The School of Automotive Machinists & Technology NHRA Factory Stock Showdown is a lot of words to describe the series that brings COPO Camaros, Dodge Challenger Drag Paks and Ford Cobra Jet Mustangs together to rekindle old drag racing rivalries. It’s good old-fashioned American iron going head-to-head for bragging rights (and prize money too, of course).

The School of Automotive Machinists & Technology NHRA Factory Stock Showdown is a lot of words to describe the series that brings COPO Camaros, Dodge Challenger Drag Paks and Ford Cobra Jet Mustangs together to rekindle old drag racing rivalries. It’s good old-fashioned American iron going head-to-head for bragging rights (and prize money too, of course).

Todd Patterson, a second-generation drag racer and engine builder, says the fact that The Big 3 make competition so accessible is a positive sign for the performance industries.

“First off, the factories – Chevrolet, Ford, and Mopar – have made an effort to try to put performance back into some of what they do, whether it’s a car designed specifically just to go to the racetrack, or whether they simply implement some of that thought into their everyday performance streetcars,” Patterson says. “I think the factories wanted to come up with something that was a little bit more appealing to the masses and get some of their newer engine development stuff out on the drag strips.”

Patterson, president of Augusta, KS-based Patterson Elite Performance, says the National Hot Rod Association (NHRA) and National Muscle Car Association (NMCA) have continued to refine their respective Factory Showdown classes within the grassroots racing arena.

“NHRA expanded the Factory Showdown class to seven events this year. NMCA has six races. There are probably close to a dozen guys who run both because they like to race heads-up,” he says. “You can take your Showdown car and run a divisional race or run one of these other national events that doesn’t have Factory Showdown scheduled at that event, or you can fall back in the Stock Eliminator, but then you’re back to bracket racing.”

The series is reserved for 2008 and newer Camaros, Mustangs and Challengers that meet the COPO, Cobra Jet and Drag Pak designations. The cars must adhere to “stock” type limitations, run heads-up with no breakout, and launch off a .5 Pro Christmas Tree. Although “crossbreeding” of brands isn’t allowed, racers and engine builders are permitted to replace a car’s engine with one of a different year, as long as it meets the sanctioning body’s rules.

Patterson says the NHRA has done a pretty good job to this point on trying to keep them somewhat equal as far as what the potential is of each combination. As a builder of LS engines, he recognizes that the pushrod LS engine is at somewhat of a disadvantage when compared to the Cobra Jets and Hemis. Luckily for him and other engine builders, the rules are liberal enough to allow creativity and innovation to exist, offering the aftermarket the chance to compete with the factories on a level playing field.

Patterson Elite

Nearly 60 years ago, Allan Patterson was an aircraft mechanic by day, grassroots racer by night. Working out of a one-car garage in Wichita, KS he started having success in AHRA drag racing. His success translated to NHRA Super Stock championships, but those victories came at a cost.

“Through that period when he was starting to travel to all these events AND develop engine programs for others while still working at Boeing, he was having trouble using vacation time to go chase points,” Todd Patterson says. “He finally got to a point where he said, I need to do one or the other.’”

In 1979, the Pattersons moved out of the garage/workshop/race shop, into an actual business address in Augusta, KS. “We started building engines there and then shortly thereafter, we added onto the building, added all the latest machine equipment at that time and put in an engine dyno. And it escalated from there,” Patterson says.

Todd started driving in 1983 and had success of his own in Competition Eliminator, Pro Stock and Pro Stock Truck. Eventually, he says, family came first for him as well and he settled into coaching his kids and helping other race teams succeed.

In 2015, Patterson Racing merged with Elite Motorsports in Wynnewood, OK to form Patterson Elite. The merger has allowed Elite to maximize its efforts to provide the engines for Pro Stock driver Erica Enders and others, while Patterson has been able to incorporate even more professional-level technology into its already successful Sportsman racing program. Patterson supplies David Rampy, the winningest Comp Eliminator driver of all time, as well as other less known but equally ambitious drivers.

“We got in on the ground floor of Factory Stock in 2012,” Patterson says, “racing a 427 normally aspirated version. A guy named Bob Tyler, 30 miles south of us, owned a company called Husky Floor Liners. And he’s a big car collector guy who was at the SEMA show for his company, when he passed the Chevy display. He saw the COPO Camaro, and he decided right then that he wanted to buy one. The guy told him that in order to get one of the 69 produced he’d have to get on a waiting list.”

Patterson says the Chevy rep was adamant that they didn’t want car collector guys buying these cars and just putting them away and not racing them. “They told him, ‘We want to get out and race against the Fords and the Mopars and create a new generation of Chevrolet race cars,’” he explains.

After hearing that having an active NHRA driver’s license would help his cause, Tyler called the Pattersons and asked if they would drive the car.

“My dad is a car collector too, so Tyler came in to shoot the breeze about it. I had to explain, ‘Look Bob, I already have a Comp Eliminator car here that goes in the 7s – it’s a pretty good ride and I’ve had some success with it. I’m sure your 9-second COPO Camaro is going to be a hot deal, and everybody’s going to pay attention to it – but really, what’s in it for us?’”

Patterson says he realized the program could potentially open up a new market for his team’s engine building perspective and agreed to race the car if Tyler bought an engine first.

“We started getting people who would call and say, ‘I want one just like it!’” Patterson says. “Guys would ask how much it would be to do the engine, but when I’d give them an estimate they’d admit they didn’t know anyone they could trust to pull the engine and hook it all back up correctly. So after taking a few of these calls I started to worry, how am I going to get these guys in the door if I can’t even get them to take their engines out?”

Patterson expanded his shop’s capabilities in order to accommodate the customer who wants to drive the car, not necessarily work on it. “I have a couple guys who do a lot of the R & R work who came right from a dealership,” he says. “These are normal, flat-rate guys who aren’t scared of wiring looms and things that the average engine builder might be unfamiliar with. I’ve told customers, just get the car to us – we’ll do the work.”

Patterson says, “As time has evolved, we’ve figured out that being able to do more than just engine work has really helped drive the engine part of it.”

Patterson explains that his engine-building program starts with blueprinting an engine to Factory Showdown specs.

“With the design of the LS being completely different from the original first generation small block design, it was definitely somewhat of an initial learning curve, because you’re going from carbureted engines over to electronic fuel injection. It definitely opened up some different ideas that we had to concentrate on to be able to make the kind of horsepower we needed just because of the electronics.

Building the Perfect Beast

Patterson says despite its name, Factory Stock actually offers a great deal of opportunity to the independent engine builder.

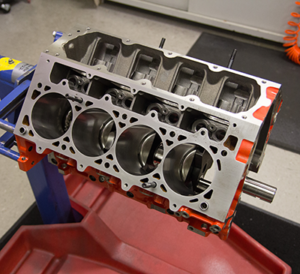

“If you want to you can build your own car and clone it as long as you’re within the set of rules that they allow for the chassis. There’s no rule that says you have to have a COPO or they’re not going to let you race in Factory Showdown,” he explains. “We’re actually dealing with a LSX high-performance Chevy block that comes in the car or that’s what you would start with if you were to build one from scratch.”

Patterson says this engine design is based off of a 4.065˝ bore, 3.370˝ stroke, 6.350˝ rod, eight cylinder engine. Any factory OEM or sanctioning body approved direct replacement engine block is permitted. Maximum cylinder bore over stock is .080˝. Bores will be measured at the top of the cylinder where ring wear is not evident. Cylinder blocks may be sleeved.

“We’re going to bore the block out, typically .070˝ over. This gives us .010˝ to play with, so we’ve got a number of rebuilds if you got a nice straight cylinder wall and the block season comes back in, you might take a half-thou out of the material to get it to spec straight and to get your XYZ numbers for the cross hatch,” he says.

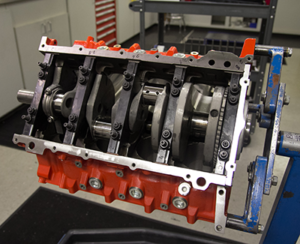

Crankshaft rules allow for aftermarket cranks as long as they maintain OEM configurations (i.e., billets, knife edging, etc. prohibited). Stroke tolerance is +/- .015˝. Lightening of the crankshaft (other than normal balancing) is prohibited.

“We’ve seen a change from a six counterweight, 4340 crankshaft. Due to the output of these engines, a lot of people were either encountering some problems or could tell just on tear down that on the center three main bearing journals, the bearing was wearing excessively towards the outer edges instead of a nice wear pattern across it. That is an indication that there’s flexing going on, and that it’s going to cause failure at some point,” Patterson explains. “In the past two seasons, ’17 and ’18, they did implement an eight counterweight LS crankshaft that everybody is allowed to use now in this build. We can run a coated bearing, but we’re not allowed to alter the rod or main journal sizes. You can’t go with a smaller journal and put a spacer bearing in it, or go to a smaller journaled rod, which would slow down bearing speed; that is pretty common in a Pro Stock motor or Competition Eliminator motor.”

Patterson runs a Callies crank and steel Callies 6.350˝ Ultra connecting rods. “We’re allowed a .015˝ leeway on the rods, so the maximum stroke that we can run in this Chevy engine is 3.385˝. In a lot of cases, guys will just stay to the shy side of that and make it .013˝ longer,” Patterson says. “That way you’re not putting yourself on the line – you know, our stroke checker in our shop said it was .015˝ long, but NHRA’s instruments may be a little different than yours and they read that you’re .016˝ or .017˝ long.”

Stock or NMCA accepted aftermarket connecting rods are permitted. Length must be stock +/- .025˝ center to center. Rules state that the combined weight of the piston, pin, rings and connecting rods must be equal to or greater than the NHRA stock replacement minimum assembly weight.

Approved stock or aftermarket pistons and pins are permitted but must remain dimensionally unaltered. Aftermarket pistons may be forged or cast but must be the same overall design with the same dome and/or dish configuration as the factory OEM piston.

“It comes down to whatever you feel is best suited for your combination and then you’re allowed an aftermarket piston, but it must be an approved piston that is listed in the accepted products list. We are allowed coatings, and we use a custom skirt coating formulated to withstand extreme temperatures with excellent adhesion even after repeated thermal cycling,” Patterson says.

“In addition, we incorporate a custom piston dome coating; a high-temperature ceramic coating designed to protect the piston dome in high-temperature applications. The coating creates a thermal barrier that is both durable and resistant to thermal shock when applied to the top of the piston. It is designed to reflect heat back into the combustion chamber, increasing exhaust gas velocity and greatly improving scavenging potential,” he says. “The barrier inhibits heat from being conducted through the piston to the wrist pins and rods, which will in-turn keep the crankshaft, bearings, oil and entire bottom end at a lower temperature.”

The whole key, Patterson says, is to see who can make the best sealing short block, the best slipping piston. “You’re not allowed to alter the ring groove width or the width of the ring, but it doesn’t say what kind of ring you can run. We’re running diamond-finish rings, just like a Comp Eliminator or today’s Pro Stock Motors would run. It’s a super-flat ring and super accurate. With the skirt coating on the pistons we can run a little bit tighter in the bore – by doing that, we’re keeping the piston straighter in the bore throughout the course of the ring travel, so it’s less apt to be flopping in the bores and collapsing the skirts and possibly breaking the ring seal.”

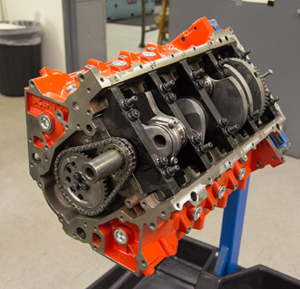

Race rules say aftermarket timing covers are permitted as long as factory OEM-type timing gears and chains are used. Aftermarket gear drives and/or belts are prohibited.

“We can run any aftermarket camshaft as long as it’s within what the stock journal of the cam, or the cam tunnel was when the specs were presented to NHRA. In our case, it’s a 55-millimeter diameter cam that comes in a LS block. It can have a custom grind, and we favor Bullet Racing cams out of the Memphis area,” he explains.

Cylinder head rules are strict. All cylinder heads must be unmodified and meet all dimensions for year, make and model being claimed. This includes intake port runners, exhaust port runners and combustion chambers. Regardless of poured volumes any modifications to the cylinder heads are strictly prohibited.

“The cylinder heads on the COPO-Factory Stock Showdown engine comes from Chevrolet as a CNC-ported LSX/LS7 style head, which means that the valvetrain area is just like a conventional LS7 head with pedestal-style rockers. The stock ratio was 1.8:1. Last year, mid-season, they allowed us to go to a 1.9:1 ratio, which helped increase our overall lift and created some stability to where guys weren’t having rockers fly off and push rods fly out because they were over-running an OE part that really wasn’t designed to do what we were asking,” Patterson says.

Aftermarket or factory lifters are permitted so Patterson runs a Jesel tie bar LS lifter. “We’re allowed any push rod thickness so we can maximize the wall thicknesses and diameters. Since we’re trying to achieve .676˝ max lift, we’re not losing 10 or 20 degrees because of deflection in the push rod area. And then we upgrade the valve train with PAC valve springs, retainers, locks to suit our cam designs.”

He says there are really two choices: builders can send the heads out to have a valvetrain expert machine the rocker pads down to a blueprint and re-drill, tap and put inserts in the valve or the rocker stand bosses and mount a Jesel shaft rocker to it.

“You’ve now got a real roller-tipped, normal, regular rocker-style assembly versus an individual pedestal style, non-roller tip rocker,” he says.

Or you can do the work in-house. They’ll provide you with a blueprint for the shop with the equipment and the know-how.

“The cylinder head comes with a titanium intake valve already and we’re not allowed to increase the valve sizes or change the valve seat angles. For the most part, everybody runs the titanium valve that’s either supplied with the head or you can buy them right over the counter at your Chevy dealer,” Patterson says. “The exhaust is a 1610 sodium-filled, which is probably the weak link of the two. And due to the fact that these are boosted engines and you get a lot of exhaust temperature, the cycle expectancy of the exhaust versus the intake is probably a quarter.”

Patterson says these engines are 40- to 50-run engines before they’re due for a rebuild and he believes it’s a good idea to cycle the valves out at least every other rebuild.

A lot of these rules are based off of the way things were written long ago for Stock Eliminator, Patterson says, and some of it still applies. “They’ve made some changes as the years have gone by, but they specifically say you cannot O-ring the blocks or the head surface,” he says. “We run a three-layer MLS head gasket that is specific to the bore of the engine. About the only thing we can alter is go with a thicker or a thinner gasket depending on where our parts stack up.”

Intake manifolds must be the factory OEM manifold for the year, make and model of engine claimed. Any alterations and/or modifications to the intake manifold are prohibited.

Whipple 2.9L or 2.3L Eaton TVS are the only superchargers permitted. Throttle bodies must remain in the stock location for year, make and model of engine being claimed. Modifying the supercharger is prohibited. The 2.9L Whipple supercharger rotors can be no more than 268 millimeters (10.55˝) in length and no larger in diameter than 104.4 millimeters (4.110˝).

“The lower pulley is an 8˝ pulley and they have reduced the size of the pulley at the blower from 3-3/8˝ (produced in ’16 and ’17) down to a 3.250˝. And then last year about mid-season, they allowed us to go to a 3.125˝. Basically what that’s doing is spinning the blower faster, increasing the boost that it can generate with that pulley combination. Ultimately that increases horsepower.”

Patterson says the oiling system is one area in particular that has shown room for improvement. Although oil pump location, oil pump drive and the complete oiling system must remain as originally produced – any oil pan is permitted, a stock or aftermarket OEM-type oil pump is permitted and the use of an accumulator is permitted.

“You do have to run the stock oiling system but we’re allowed to modify it. The oil pump runs one-to-one off the crank so it’s spinning super fast. I don’t think anybody within the OE division of Chevrolet was worried about somebody turning this into a racing application at the time that it was designed. We’re probably running 2,000 RPM higher than what they ever conceived it would. We have found a little bit of horsepower working with the guys at Melling,” Patterson understates.

He admits that the partnership with Melling on Erica Enders’ Pro Stock car gives him a leg up on oil pump development. “A lot of guys encountered a lot of bottom end failures because of cavitation, because the oil pump was spinning so fast that it would air lock or try to cavitate. Then you would have a lack of flow to your mains and into the rods. So you’re spinning bearings and spitting rods out of the crank. We’ve actually been able to work with decreasing pressure and increasing volume.”

Patterson says despite strict rules that make much of his professional experience overkill at the Factory Stock level, much of his success comes from simply paying attention to detail and being consistent with the build. “You use good parts and you put them together right and hopefully, you’ll get the wins.” ν