The new GLX-3 Laser Welders from Branson Ultrasonics, a business of Emerson, delivers clean, high speed laser welding of large-format plastic parts with more complex geometries to meet the growing needs of automotive, appliance, medical, filtration, and other applications that require particulate-free welds with superior aesthetic quality.

The new GLX-3 laser welder incorporates advanced features, including Branson’s patented Simultaneous Thru-Transmission Infrared (STTIr) process, which heats, melts, and joins the entire weld line of two or more parts simultaneously. Compared to scan or trace laser welding processes, which must travel the entire length of the weld line to accomplish heating, Branson’s STTIr results in a significantly faster weld cycle on large parts, and more precise melt of the weld line.

Thanks to this innovation, the GLX-3 laser welder can now deliver cycle times as fast as 0.5 to 5 seconds on weld lines of 2.0 meters nominally, depending on part material and geometric complexity – a result far faster than trace laser welders of comparable capacity. Throughput speed is increased further with automatic tool changes, which typically can be performed in under five minutes. In addition, their exclusive STTIr technology enables the precision welders to accommodate variable weld widths, delivering weld depths of 1.0 mm or more, yet holding tight tolerances on weld depths as shallow as 0.05 mm or less.

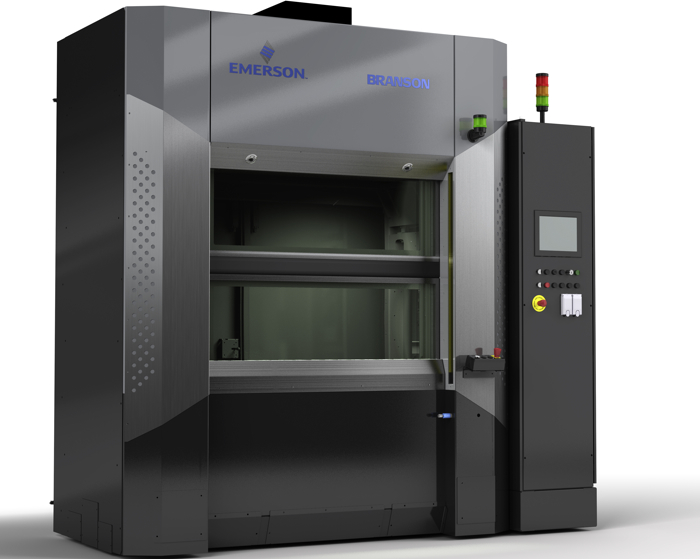

The GLX-3 welder is designed for large-format parts that require greater laser and clamping power. It offers an expansive (1333 mm x 600 mm) high-speed, servo-driven lift table with a high overhead clearance, capable of accommodating single- or multi-cavity tooling with combined weights (upper and lower) of up to 500 kg. The GLX-3 offers four levels of laser power (1250W, 1500W, 1750W, and a maximum 2000W) a wider range of clamping force (1-25 kN), plus closed-loop, clamp-force control to meet the most demanding parts-welding requirements.

The GLX-3 is designed for easy use, with a 12-inch, color human-machine interface (HMI) screen based on a common global IPC architecture that simplifies training, setup, adjustment, and diagnostics. The HMI software can accommodate up to 99 different users with configurable access rights and password-protected logins. Both welders are housed in compact, Class 1 laser-safe enclosures that meet CE, ISO, and ANSI norms, with twin front doors that contain 3.5mm thick laser-safe glass for process viewing. Machine functions and safeties are managed by a dedicated safety PLC running Branson’s advanced Logic Control System, which automatically synchronizes door, lift-table, and tooling activities to minimize weld cycle times while maintaining process safety. Process cooling for the GLX-3 welder is provided by integral chillers that are linked to roof-mounted heat exchanger-dehumidification units.

Branson provides a full range of plastic welding solutions, like the GLX-3 welder, that are fast, clean, and energy efficient, able to stand alone or integrate smoothly into existing automated systems. Clients can leverage Branson’s unsurpassed industry experience through its network of people, facilities, and technical resources in the Americas, Europe, and Asia, gaining the edge they need to manufacture products more efficiently and get to market faster.

For more information: www.branson-k.de or www.BransonUltrasonics.com