If I had my current shop rate paid to me in a lump sum for every hour I spent porting and flowing heads and intakes in the ’70s and ’80s, I could build a new race car.

In ’76 when I started running Pro Stock, my wife Linda got me a SuperFlow 110 for Christmas so I could flow my own heads. “Porting” and “flow numbers” were the most popular racer/rodder buzzwords of that era. One reason that a serious Pro Stock racer would have had a flow bench back then was to verify already prepared Pro Stock heads. Back when stock castings were used there were many independent porting artists. If the head builder knew his customer had a flow bench (and more importantly knew how to use it) the chances of receiving a better product were increased. They would often put in the extra effort and produce something really special.

A pleasant surprise for me was that the flow bench turned out to be a real money maker. People came to me to port and flow their heads – some just to capture their own flow numbers or prove someone else’s port work.

As I’ve mentioned before, I ported and flowed heads and manifolds for all types of engines. I did Pro Stock and other drag racing heads as well as all brands of stock car and street rodder heads. I also did puller heads for antique farm equipment and garden tractor pullers of all types, as well as motorcycle heads, single-cylinder porting, and even porting and flowing outboard motors.

The crazy part was, many of those projects did not need my work. Many times I tried to talk eager bracket racers and street rodders out of it but as I mentioned earlier, port, polish and flow numbers were the buzzwords of the day.

I begged one guy not to have me port his heads when he brought me a pair of brand new Ford FE 1964 High Riser heads and new 8V single-plane High Riser intake still in the Ford boxes. His goal was to run in the 10s at the drag strip with his ’69 Mustang.

I assured him that a decent modest set up ’69 Mustang with a 427 High Riser and two 715 CFM Holley Carbs, would have no problem running 10s without porting the heads and intake. He finally talked me into it, and his money was good. The Mustang ran in the mid-9s with the ported engine I built for him.

A couple years later, that same guy changed to a 460 stroker and sold those Animal Jim ported High Riser heads to a well-known NHRA Super Stock racer and champion record holder. That racer, a Ford FE craftsman himself, called me and complimented me on the job I did on those heads. That made it all worthwhile.

When Enough Isn’t Enough

On my list of engine operations back then, I featured three porting packages at three price levels – $150, $300 and $500.

One of my problems always was that I would usually overdo the package. It was hard for me to stop, knowing one more step would improve the job even more. I would usually give away a couple hours just out of pride, unless some rule would not allow the next step.

Way before CNC, when porting heads was still a mania, many people tried it on their own. There were many articles and “how to” books giving details and pictures of porting. A grocery clerk could suddenly become a head porter.

Man! Some of the absolutely wrong and ruined heads I had brought to me after amateur attempts at porting were astounding. Many were totally ruined and unusable.

Another problem was rebuilding an engine for a customer with goofed up amateur-ported heads. Many I was able to save, but others were not as fortunate.

When it comes to amateur porting, Smokey Yunick put it best in one of his books. Addressing amateur backyard mechanics/stock car racers, Smokey said, “If you are compelled to port your own heads, first go buy a pair of the best, and most expensive available – then TRY and copy them.”

I remember my first attempt at porting. I was 19 years old in 1960. I had a hot ‘58 Chevy Biscayne two-door sedan with a 283, cammed and two WCFBs. After reading what to do in a magazine, I jacked my car up with a bumper jack and put cinder blocks under the frame and removed the front wheels. I took off the right exhaust manifold and ported it using a drill and tapered stone. Then took off the other side and did the same. I was just getting ready to crawl under my five-eight to reinstall the manifolds when suddenly…crunch! The jack had slipped and the cinder blocks shattered, causing my black and white Biscayne to crash to it’s front brake hubs. I was a very, very lucky boy!

I then carefully jacked the car back up. This time I used concrete blocks under the frame.

Then I got a bright idea! How would it run without exhaust manifolds? I put the wheels on and let the car down. It was about 10:30 p.m. when I started it up. WOW! What throttle response, and a crackling sound I never heard before or since! I ran it two blocks to Peoria Street. The hood was off and I could see the exhaust flames. Man, it ran great, and sounded even more awesome under power. Why the neighbors didn’t call the police I don’t know.

I returned home and put the manifolds back on in the morning. It still ran okay, but not like it did without manifolds. While that stunt didn’t seem to hurt a thing I was told later I could have warped the exhaust valves running without manifolds or headers.

Years later, when I had my own shop, I became a porting artist. It was hard work – boring, time consuming and dirty – but rewarding. Especially when I discovered using blades in the intake ports. Again, this was long before CNC machines.

I asked Jon Kaase in the early ’90s how he had time to port heads. He said he would develop one cylinder, then had a porting artist chained to a bench in the basement to copy it for the other seven cylinders.

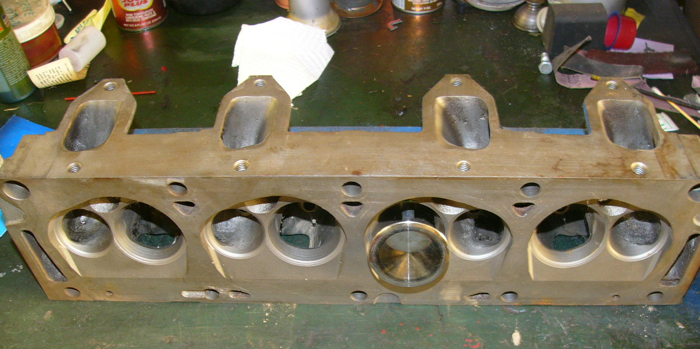

From 1975 to the late ’80s is when I did the most porting and flowing on factory heads. Most were iron and some BBC aluminum. I did most the popular USA V8s, GM, Ford and Mopar and even a couple AMC.

Besides the normal racing/hotrod engines, I also seemed to attract oddball challenging projects more than occasionally. About 1980, one Pontiac OHC project was for a 1967 Tempest street rodder. I ported the head and worked over the bowels and used 2.02 and 1.600 valves.

Babe Erson ground me a special cam. We used forged pistons at 11.5:1. I worked over the Quadrajet carb. That Pontiac had a Muncie four speed, Hurst Shifter and a 4:11 rear gear.

The results were amazing. My customer was beating healthy stock V8s, drag racing on the county roads. Then to add to it, he later put a small Miller nitrous kit on it.

Another Pontiac OHC project was for an antique tractor puller. I did much the same again, only this time, my client, a farmer near Spring Valley, IL, also was a good machinist and had a complete shop in one of his buildings. He adapted that head to the vintage tractor block. He entered an event, and right off the bat pulled the sled to Kingdom Come! I had warned him not to get too cocky, but the sanctioning body outlawed that unique marvelous engine for any future events though he did some exhibition bookings.

I don’t know what ever happed to either of those Pontiac OHC engines. My racing career went into high gear again in the mid-‘80s, and I lost track of some people for a while.

Today, the owners of the older popular V8s, with stock heads I used to port, have many choices of aftermarket iron and especially aluminum heads and special intake manifolds. It is mind boggling. Now it is a matter of choices of what to use to make sure all is simpatico.

And when the CNC machines became vogue, that really put a lot of independent “by-hand-porting” artists out business. Luckily, some customers still ask me to take the already CNC-ported new aftermarket heads to a next level.

Even if using the new aftermarket heads as is, I take them apart first and check them out. Many times I have been very glad I did. I also change those with 7-degree retainers to 10-degree steel retainers and keepers. For severe usage I use titanium 10-degree or the lightweight tool steel 10-degree retainers. Those LW tool steel came on the scene a few years ago and are only 4 to 6 grams heavier than titanium, $100 cheaper and even stronger than titanium.

Why some of the aftermarket heads come with 7-degree retainers I don’t know. Now, there are several more types of secure special keeper and retainer methods besides the old proven 10-degree.

How times change! I recently freshened up my 427 Ford Tunnel Port that is for my drag car, The Big Animal ’57 Mercury that last ran October 1979. It still had gold anodized 7-degree aluminum retainers using a roller cam. They were light and reasonably priced. I still have an assortment of them in stock. They’re very pretty gold, blue, red and plain – but I will never use them.

Of course, the spring pressures back then were not as strong as today. The cam lift wasn’t as big either.

When using aluminum retainers, it was a common practice when running the valves to take your finger with a towel and wipe the oil drain areas of aluminum trash. And you had to keep an eye on the 7-degree keepers so that they were not extruding into the retainer.

I miss flowing heads. It was a blast. Besides racing noise, working with my glass bead cabinet and flow bench is most likely the reason for my hearing problem. ν