratio. It looks like Chrysler is using the piston to help manage the combustion process along with the shape of the chamber and the location of the dual spark plugs.

[inpost_gallery post_id=3420 group=”4″]

Heads

Both of the dual plug heads are all new. The one on the right is a 53022128AA casting and the one on the left that has a pad for the EGR valve is the 53022129AA casting.

All the intake and exhaust ports have been modified and the chambers are unique to this application. Most of the parts used for the heads including the valves, springs, retainers, stem seals and lifters were revised to fit these new heads, too. In fact, the cam followers appear to be the only parts that are carried over from the earlier heads

Camshafts

The cams were updated, too. Chrysler machined the journals on a solid, steel bar along with some splines that were used to locate the powdered metal lobes that were pressed onto the bar. These cams are physically interchangeable with the old ones because the bore spacing is the same and the valves are all still in the same place, but we expected to see some differences in the new cams – until we ran them through the ‘Cam Doctor’ and discovered that they’re absolutely identical to the hollow ones in every spec and dimension.

Chrysler hasn’t superseded part numbers for the original cams to the new ones, but they have shipped us the new, solid cams packaged under the old part numbers, so apparently they’re the same in spite of the new heads and the slightly higher compression ratio that’s used for the dual plug engine. The right hand cam is a PN 53021984AA that has 53021980AA etched on the barrel and the left cam is a PN53021983AA that has 53021979AA etched on the barrel. By the way, the new cams cost less if you order them under the old part number.

Other Parts

There are only a few other parts that are common to both engines. The cam sprockets, tensioners, oil pump and lower gasket set are all the same, but that’s about all that appears to be interchangeable between the ’07 and ’08 engines.

5.7L HEMI

And then there’s the ’09 Hemi with VVT. It’s really an all new engine with a different block, crank, rods, pistons, cams, heads and timing set. The block is a 53021319DK casting and the crank is a 53021300BB. The heads appear to be identical, but one of them is a 53021616DD and the other one is a 53021616DE casting and Chrysler lists them separately, so there must be a difference of some kind. We don’t know much more about these engines except that there are five different cams including the one for the hybrid motor that was supposedly built in ’09.

Here’s the list of all the different cams along with their applications:

1. VVT only with a high performance profile for the Challenger with a manual transmission.

2. VVT only for the 2500/3500 pickups with a profile that’s designed for the heavy-duty trucks.

3. VVT plus MDS for the RWD cars with automatic transmissions, all the Jeeps and the ’11-’13 Dodge Durangos.

4. VVT plus MDS along with the “short runner valve” (SRV) for the “active intake” that’s installed on all of the Ram 1500 pickups and the ’09-’10 Dodge Durangos.

5. VVT plus MDS for the ’09 hybrid Durango. They didn’t build many of them so there isn’t even a part number for the cam in the parts book, but it’s probably a special cam that came with a unique phaser that was designed for “late intake closing,” just like the one that was used for the hybrid LS motors in the GM pickups.

None of the cams are interchangeable, but they’re easy to tell apart because there’s an ID ring in front of the fifth journal that has a varying number of grooves that are machined in different locations so you can identify each cam by type and application, according to Chrysler. Be sure to use the right cam when you build one of these engines or you will have a comeback. The bad news is that they’re all VIN ‘T’ motors, so you will have to know the exact application and find out whether or not the vehicle has MDS or/and an “active intake” in order to supply the right engine.

Conclusion

So that’s the story. Chrysler has simplified their vehicles by eliminating three engine families since ’07 while adding the four cylinder “World Engines” along with the all new DOHC 3.6L V6 and updating both the 4.7L and 5.7L V8s with new technology that improved fuel economy, performance and emissions.

And, there’s more to come, because they will have to continue to improve their engines with more new technology in order to meet the higher CAFE standards that are yet to come, so you can expect smaller engines with lightweight blocks, sophisticated heads, new rods and pistons, narrow rings, direct injection and a high tech valve train like MultiAir along with superchargers and turbochargers. With all that in mind, it will be interesting watch the evolution of the Chrysler DOHC family and their new four cylinder “Tigershark” engines along with the Hemi.` It’s time for everyone to “buckle up in lane two” as they say at the racetrack.

Doug Anderson is Manager of Technical Services for Groom