You know how it feels when you explain something over and over and the person just doesn’t seem to get it?

You know how it feels when you explain something over and over and the person just doesn’t seem to get it?

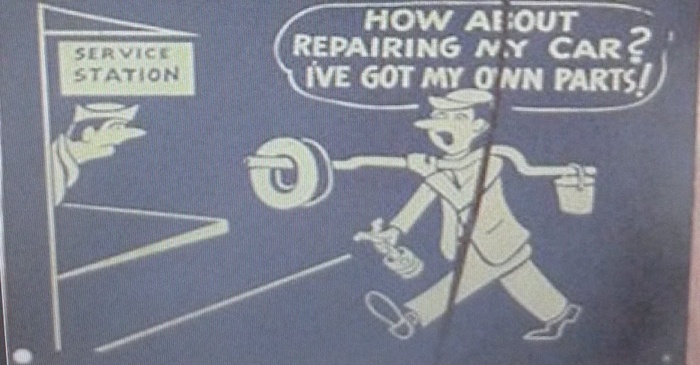

Some seven years ago I broke into the pages of Engine Builder with an article about dealing with what I called walk-in parts. Off and on again I’ve gotten back on that bandwagon because the topic just keeps getting more and more relevant. Every day, the more shops I talk to, the more I hear how the customer wants to supply his own parts.

If, during the initial consultation your customer starts talking about having you call him with the “sizes,” you can be sure he thinks he can just buy the parts himself. You should respond in your own best interest and explain to him how you sell parts here as well and your business runs on the money you make both running the machines and the profits you make selling parts. Without one, the revenues from the other must increase to keep your doors open.

You need to determine the rules of your shop and operate by them. Once you set the rule, post it on the wall for everyone to see. You’ve now given yourself something to fall back on – you don’t have to think about it or apologize for it, you just do it.

If you’re doing a valve job and the guides are worn, you know you can’t cut a good seat. You inform the customer that there will be additional labor needed to do the job correctly. And you know that “correctly” is the only way you’ll approach the job. Why should supplying the bill-of-materials for the job be any different? If this is the rule of the house, then that’s how it’s going to be. Then, if the decision goes any other way, you have no one to blame but yourself.

Things are much different when the customer shows up with the block in the back of the truck and the pistons in hand. If you’re really good (or really determined) he’s going to walk out of your shop, pistons still in hand, ready to ship them back to wherever they came from. Honestly, though, if you’re like most of us, this won’t happen. You’ll swallow your pride and just take the job as it’s presented.

impulse items, a few things

everyone needs to finish an engine project and a few empty boxes from pistons, rings and a camshaft that will announce “Parts Sold Here.”

So before you find yourself in that position – trying to decide if you should take the job, refuse the job, or try to figure out how to tell the customer how it’s going to be – you need to have a plan. For your survival, no parts sale must equal a higher labor rate. And yes, you can do this.

The Direct Approach

It continues to be very difficult for the machine shop to sell parts like head sets and head bolts to the repair shop. Although the repair shop owner doesn’t want his customers to demand that he use parts they’ve bought, for some reason it’s okay when he does it to the machine shop. Well, I recently met a shop owner who has had enough of this double standard.

He told me how he had just taken a call from a new repair shop and they had asked for a quote on some head work. One of the first things he asked was if they’d be purchasing the head gasket set and head bolts from him to go with this job. When the shop foreman answered honestly that no, he buys his gaskets from his parts supplier, my guy calmly explained that his customers buy their gaskets and bolts from him and if that arrangement is acceptable, then he’d very much like to take care of their job. The potential customer was taken aback by this statement and said he’d have to talk to management about this.

I say, good for him! It’s his business, his house rules, his warranty to stand behind, his potential future and how can any reasonable person not see this if explained correctly. Incidentally, the job showed up at my guy’s shop and he will be supplying all the parts for the job. In the good old days, I remember the shops I worked for and many I have sold to found half their revenues from parts sales. What percentage would you say it is today? Low? Exactly!

I recognize that the goals I’ve set may not be the same ones you’ve set, but there is a point at which our mutual goals are similar. This intersection is at the corner of profits and cash flow.

Every business needs cash flow from profits to survive. Since my business needs your business, my goals should (and do) include helping you reach your goals. Your goals should include your customer’s goals and I’m hoping your goals include the success of my end of the business as well. This economic cycle we all profit from does not start or end at each of our own front doors. No, it begins downstream somewhere with an opportunity, brought to your attention, usually carried in all oily and dirty by your customer, to your front counter.

Your customer’s goal to repair, machine, improve or modify something meets your goal to make cash or profits, which require my goal, of selling parts.

Since parts are pretty much a necessity, always have been and always will be, why are we constantly walking away from this potential profit center? Over the past 40 years I’ve searched, but cannot find one similar industry where the business or service provider does not also supply the bill-of-materials.

I believe that it’s in your best interest to avoid assembling engines with parts you did not sell. The reason for this is twofold. Not only are you missing the chance to make profits from the parts, there are warranty concerns.

I don’t know when you last had to spend the day in small claims court, but this isn’t something you’d wish on anyone. From what I hear the business is likely going to lose. There is such a strong move toward consumer protection that court decisions continually fall in favor of even the most ridiculous consumer claim and against even the best-prepared business owner. Trust me when I say, take care of your customers. Don’t waste your time in court.

The consumer comes to you trusting that everything will be done and done correctly. If you say yes to “walk-in parts,” there may be an implied agreement that you will make sure they are right and in perfect condition before you install anything into your freshly machined component. To the courts, you are the professional and the last (and maybe only) person to see that part before installation. Is it really too much to understand the perception that this is now your responsibility? Unfortunately, it happens.

Consumers may be more price-conscious than ever, but given the right circumstances, they want convenience. I believe you can give them what they want, make what you need, do the whole job and consumer satisfaction will build your reputation and business. There are businesses out there doing this every day, quite successfully.

When Should You Discount?

You must tie the parts sale to the labor, which might mean raising your printed prices so you can discount the labor when you also supply the parts. This is a business strategy that sends several messages to your customer. First, it says that contrary to popular belief, you do sell parts. Maybe if we cleaned up some of those old cores and some of the junk laying around, we could find a space to set up a display of impulse items, a few things everyone needs to finish an engine project and a few empty boxes from some pistons, rings and a camshaft that will announce “Parts Sold Here.” For my customers, I’ll even supply the signage in the form of a poster of parts with the heading stating a discount on labor is available when parts are purchased. Once you decide that the job is not complete until you get the parts sale, you’ve taken the first step in taking back control.

Another way to look at discounting your newly raised labor price is to “kit” your labor. The strategy I call “The Package” is very simple and can help you quote jobs faster and helps protect you from price shoppers. You may buy engine kits from a supplier because you know it will net you a better price on a grouping of parts that will be necessary to complete a job. Just approach your labor the same way. Add up the labor it will take to fully machine a short block, round it off to something that sounds attractive and offer this price when customers purchase the engine kit or necessary parts from you for a job. You will have a different package for different cylinder counts and you may need to consider different engine styles just as you would a different valve job price for a DOHC engine vs. an OHV engine.

This can also be used to quote a complete engine job. Add the kit, the machining kit package, valve work and assembly. It may not be perfect, but it will give you a quick number to use to estimate a job, or to compare to the guesstimate you were about to quote.

Check All Appropriate Boxes

I also suggest you reexamine your current work order. Are you charging for everything you do? Consider the time you spend with a micrometer in your hand. If you are boring and honing a block and you’re also supplying the pistons, you’ll be putting the mic on the pistons to check the size and bore your holes accordingly. But what if you choose to do a job using the customer’s supplied pistons? Since you’ll be responsible for the job, show your customer that you’ll certainly check his parts and you’ll of course charge him for that time. Under your entry to bore cylinders just add a charge for “mic and check pistons.”

If you sell the parts, you show your customer that there is no charge for getting out your tools. If he supplies the parts, you charge for the time it takes to make sure they are in good shape and correct. This may sound petty to us, but when it’s on the work order it becomes an amount of time and it becomes the consumer’s decision since they decided to shortcut the process by purchasing their own parts.

Look at every category of your worksheet. There are easily a dozen jobs you do for free, but might be able to charge for your time.

I’ve talked about other strategies for success, including “selling your knowledge,” but if it seems like I’ve put all the responsibility on the machine shop, you’re wrong. I’d also like to challenge the manufacturers, suppliers and distributors to take some of the blame for the difficulty we have with parts. The pie is only so large, and it seems today there are those in a search to carve out their own piece at the cost of everyone else, including their customers. The president of a large auto parts manufacture was recently quoted as saying, “We are in a race to the bottom.”

How can you not lose this race? You can’t change all of these distribution problems on your own, but you can stand up to them in a couple of ways. First, look at the sales practices of the companies whose products you select – do they support your efforts? Two, take back control of your own business. I’d try to quote jobs, not parts and labor. If you have to quote it that way, put emphasis on the package deal and the warranty. If I were back at it, I’d love to ask the consumer what happens in their industry. Does the patron bring eggs to the restaurant? Explain that this is a business based on two revenue streams and on providing the best, finished product available.

The only way to guarantee this is to be in charge of both the labor you supply and the parts you use. I do understand that there are actually two different consumer markets, so I suggest you do as well and offer both price structures that fit their choice of marketplaces. I write this in an effort to see you finish in a race to the top, not as a participant in the “Race to the bottom.”