Folks have been stroking engines as long as hot rodding has been around. Swapping Merc cranks in Ford Flatheads was a surefire recipe for a fast car. And as you can see from this as well as past Engine Builder Stroker Resource Guides, there is a kit for virtually any engine worth modifying.

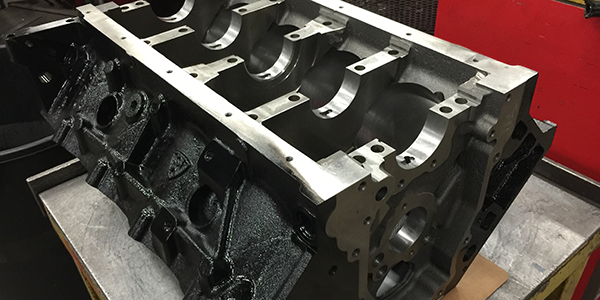

However, most engine builders worth their salt know what’s available for these engines and how to screw them together. A couple of the problem areas with these traditional V8s were cam placement and overall “case” size. While some engines like the 351 Ford Windsors have a big case and enough room for a stroker and rods to swing around, most traditional 23-degree small-block Chevys do not, and the bottoms of the cylinders often needed grinding as did the rod bolts to clear the cam.

Today’s popular engines, like the GM LS, the Mopar Gen III Hemi and the Ford 4.6L Modulars and 5.0L Coyotes are all relatively small displacement, high-output engines and could really take advantage of stroking and more displacement. The downfall of stroking the engines of the ’60s and ’70s was the inadequate cylinder heads, which could barely flow enough air for the stock displacement. So building a bigger engine would increase bottom-end torque, but little else.

Lots of engine builders were also against the shorter rods and decreased rod ratio included in commercially available stroker kits; the magic 1.9 or 2.0:1 “ideal” rod ratio described by the late, great Smokey Yunick in a Circle Track magazine was not possible. Come to find out, theoretical rod ratios were not that important anyways as today’s most highly developed, normally aspirated race engines (NHRA Pro Stock) thrive on 1.6:1 rod ratios.

The latest generation of factory performance engines not only have enough cylinder head airflow to keep up with the increased displacement, most require no special machining or modifications to install a stroker kit. The trend toward higher cam placement in the block, and in some cases overhead cams, has eliminated the cam as an interference point. Likewise, crankcase volumes have been increased to reduce pumping losses and increased efficiency. Potential areas of rotating assembly interference are the bottoms of press-in liners used by certain manufacturers, but those are easily trimmed for clearance.

One of the little discussed advantages of installing a stroker kit is that you also get to change your compression ratio for little or no charge. Granted, these late-model engines are already “up there” in compression, but it is a chance to add .5 or a full point if you run the best fuel available, have enough cooling to keep the engine temp around 200-degrees F, and possibly add a little water/methanol injection.

For those planning on using a power-adder with their stroker kits, pay special attention to the ring package and placement you will be getting on your new pistons. Supercharged, turbo and nitrous motors really need a .250˝-.300˝-thick top ring land to survive if the tune-up gets a little sketchy, and you never want a piston pin up in the ring area on a street engine. The good news is that there are so many stroker kits available, there is something for most applications and budgets. Let’s look at the three or four most popular engines:

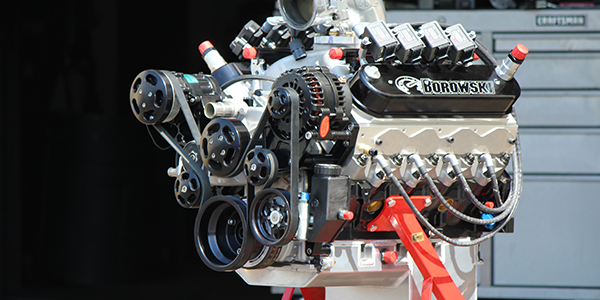

GM LS

When it comes to best “Bang-for-the-Buck” it’s hard to beat GM’s LS series of engines. They’re tough and potent – racers are taking stock boneyard 5.3Ls, slapping on a huge turbo and camshaft and making over 1,000hp, and then racing them a full season! Just think what you could do with 408 cid!

So how big CAN you make one of these suckers? With an aftermarket GM LSX or World Products’ Warhawk tall-deck block plus a 4.250˝-stroke crank the answer is 511cid. But, how big SHOULD you make one of these? According to Horace Mast from Mast Motorsports, who specializes in LS engines, he doesn’t recommend anything larger than a 4.000˝ stroker crank in a stock block with a typical 9.230˝-tall deck due to poor piston stability at the bottom of the bore. The 4.000˝stroke will result in a 408 cid motor with a 4.030˝ bore, and 383 cid with a 3.902˝ bore. Similarly a 4.000˝ arm will provide up to 416 cid for an LS3 and 427 cid in an LS7. He has built LS3 and LS7s with 4.100˝ stroke cranks, but says that they have poor long-term durability, and he doesn’t recommend them, especially for daily driven street cars. Horace limits his tall-deck LSX builds to 454 cid.

A very economical way to build a 408 cid stroker short block is to buy an iron truck 6.0L (LQ9 or LQ4) from a salvage yard for a few hundred bucks and have it bored out to 4.030˝ and install one of the many 4.000˝ stroker crank kits available. You end up with a high compression 408 cid engine that when equipped with a good LS7 head equivalent will produce about 650hp and 550 ft.-lbs. of torque normally aspirated.

If a budget iron truck block is not the approach your customer is looking for, its time to look to aftermarket blocks that when combined with stroker kits can produce stunning results. The following is an updated excerpt from a 2011 Engine Builder article on LS Stroker engines.

The choices for aftermarket LS engines are GM’s iron LSX block, Dart’s LS Next Series, RHS’s LS Race Block and World Products’ LS Warhawk block. Lets look at GM’s LSX engine first introduced by GM Performance Parts at the 2006 SEMA show. The LSX is a cast-iron racing block based on the LS7 engine. It was designed with help from drag racing legend Warren Johnson. It offers displacements ranging from 364 cubic inches to 511 cubic inches (4.25˝ (108 mm) bore x 4.5˝ (114.3 mm) stroke) and is capable of withstanding 2,500 hp. This block incorporates two extra rows of head-bolt holes per bank for increased clamping capacity. The six-bolt steel main caps are the same ones used on the LS7 engine. If you can handle the weight penalty of an iron block over aluminum, the LSX is a good value.

Dart offers several aftermarket aluminum and iron blocks that offer many options such as standard or taller decks, standard or raised cam locations, cylinder barrels extended lower in the crankcase and clearance for a 4.100” stroke crankshaft. Dart also has billet aluminum versions and full-skirted blocks available.

Racing Head Service’s (RHS) LS Race Block is cast out of A357-T6 aluminum with press-in spun cast iron liners that are available in two bore sizes 4.125˝ and 4.165˝. The raised cam position can handle up to a 60mm cam core and a relocated oil galley provides room for a 4.600˝ stroke crankshaft and directs oil to the main bearings first. Two deck heights are available: standard (9.240˝) and a tall version at 9.750˝. The RHS block is chocked full of other features like multiple engine mount options, dry sump connections and access to the two additional head bolt hold downs per cylinder.

World Products’ Warhawk LS Race Block is another max effort block capable of handling huge power numbers. Cast out of 357-T6 aluminum the Warhawk features beefy 1045 steel cross-bolted main caps retained with massive 7/16˝ main studs and cross-bolts. The Warhawk comes in two deck heights – a tall 9.800” and the standard 9.240˝deck. Optional head bolt hold-downs (two per cylinder) help seal combustion pressures on highly boosted engines. Two bore sizes are available – 4.000˝ and 4.125˝ and there is room inside to clear a 4.500” stroke crank. Like the RHS block, the Warhawk has several engine mount locations.

As you can see there is virtually limitless ways to build a large displacement LS engine. And when you consider the plethora of aftermarket cylinder heads, intake systems, and power adders, it makes sense that the LS engine is being stuffed into anything people can get their hands on because the combination of lightweight and big power is too hard to resist. With very little effort you can get old-fashioned, big-block power in a tight, little package.

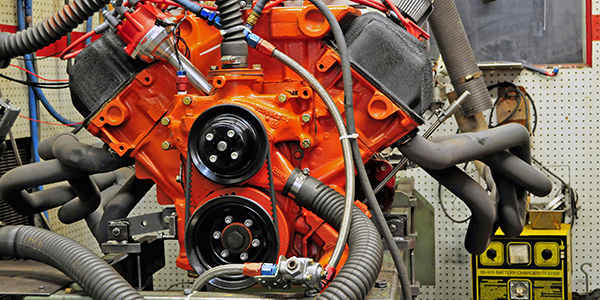

Mopar Gen III Hemi

FCA (formerly Chrysler) has thrown down the gauntlet making its Gen III Hemis the most powerful production cars ever produced with its 707hp Hellcats, 840hp Dodge Challenger SRT Demon and DragPaks models boasting well over 1,000hp in fully-prepped NHRA form – all with less than 400 cid. In fact, the DragPak version is a miniscule 354 cid. How’s this spectacular performance possible? Big, highly efficient superchargers combined with the incredible flow capability and detonation suppression of the Gen III Hemi head design. Drag racers have been exploiting this combination since the Gen I Hemi in the early ‘60s.

This is all good news for those wanting to upgrade the Gen III Hemi with a stroker kit. The Gen III Hemi has excellent-flowing heads and a rugged block design that will easily take a larger rotating assembly with no clearancing or grinding required. Currently, there have been three versions produced by the factory for trucks and passenger cars. The 5.7L, 6.1L and 6.4L are all very similar except for bore and stroke. The 5.7L has a 3.918˝ bore and 3.578˝ stroke; the 6.1L has a 4.055˝ bore and the same 3.578˝ stroke and the 6.4L features a 4.090˝ bore and 3.720˝ stroke. One difference worth noting to those not familiar with this family of engines is that Gen III Hemi cranks have a reluctor wheel that pre-2008 had 32 teeth, and cranks from 2009 and later used a 58-tooth reluctor. To make things a little more complicated 2013 and later Hemis had a unique 58-tooth reluctor compared to earlier models. Take note: nothing will ruin your day more than assembling a customer’s engine with the incorrect reluctor wheel.

Mopar enthusiasts are more closely tied with their brand’s history, so it is no accident that the most popular stroker crank is the 4.050” unit that will make a 392 cid out of a 5.7L and 426cid out of a 6.1L – both iconic Hemi engine sizes. But Gen III Hemi fans are not limited to those strokes. Manufacturers like Molinar Technologies offer cranks in strokes from 3.593˝, 3.795˝, 3.900˝, 4.000˝, 4.050˝, 4.080˝ and 4.250˝. These stroke possibilities and the various bores offer engine sizes all the way to 440 cid (another Chrysler iconic engine size).

Ford Coyote & 4.6L Modular

Of the current production performance engines, the Ford 5.0L Coyote and the numerous versions of the 4.6L Modulars end up being the most difficult and expensive engines to try to enlarge with a stroker kit for a couple of reasons. Like the LS, there is a lack of piston stability at the bottom of the bore with longer stroke cranks. Also, the small-bore cylinder liners are not thick enough to accept any “meaningful” bore. A set of special sleeves will solve both problems to some degree, but the cost/benefit ratio is just not there for most enthusiasts. Several stroker companies like Eagle make stroker kits that with a .030˝ overbore will get you to 5.0L or 305cid. Dedicated shops like Houston Performance can get you to 5.3L (324 cid) with a set of oversize sleeves in your aluminum block. 305 cid-324 cid and it will cost me how much? No matter how you push the calculator buttons, it just doesn’t make sense for a hot street vehicle. If you want or need a big mod motor, the salvage yards are full of iron-block 5.4L engines with 3.55˝ bores and 4.165˝ strokes. The best part is they can be picked up for a couple hundred dollars.

The bottom line is that Ford designed these engines as small-displacement, high RPM engines. They are much better candidates for power adders than stroker kits.

Ford’s 5.0L Coyote is a truly awesome high-performance engine, capable of big power numbers right from the factory. Some see its only shortcoming as its 5.0L size. A couple of years ago, piston maker Wiseco and its development group of K1 Technologies and ERL Performance designed a stroker/sleeve kit that increased the bore to 95mm and the stroke to 4.000˝ for a total of 5.8L or the magic 351 cid size. The K1 H-Beam billet rods are sized so that the ring package is way down on the piston for turbo and supercharged applications, and the generous valve reliefs will accept any cams you want to throw at it. Except for the block sleeving, it is a pretty easy bolt-in installation that should be very durable. While not a budget kit by any measure, dealing with DOHC 4-valve Coyote motors never is.

As you can see, stroker kits are a great idea for some engines and a real headache for others. The trick is to really think through what you are trying to accomplish with your engine build, and not get stuck on any single concept. There’s more than one way to get to the performance level you desire.