Not all engines are created equal – even when they’re using the same basic block. It’s the application that makes the difference, especially when we’re talking about marine instead of automotive. (For this article, we’ll be focusing on inboard and stern-drive engines, as outboards are a separate, small-engine category.)

That’s because both the loading and duty cycle differs, among other aspects. Except under acceleration, an automotive engine might “loaf” along at cruising speeds, revving at 2000 rpm at 70 mph, and using only a fraction of its available power to keep a vehicle moving down the road.

In contrast, a marine engine runs under a constant loading, since it’s encountering much more resistance. It’s propelling a boat either through the water (as in a displacement hull), or on top of the water (running on plane). That means that marine engines run at higher revs for longer periods of time, as high as 4200 rpm almost all the time.

What does that mean for the engine builder servicing the marine market? The valve train is different, for one. It needs to have corrosion-resistant parts (more about that later). And the camshaft profile typically has less overlap in order to prevent drawing in corrosive water from the exhaust.

In addition, the oiling systems need to minimize sloshing due to extra motion from operating on moving surface, from choppy waves and wakes to large, undulating ocean swells. A boat also banks or lists to the side, so all told, the engine operates in a much more dynamic environment. To prevent an inconsistent supply of oil, high-volume pumps are recommended, along with a different type of oil pan.

“Our marine engines require an extra baffling system in the pan to hold the oil in place, so it doesn’t splash away from the pick-up tube,” explains Darren Ragsdale, manager of Jasper’s Marine Engine division.

This company, which offers remanufactured engines (and stern drives too, for that matter), follows a meticulous procedure in cleaning, machining and re-assembling, bringing them back to original spec – or even higher standards. Many of its V8 marine engines also feature a double roller timing chain, align honing, and high-rev lifters. “These lifters are for higher seat pressures, with more tension to get the valve returned,” Ragsdale says.

The harshness of the marine environment is another consideration, especially saltwater. Aims Machine Shop, in Sparks, NV, is experienced in this area, as its restoration of marine engines comprise as much as 50 percent of the company’s workload. While freshwater engines suffer from some pitting in the cylinder walls, “Saltwater engines show a lot more wear,” says Aims’ Antonio Ortega. “There’s a lot more pitting. It just eats everything up.”

To remove deposits from saltwater corrosion, Aims submerges the block in a tank with a special engine-cleaning soap, and also employs acid and bead-blasting. After pressure-testing the cleaned block, the inside is coated with a layer of Glyptal coating. “It seals the rough interior castings of engine blocks to help prevent engine damage and helps to keep oil flowing freely,” he notes.

In some cases, however, it’s not even feasible to remove saltwater corrosion.

“Saltwater corrosion renders most blocks not useable,” Ragsdale says. “They’re beyond repair, and discarded.” Even so, Jasper will still extend a full core credit on these blocks on a like-for-like basis, as long as they do not have visible holes or cracks.

If a shop is handling a rebuild, mechanical cleaning using scrapers, drills and chisels is more typical among marine engine restorers. For hard-to-reach areas, a hole can be cut into the water jacket and later sealed by welding, brazing or epoxy.

The internal passages (water jacket) of cast-iron blocks running in seawater are a particular concern, as this is where must problems occur. That’s why brass freeze plugs are a must in a marine application, along with stainless steel fire rings on the head gasket.

While moisture and oxygen corrode iron, the salt (sodium chloride) within sea water creates a different type of corrosion that is more damaging than the iron rust found on land-based or freshwater iron engines.

Seawater is really hard on anything made of iron. It will corrode as much as five times faster in the ocean environment than in freshwater, and even 10 times faster than air of normal humidity. That’s partly because marine engines may sit for long periods of time with saltwater in their jackets, allowing an electrochemical reaction to take place. Hard deposits can form due to a variety of reasons, including from bacteria and organic matter.

Even after saltwater is removed, and air enters the passages, the corrosion process can continue or even intensify unless an engine builder takes precautions. It’s not uncommon to see a cylinder that looks perfectly okay start to crack or deform after it’s removed from saltwater and allowed to dry in fresh air.

Any successful restoration of a marine engine affected by corrosion requires careful handling and storage of cast parts (isolated from oxygen in a solution of oil or kerosene), along with removing deposits and neutralizing chloride residues. Once any cracks or holes are repaired, anti-corrosion treatments should be applied to restored areas. This treatment would include the exterior as well, which typically gets a tougher grade of acrylic enamel paint with rust inhibitors.

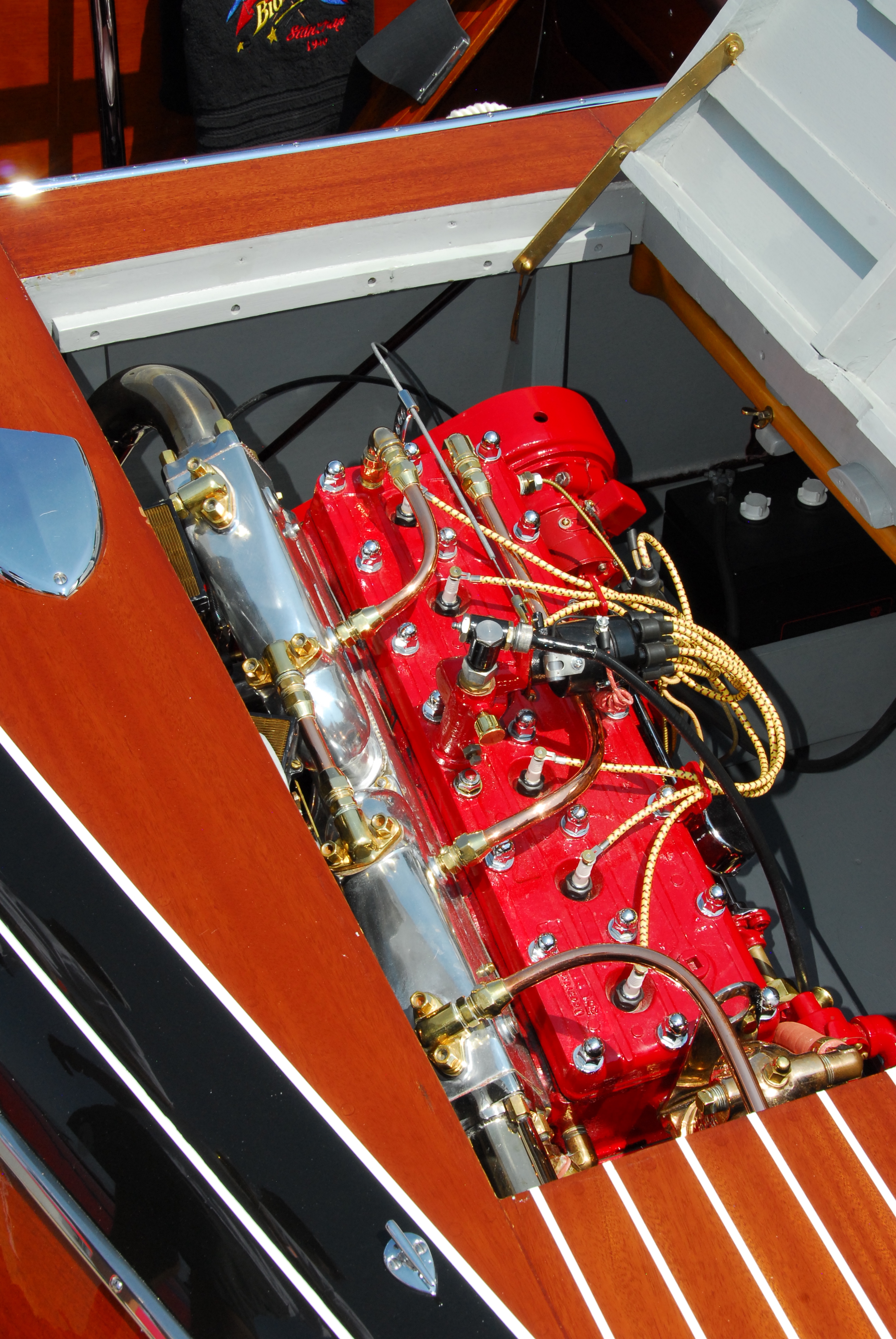

For older engines in a classic boat, there’s another aspect of painting to consider as well. “Color matching of the original engine paint is an important selling point,” Ortega observes. “It’s one of the biggest things we’re known for.” The company has worked on engines dating back to the early 1900s, and is also known for its ability to obtain rare and obscure engine components.

Experienced marine engine builders also know that there’s additional work to be gained in various related components for cooling, mounts, anti-corrosion, electrical wiring, drive unit, fuel system, through-hull fittings, and so forth. The components that reside outside of the core engine are constantly at risk due to the humid (and possibly salty) marine environment. Corrosion is the main culprit here, and the battle against it is constant and never-ending.

In particular, check the exhaust elbow where saltwater leaving the engine block mixes with hot exhaust gases. Stainless steel units are more resistant to rust, but cast-iron manifolds might last only a couple years, depending on the climate and salinity. When an elbow fails, the result can be anything from a messy leak (and more corrosion) to overheating. Prevention requires removing the exhaust hose leading to them and inspecting inside, something worth doing once a year. Engine zincs (sacrificial anodes) also need to be changed regularly.

Another problem area closely involved with engine repairs is the fuel supply. For gasoline engines, ethanol in the fuel can be a serious problem since it absorbs water. When gasoline becomes saturated (which can happen if it sits for a long time), a layer of ethanol and water, known as phase separation, can form in the bottom of the tank. An engine won’t run on the (water-soaked) ethanol solution, and it’s highly corrosive to the system (if it doesn’t have newer, ethanol-resistant components).

Ethanol has also been known to dissolve the resin in older fiberglass fuel tanks as well, which later hardens in the injectors and other components. Bob Rapp of Rapp Marine in Elk Grove, CA says the only remedy in this situation is pumping out the contaminated fuel. But various fuel stabilizers can prevent this phase separation from happening in the first place.

What about newer marine engines? GM’s LS engines are becoming a popular choice for marine applications. Looking at engines on the “crest of the wave,” Katech feels a 700hp Corvette mill is the future of marine propulsion. This naturally-aspirated, aluminum 7.0L LT1 has the power of a big-block V8 (and then some), but weighs less than a cast-iron small block. Katech’s Director of Motorsports Kevin Pranger points to the engine’s improved fuel efficiency from direct injection as well. While all the marine-mandated accessories still need to be developed, the sound (and performance) of a Corvette-powered propulsion has a definite allure.

Taking that approach to its logical extreme is a new V16 engine, a 14.0-liter custom design with LS heads developed by the fittingly named Sixteen Power (more on this engine can be found here – http://bit.ly/2q0iTY8). Katech assisted in its machining and data acquisition, demonstrating a minimum of 1100 horses on tap. “Katech looks to have a bright future working with Sixteen Power on this revolutionary engine.”

The bottom line is that engine builders looking into the marine market need to look behind and ahead to make the most of opportunities. Each has its challenges, but with knowing the unique demands of marine engines makes all the difference for staying on course.