Internal Issues

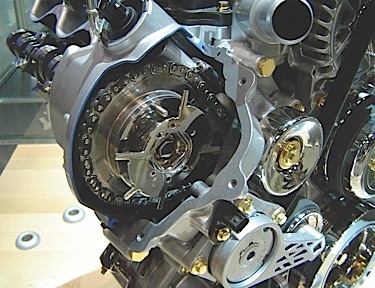

The 4.6L engine has a good reputation for reliability, but like any engine it has had a few problems. The relatively long timing chain that drives the overhead cams is tensioned by plastic guides on many of these engines.

As long as the oil is changed regularly and a good-quality oil is used (along with the correct oil filter that contains an anti-drainback valve), the timing chain holds up well. But if oil changes are neglected, cheap-quality oil is used or a filter that lacks an anti-drainback valve is installed, guide wear and/or breakage can become a problem, and the timing chain may fail.

A symptom of chain guide wear would be chain rattle following a cold start. If a chain guide has broken, the chain tensioner can overextend and rotate, changing the timing of the affected camshaft. This, in turn, may cause a rough idle and possibly set a P0300 random misfire code and/or lean or rich codes.

The cam phasers on the 3V 4.6L engines can also tend to be noisy, producing a light knocking sound at idle. This is normal, Ford says. But if the noise is excessive (under 1,200 rpm) or there are cam-related fault codes, the problem may be a bad variable cam timing phaser that needs to be replaced.

[inpost_gallery post_id=4898 group=”1″ sc_id=”sc1492621272962″]

Fore more on this noise issue, click here.

If you encounter a 2007-’08 Mustang, Expedition, Explorer or F-150 that makes a strange whistling or hooting noise for a few minutes following a cold start, the problem may be a bad serpentine belt idler pulley. Ford TSB 09-9-7 says replacing the grooved nylon FEAD (front end accessory drive) idle pulley with P/N 6L3Z-6C348-A should eliminate the noise.

The oil pump on the 4.6L engine is a front-mounted crankshaft- driven pump. The 2V, 3V and 4V engines all use different oil pumps, so make sure you get the correct one if you have to replace a pump. The 4V oil pump flows more oil than the 2V pump, and the 3V pump flows more than the 2V and 4V pumps.

If you are replacing an oil pump, the pump gears must be perfectly centered on the crank so that the gears won’t bind against the side of the pump housing. This is best done with the block out of the car sitting up on end so the crankshaft is vertical and centered in the main bores.

If you are replacing the oil pump, it’s a good idea to also replace the pickup tube inside the oil pan if the engine is being totally rebuilt or has suffered a catastrophic piston or bearing failure that may have spewed debris into the crankcase. Debris lurking inside the pickup tube may be drawn into the new oil pump. Also replace the pickup tube O-ring and make sure it is properly seated so air won’t be drawn into the pump.

Also, you need to prime the engine’s lubrication system with a pressure primer. Add oil to the primer and pressurize the tank with a shop air hose, then connect the supply hose to the oil sending unit fitting on the side of the engine.

Open the tank valve to allow oil to flow into the engine’s lubricating system and pump. It’s also a good idea to turn the crankshaft one full revolution by hand before starting the engine. This will help spread the oil on the crank bearings.