Many Chevrolet Corvette ZR1, Z06 and GS models built between 2006 and 2013 are equipped with a dry sump engine lubrication system.

This high-performance system operates differently than a standard engine lubrication system and requires a special procedure when checking the engine oil level.

When adding engine oil to these vehicles, care must be taken to avoid overfilling the system. Overfilling may cause over-pressurization, which may result in damage to the engine and emissions system components. Also, if the amount of engine oil in the system is unknown due to repairs or other causes, the entire system should be drained and refilled with the correct amount of engine oil.

In order to get an accurate reading, the oil must be warm and the vehicle must be on level ground. A cold oil level in the dry sump tank may not indicate the correct amount of oil in the system.

Under normal operating conditions the engine oil pan does not store any oil, but if the vehicle has been parked for an extended period without the engine being started, some oil will seep back into the oil pan, reducing the amount of oil held in the dry sump tank. There could be no engine oil at all showing on the level indicator.

This condition is normal since the level indicator is designed to read the engine oil level only after the engine has run long enough to reach normal operating temperature. Do not add engine oil based on cold engine level indicator readings. The engine oil level on the level indicator will also be inaccurate if checked while the engine is running.

Service Procedure

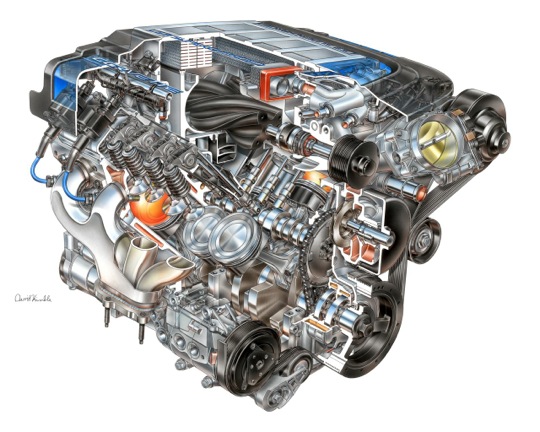

Follow the service procedures, precautions and capacities listed in ALLDATA Repair before servicing the engine oil, oil tank and filter. The yellow-looped level indicator is located on the dry sump engine oil tank (No. 1 in image). The oil tank is external to the engine and is located on the passenger side of the vehicle.

Checking Oil Level

1. To obtain an accurate engine oil level reading, warm up the engine to at least 175°F (80°C).

2. Once the engine is warm, turn it off.

3. Wait at least five minutes (but not more than 20 minutes) to allow oil to drain and settle in the engine.

4. Remove the level indicator from the external engine oil tank and clean it with a lint-free paper towel or a cloth. Re-insert the level indicator into the external oil tank, pushing it all the way in until it stops.

5. Remove the level indicator from the oil tank and read the level on the cross-hatched area. Oil levels that fall in the cross-hatched area are normal.

Oil System Debris and Flushing

If replacement of the engine becomes necessary, or any failure is experienced that may cause debris to enter the oil supply, the remote oil tank must be disassembled and flushed. Additionally, the oil cooler and both oil cooler lines should be replaced. The remote oil tank can be removed from the vehicle and separated into two halves to facilitate a thorough cleaning.

Written by the ALLDATA Community Automotive Diagnostic Team, a select group of automotive experts dedicated to helping technicians fix hard-to-repair vehicles more efficiently. Meet the team by visiting support.alldata.com/alldata-community.