The ARMEX Difference

Non-destructive baking soda abrasives can clump when wet, but ARMEX has a solution. See why its MoistureGuard is an advanced flow aid for your abrasive.

Video: The Advantages of ARMEX

If you consider non-destruction cleaning critical to your shop’s daily routine, ARMEX offers numerous advantages such as not damaging parts and moisture resistance. See how it could help your shop.

Video: ARMEX MoistureGuard8

Non-destructive, baking soda abrasives can clump when wet, but ARMEX has a solution. See why its MoistureGuard is an advanced flow aid for your abrasive.

Video: ARMEX in Action

Clean engine parts quickly and easily with ARMEX baking soda without damaging the part. Watch just how easy it is.

Video: Cleaning with ARMEX

ARMEX soda blasting can clean contaminants off of any size part without damage to the part surface. See why it may be a solution for your shop.

ARMEX Launches Re-Man XL Abrasive Blast Media

ARMEX, a global brand of Sodium Bicarbonate (baking soda) abrasive blast media, has announced the launch of Re-Man XL at the Big R / Automechanika in Atlanta.

ARMEX Launches Social Media Networks

ARMEX, a global brand of baking soda used for non-destructive abrasive blasting has launched social media networks on Facebook, Instagram, Twitter and LinkedIn.

ARMEX (Episode 3) – PRI 2016

Brian Waple of ARMEX provides a firsthand look inside a blast cabinet as baking soda is used to clean an engine part.

ARMEX (Episode 2) – PRI 2016

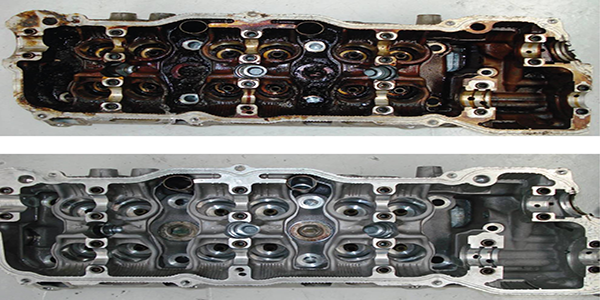

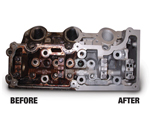

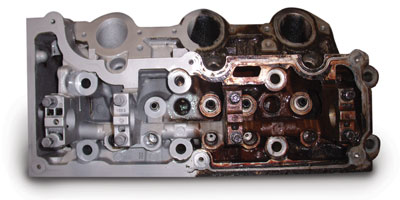

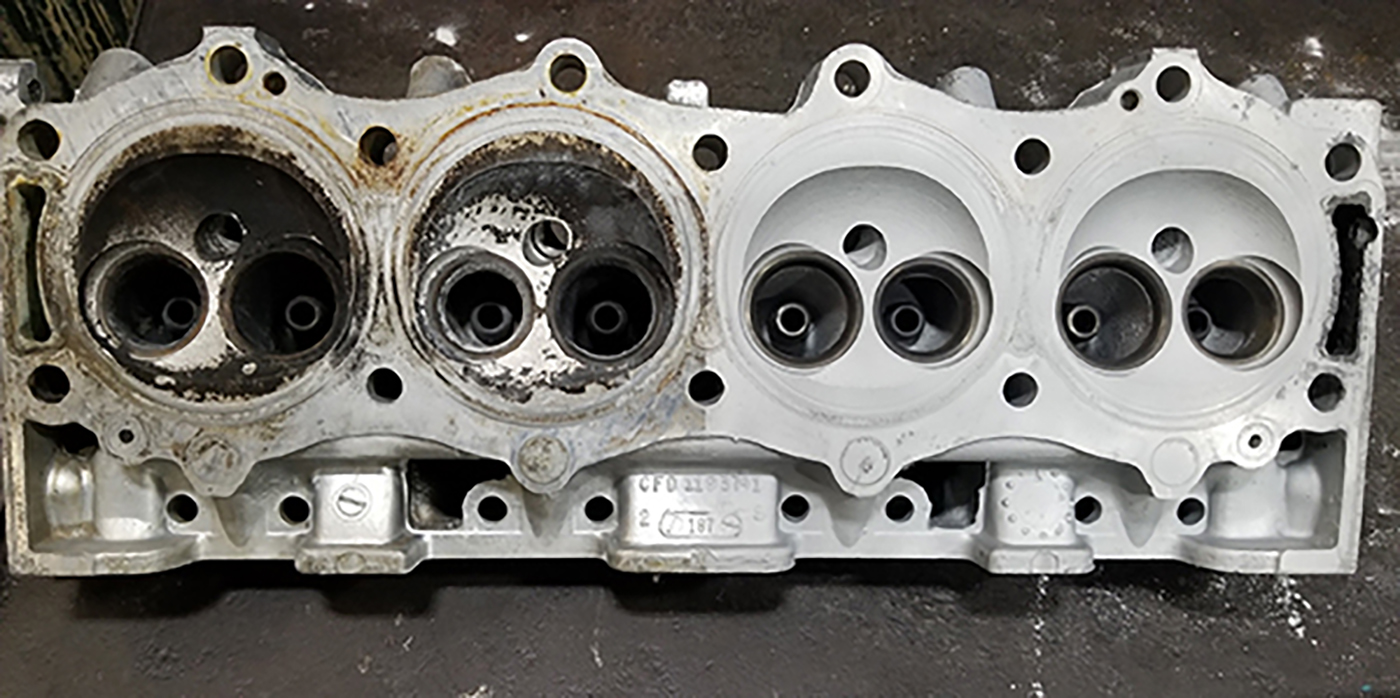

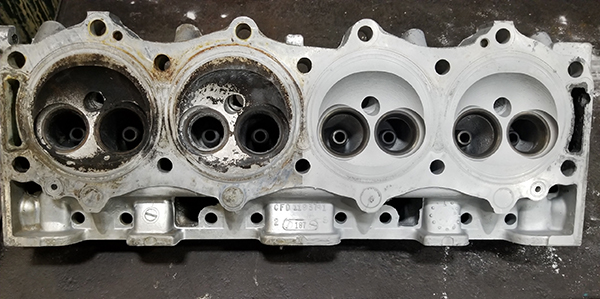

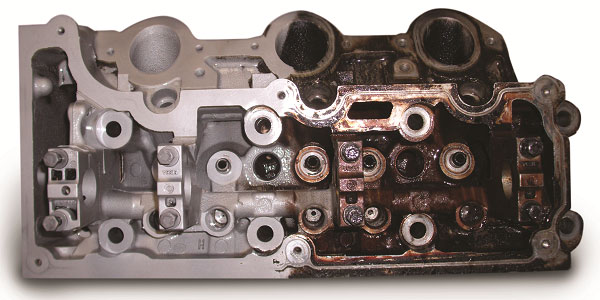

Brian Waple of ARMEX shows how baking soda can clean engine parts of oils, grease, paints, burnt on carbon and other contaminants with before and after demonstrations.

ARMEX (Episode 1) – PRI 2016

Brian Waple of ARMEX talks about the advantages of using baking soda for dry blast cleaning and non-destructive cleaning on engine parts.

Is Non-Destructive Cleaning Critical? ARMEX is the Only Choice

When part specifications and surface tolerances cannot change, the only blasting abrasive to use is ARMEX. The gentle physical propriety of baking soda, yet aggressive cleaning ability is what makes ARMEX the only choice.

All Things Media Blasting

Engine building is a segment of the automotive industry that has always been ahead of the curve in media blasting, and no matter the engine shop, cleaning equipment is a common bond.

Soda Blasting to Clean Engines and Parts

Baking soda will safely clean many different types of material including steel, lead, aluminum, plastic, rubber, alloys, masonry, stone, concrete, composites, and more without damaging them.

Got Grease! Baking Soda Cuts Grease… and Time

Cleaning is being done every day and is an integral part of many businesses and their processes. One of the most commonly asked questions about using sodium bicarbonate (a.k.a. baking soda) as a blasting abrasive is simply: How does it work? Let’s start with: What is abrasive blasting? Abrasive blasting uses either pressurized air or

Video: Baking Soda and Non-Destructive Cleaning

The reasons you should consider baking soda when you clean.

Improve your Turbocharger Cleaning Process with Soda Blasting

It’s been more than 100 years since the idea for a turbocharged engine was developed. Originally their use had been limited to very large diesel engines and while there have been additional innovations for use in automobiles, it was not always the most popular power adder. The boost was powerful but the cost was too

Cleaning Components with Baking Soda

There are many different processes for cleaning parts and components before engines can be rebuilt, and engine builders use a variety of cleaning solutions for different reasons. However, the argument can be made that sodium bicarbonate blasting or soda blasting has numerous advantages.

Sodium Bicarbonate – A User-Friendly Blasting Abrasive

Sodium bicarbonate blasting or soda blasting, is a user-friendly process for the removal of grease, oil, burnt carbon and many other contaminates experienced in engine building. There are many different processes for cleaning parts and components before engines can be rebuilt, however they are not all equal.

Engine Part Cleaning Tips and Techniques

It’s not fun, but vital to successful rebuilds According to a recent Engine Builder Machine Shop Market Profile, in which we survey hundreds of machine shops across the country, about 15 percent of the total production time for rebuilding an engine is spent in the cleaning process. While our wives may not agree that we