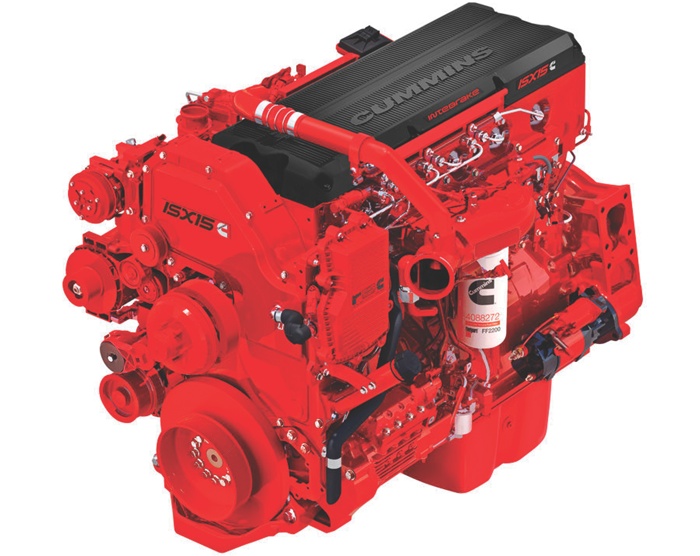

![cummins ISX 15[1]](/wp-content/uploads/cummins-ISX-1511-300x238.jpg) Each newer version of the Cummins ISX 15 engine gets more fuel-efficient as the technology keeps advancing. Cummins has stated that the newest ISX 15 can deliver up to 2 percent better fuel economy than previously reported. The newest Cummins ISX 15 operational efficiency actually delivers more horsepower than in older ISX engine models.

Each newer version of the Cummins ISX 15 engine gets more fuel-efficient as the technology keeps advancing. Cummins has stated that the newest ISX 15 can deliver up to 2 percent better fuel economy than previously reported. The newest Cummins ISX 15 operational efficiency actually delivers more horsepower than in older ISX engine models.

The ratings on the ISX 15 range from 400-600 hp (298-447 kW) with 2050 lb.-ft. of peak torque. The SmartTorque system Cummins developed adds roughly 200 lb.-ft. of extra torque to the top two gears of the engine.

So what do diesel engine builders need to remember when working on the ISX?

1. Pay special attention to the spring-loaded cam gear.

2. You’ll need to use a special tool for the front and back seals. Special puller tools to pull off the crankshaft are available from several different tool suppliers.

3. Back off the spring-loaded tension before unloading it.

4. Totally non-interchangeable between ISX and QSX. Use all specified parts.

5. Pay attention to differences between ISX engine blocks. Some have EGRs and others do not. You can use both types of engine blocks if need be; just realize that the water fittings need to be fitted with frost plugs.

6. Everything on ISX and QSX is heavy-duty including heavy-duty cams.

7. Make sure to set the idle gear properly. ISX has floating gears as they are on a floating hub. The gears float because of the required backlash. There also must be torque between all of the gears and the timing must be set properly between the gears. In a running engine the gears must be unloaded. Only the Detroit 60 Series has similar floating gears.

8. Pay special attention to the dual overhead cams: one is for the valves and injectors and the other is for the Jake Brakes.

9. Overall, strictly follow the service manual. Stick to OEM specifications and tolerances as this engine is a very precise piece of equipment and allows little room for error.

From the staff at Capital Reman Exchange http://capitalremanexchange.com/