Available in the U.S. for the Veloster Turbo passenger car, the turbocharged engine features a maximum output of 150 kW (204 HP), an increase of 46 percent compared with Hyundai’s standard 1.6-liter GDI engine

BorgWarner supplies its leading turbocharging technology for Hyundai’s new 1.6-liter turbocharged gasoline direct injection (T-GDI) engine.

Available in the U.S. for the Veloster Turbo passenger car, the turbocharged engine features a maximum output of 150 kW (204 HP), an increase of 46 percent compared with Hyundai’s standard 1.6-liter GDI engine. The Veloster Turbo has also been available in Europe since October 2012.

“Combined with Hyundai’s direct-injection technology, BorgWarner’s turbocharging expertise helps achieve a fuel efficient and responsive engine for an exhilarating driving experience,” said Frederic Lissalde, president and general manager, BorgWarner Turbo Systems. “We are very pleased to expand our successful relationship with Hyundai Motor Company through our supply of advanced turbocharging technology for gasoline engines.”

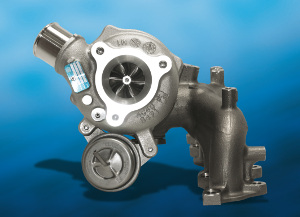

To develop a state-of-the-art engine featuring low-end torque, responsiveness, instantaneous power delivery and improved fuel economy, Hyundai matched BorgWarner’s K03 twin scroll turbocharging technology with its GDI system.

Compared with a single scroll turbocharger, twin scroll turbocharging recovers more energy from the exhaust gas and improves responsiveness even at low rpm. BorgWarner’s twin scroll turbocharger separates the exhaust gases of the cylinders and minimizes parasitic back pressures.

BorgWarner further optimizes the exhaust gas flow to the turbine wheel with an optimized channel design. Torque of 270 Nm (199 lb-ft) is available over a wide engine speed range, from as low as 1,750 rpm and up to 4,500 rpm.

In addition, BorgWarner integrated the exhaust manifold into the stainless steel turbine housing to reduce size and weight while optimizing heat energy recovery for better efficiency.

For more information, visit borgwarner.com.