We all get crazy ideas from time to time. Sometimes we see something and that sparks an idea. Other times we’ll have a need and, “necessity being the mother of invention,” we come up with an idea of how to build that special part or tool that would fix the problem. The majority of the time they’re just ideas. But what if you really want that part or that tool, or even that engine?

There are a rare few out there who do not let anything stop them if they believe in their idea. Take Don Groff for example. Don is a car builder who always wanted to take things just a little bit further. Building a custom car with a transplanted engine was just not enough. So with a passion for multi-cylinder European exotic car engines, he decided that his next car project would include that kind of engine. It wasn’t just the initial cost of a good Ferrari or Lamborghini mill that inspired his quest, more the strong desire to “do it all” this time. So he set out on a multi-year adventure to build his own DOHC V12 Toyota, complete with quad turbos and a snake pit exhaust system coming out from the center of the engine. This 5-liter V12 is estimated to make 800 hp.

Starting with two Toyota Supra 1JZ in-line 6-cylinder engines, he proceeded to cut the cylinders off the top of the crankcases. Then he hand-built a new 120-degree “V” lower crankcase from several pieces of steel. The 120-degree Ferrari style design does make for a wider engine, but it also makes for one that will be much easier to balance without large counterweights on the crank, just like said Ferrari. The crankcase was designed to take common 350 Chevy main inserts and a late-Chevy-style, 1-piece rear seal and housing. The semi-finished product is a piece of art, with meticulous welds and rigidity. The Toyota cylinders were then bolted to the crankcase, which was stress relieved and align bored to the Chevy main diameter. It does feature 4-bolt main caps. The oil drain back holes were finished into the new lower crankcase as well.

The custom Scat crankshaft was built with a hub for the Chevy rear seal and bolt pattern for the flywheel. It has the Chevy main journal size and correct spacing and Honda rod journals. The snout was designed to drive the oil pump, dual timing sets and the serpentine belt drive for the dual water pumps and alternator, leaving room for a harmonic balancer. All of this must be taken into consideration when building your own engine design and custom crankshaft.

The Honda-style H-beam connecting rods are longer than the Toyota rods making up for some of the new crankcase height. The pin end was a perfect fit for the OEM-dimension pistons, which were replaced with two sets of forged replacement shelf stock pistons from ICON. The factory dish was maintained to keep the compression ratio right for use with the twin turbos. The pistons were sprayed with an abradable coating by Line-2-Line and will be hand fit to each bore.

To get the desired look, one cylinder head was modified to be reversed on the block. This put all of the exhaust ports to the center of the engine – no small project on its own. Now the camshafts are sticking out of what used to be the back of the head. The cam drive is still by timing belts, which are offset by the stagger of the cylinders and cylinder heads in their typical V-configuration. The belts are kept taut by a new hydraulic tensioner system.

The bottom end is sealed up with a fabricated oil pan of 3/4˝ aluminum with some beautiful details. The oil pump for the dry sump oiling system mounts next to it.

Though there is still a long way to go before this exotic engine will run, one can only marvel at the engineering, planning and fortitude it must’ve taken to hand-build the keystone component of this project, a cylinder block.

The aftermarket is quite saturated these days with aftermarket blocks. All of your popular performance V8s are available in many forms and materials. One must only decide if they want it manufactured in aluminum, cast iron or Compacted Graphite Iron (CGI). Even a few less popular engine blocks like your FE Fords can be had from the aftermarket today. But what if your specialty engine family is not one of these?

Enter Tim Meyer of TMeyer Inc. in Fairmont, MN. Tim specializes in the Ford 335 engine family, Cleveland and the so called “Clevor” performance engines. For those unfamiliar, a Clevor is the slang name given to a Ford Windsor engine fitted with Cleveland style heads. With a background only in automotive machining, Tim has been a driving force in the industry, and you would never know it.

Several years ago, Tim started seeing a need for some specialty tooling to make things operate more smoothly and efficiently throughout his shop. But unlike those who rough together something for a one-time use, Tim had his ideas manufactured and then marketed them through all our familiar tool suppliers.

“Tools designed by machinists for machinists,” was the saying Tim coined for his sideline business. The first mass produced tools were his Pipe Plug Sockets with replaceable steel insert tips. Next came the Harley head plates which were designed to adapt H-D motorcycle heads to your seat and guide machines. One of the last, and a big seller was a Collet chuck for the seat and guide machines.

Tim moved on from that shop and bought his current shop in Fairmont, MN, located near the Iowa border. There is a lot of racing in the central states and he soon found a niche building Ford racing engines. Somewhere along the line he discovered a market in the Ford 351 Cleveland and its siblings – the 351M and 400. Connections were even made with companies in Australia where these Ford engines were much more popular.

Tim has started a line of parts specifically for the Cleveland head engines called “Track Boss.” Some parts he manufactures in his own shop and some parts he contracts out. The biggest product/project requires both.

Early on in the development of Cleveland parts, Tim discovered a need for a variety of pistons. There are stroker combinations and a proper performance piston for the 400 in a flat top and something that had enough compression height to get the compression needed to make some power, just waiting for him to bring to market. His company has sold more than 6,000 of these pistons to date. Now, he has a line of forged pistons made for most Cleveland or Boss applications ranging from 302 to 444 cubic inches.

Once the engines started getting bigger and more powerful, limitations starting cropping up – one weak point being the cylinder block. Todd Buttermore had been working on bringing a high strength, high quality engine block to market for years, but never was able to get it to that point. Tim saw this as the next part of a puzzle that would not only be a perfect fit, but would be the spring board for many more parts and sales.

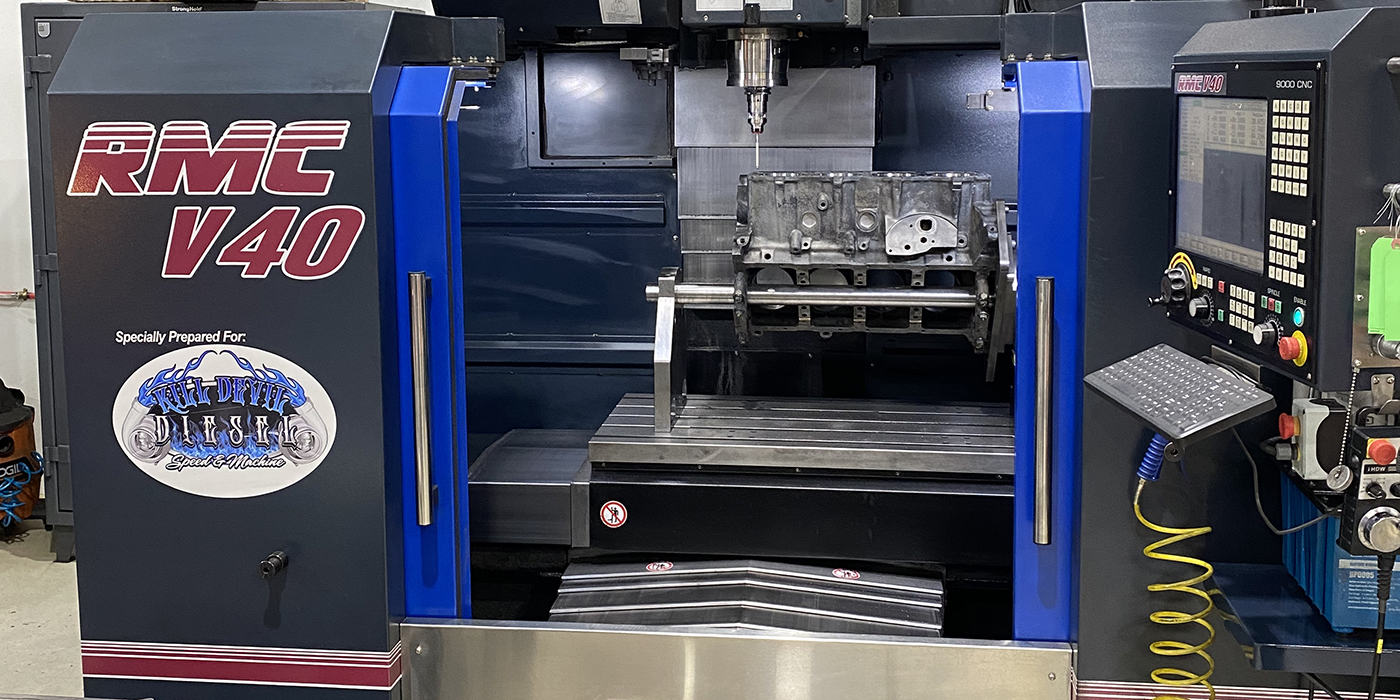

Purchasing the molds and rights to the Cleveland block from Todd was just the beginning. The molds needed some work and a second set with many differences were needed to build in both materials. It took time to develop the right vendors to cast the raw blocks. While they worked through the pours, Tim purchased the CNC equipment needed to finish machining the block castings. Again, another learning process, but this is what it takes to bring something completely new to market.

The blocks will be available in two materials – aluminum and CGI. Good blocks need good strong main caps, so he’s set up to make his own steel, 4-bolt caps, and will be offering these for anyone who wants to upgrade their current block. And if offering steel caps is not enough, Tim plans to market his cylinder sleeves – high strength and low wear.

Tim continues to learn the shortcomings of working with one of the less-popular Ford engines. His block has race-block-style threaded plugs that seal the water jacket holes, instead of your usual freeze out plugs. With no product on the market that exactly fit his needs, he started making these himself.

Another big product project for Track Boss has been their aluminum single plane Boss intake manifold for the 8.200˝ deck small block Clevors. Again, Tim was at the right place at the right time. B & A Intakes was a small manifold company back in the ‘80s. Tim got wind of the opportunity to buy the tooling and the rights to it and the Track Boss name. Tim’s manifold has ports designed for the two-barrel heads and can be ported for a four-barrel size port. Tim also added the injector bungs and the extra Boss 302-style mounting bolt holes. This is another in-house manufactured product, only cast off sight after many hours of cleaning up some pretty rough molds.

Years ago, there was a high flow thermostat available for the Cleveland. These had gone away with Disco globes, but this didn’t stop Tim. Since he found the re-pops to be too fragile and not up to par, he started to search for the originals. Robert Shaw currently owns the company and tooling from the originals, but the tooling needed work. Undaunted, Tim payed to have the tooling repaired and now he’s the sole distributor for these stats, and he has decided that they should be available in three temps, 160, 180 and 195. The originals were only available as 195-degree.

And last but not least, every motor needs some spark, but the offering for good ignition systems for the Cleveland left Tim wanting more. He decided that they needed the old Ford Duraspark, not another H.E.I. for a Ford. So today he’s spinning up his own aluminum bodies in-house and building his own distributors with H.E.I.-style electrical components fitted within. I can guarantee you this won’t be the last product available from Track Boss.

Maybe you don’t see a need to build muscle car parts or anything exotic at all. Out in Carrington, ND there’s still very good business in old tractor engines and the 2-cylinder John Deeres are some of the most popular to restore. However, today it’s getting much more difficult to find parts for these old green beasts. Well, it was before Henry Simons decided to change all that.

Henry is the owner of H & J Machining. Like many in this business, Henry didn’t have an escape plan when the time came to start thinking about leaving the business. If he was going to keep things going, a certain amount of downsizing was to occur and his focus needed to sharpen on particular markets. With a strong customer base in vintage tractors, his biggest concern was the difficulty of finding parts.

Henry had a plan to have valve train for both A and B John Deeres made. After just a few phones calls, he was on his way. Henry trusted from experience that the business would be there, and it was. Within 5 years H & J Machining had valves, guides and valve springs for all John Deere 2-cylinder models.

Things didn’t stop there. Inventory today includes parts for Rumely, Hart Parr, Titan and L Case. H & J also stocks 30 sizes of blank valves with stem diameters ranging from 5/16˝ to 7/8˝. If it’s not in your regular parts catalog or on Henry’s shelf, he can probably make it.

Valves aren’t all they make. They have some large castings poured and they machine some valve guides in-house that aren’t available elsewhere. The Rumely guides they machine are over 7˝ long and are completely machined in-house.

Henry continues to add to their obsolete parts list. Changes in the piston ring market have made it more difficult to find the older, short-run ring sets for some of the antique tractor applications and Henry’s company has addressed this as well with a short offering of piston rings, though none of these are made in-house. They also offer many more small parts that are related to these hard parts.

TMeyer Inc. and H & J Maching are just two examples of businesses who saw a need and took a chance. There are many more small companies making specialty parts for the aftermarket out of their engine rebuilding shops. Yours may be one, or maybe you know of one. This is admirable and a much needed part of our industry.