Machining a Cylinder Head for Valve Seats – Part 1

Steve Morris Engines recently finished machining a new SMX cylinder head, and now it’s time to machine in new valve seats. Watch as Steve walks through the whole process of cutting a new seat and fitting it into the head!

Rottler’s SG10XY Cylinder Head Machining Center

Combined with the lightweight air float workhead, the SG10XY gives perfect centering in the valve guide and excellent concentricity.

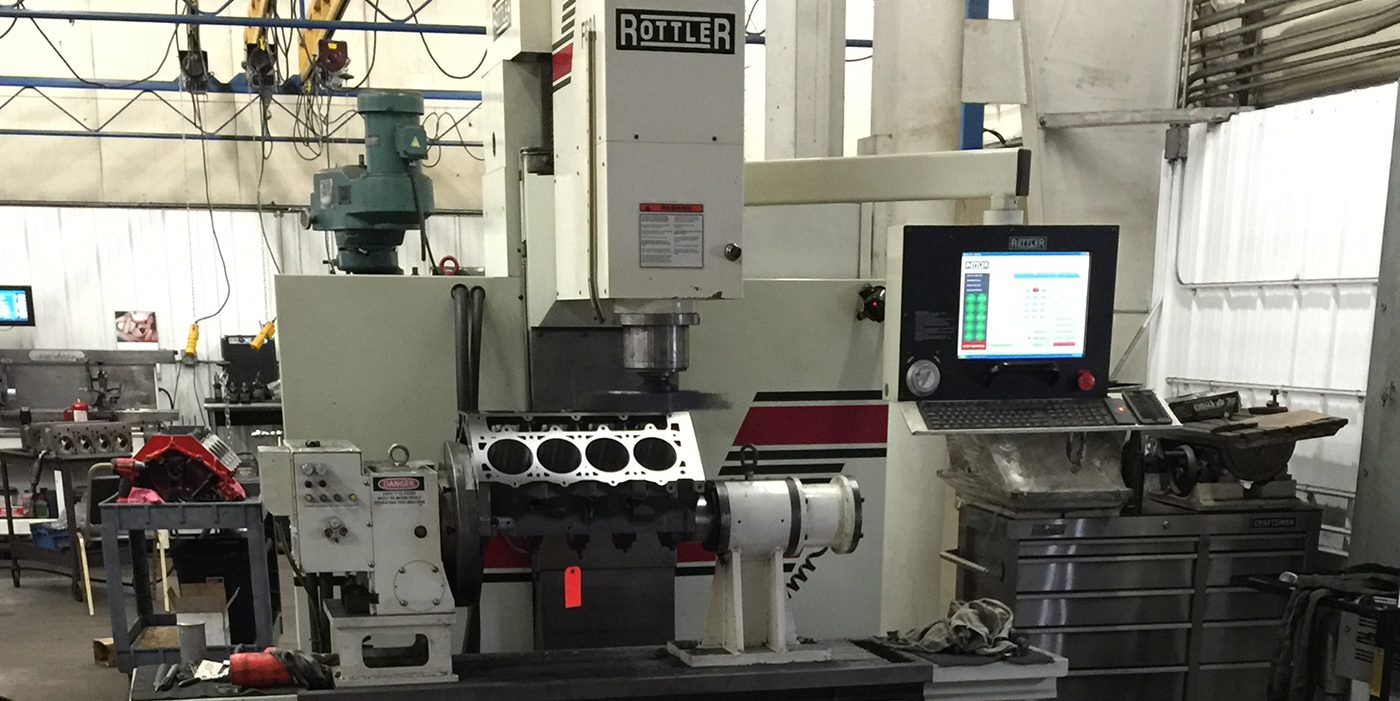

Block Machining with Rottler’s F69A Pt. 2

Steve and the guys previously walked through decking and boring a block on the new Rottler F69A machining center. Now, they walk through lifter bores and receiver grooves.

Block Machining with a Rottler F69A

Steve Morris has his new Rottler F69A running, and the guys are getting training on the new machine. As such, they walk you through how the Rottler F69A decks and bores with ease.

Rottler EM79 Machining Center

These versatile machines are able to perform common jobs such as boring/sleeving, surfacing (heads and blocks), main and camshaft line boring, and general industrial CNC machining.

Rottler’s 5-Axis EM69HP Universal Machining Center

Rottler’s next generation 5-axis CNC multi-purpose machining center offers the precision and speed needed to reproduce cylinder heads with exceptional accuracy.

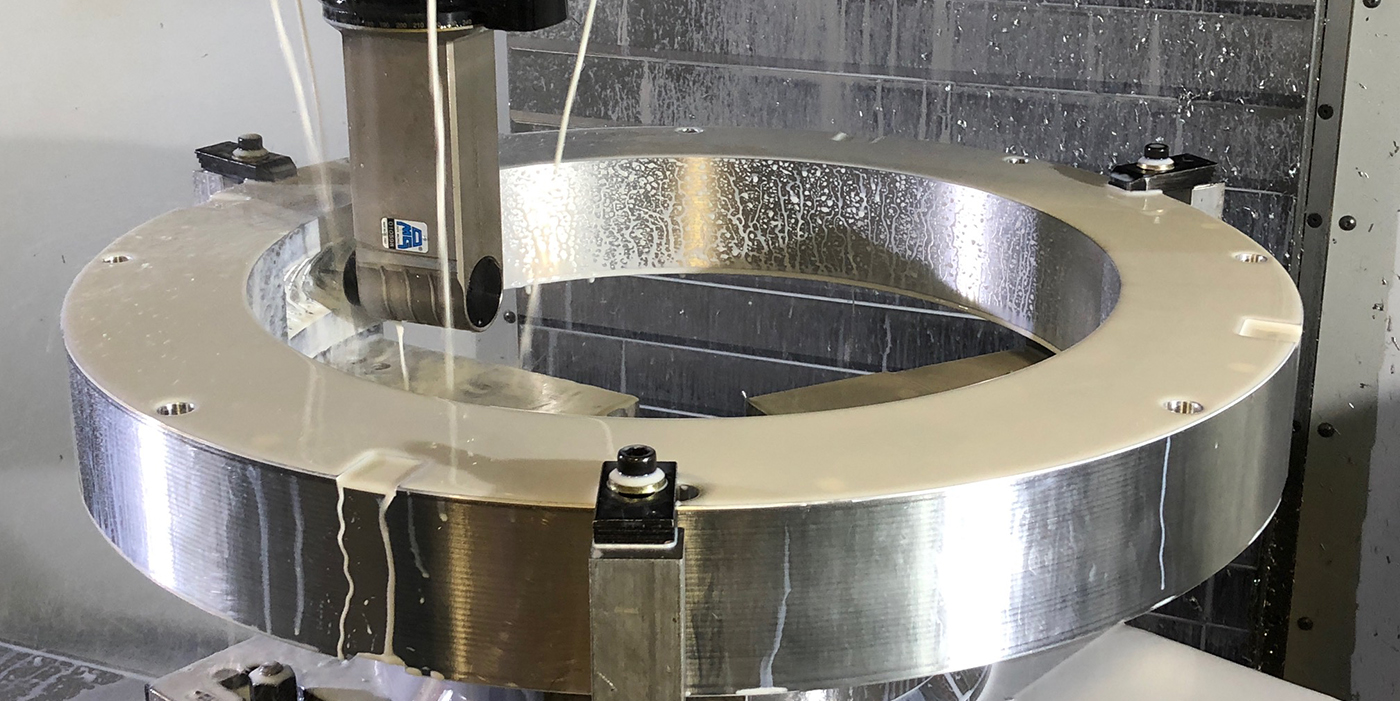

Machining Steve Morris’ SML Heads – Part 2

Now that Steve has everything setup in the 5-axis Centroid CNC, the real machine work has begun. Check out the progress on these billet aluminum heads.

Romi D 1000 Vertical Machining Center

This Romi Machining Center is equipped with a low maintenance, 40 big plus taper direct drive motor that improves stiffness, accuracy and allows increased depth of cut.

GROB Systems’ Second Gen G350 5-Axis Universal Machining Center

The machine’s unique axis arrangement permits upside down machining, offering almost limitless possibilities for part machining.

GROB Systems G750 5-Axis Universal Machining Center

The G750’s unique machine concept includes a horizontal spindle position that permits the longest possible Z-travel path and optimum chip fall. The arrangement of the three linear axes offers maximum stability by minimizing the distance between the guides and the machining point.

GROB Systems’ G550 5-Axis Universal Machining Center

The G550 is controlled by the powerful GROB4Pilot machine control panel, which offers a multi-functional user interface that provides machine operators with a convenient working environment.

Romi DCM 620-5X Hybrid Vertical Machining Center

The DCM 620-5X Hybrid is one of Romi’s complete line of hybrid manufacturing machine tools that combine traditional machining operations with 3D metallic additive manufacturing.

Metalworking Fluids and Machining Webinar

Join PERA for a webinar on Wednesday, February 17, 2021 at 10:00 AM CST with Ed Jones and Mike Ditzel of Hangsterfer’s Metalworking Lubricants. Ed Jones, technical director of Hangsterfer’s Metalworking Lubricants will discuss what makes metalworking fluids environmentally friendly and how they are sometimes simple and sometimes very complex formulas and technology. These technologies will

Buying Machining Equipment

With the cost of some of these pieces of equipment equaling that of a house, it is crucial that engine builders and machine shop owners understand what options are available to them when looking to purchase new or used equipment.

Machining Powdered Metal Valve Seats Webinar

Join PERA and Dura-Bond for a webinar on Wednesday, August 19, 2020 at 10:00 AM CDT all about machining powdered metal valve seats. Powdered metal valve seats can be difficult to machine. Charles Barnett, president of Dura-Bond Bearing Company and Chuck Lynch, director of technical services for AERA explain why this material has become the material

Machining for Other Industries

Modern CNC equipment and machining systems are capable of doing work on anything you can run a program for. Some shops have started to find additional uses for these machines.

Methods 5-Axis Bridge-Type Machining Center

Each machine is made to Methods’ design and engineering standards and is fully backed by Methods industry-leading service and support.

Methods Machine Tools’ Nakamura-Tome MX-100 Multitasking Machining Center

The new multitasking turning center is equipped with a powerful 15 HP upper tool spindle with 20,000 rpm and turning capability. A 8,000 rpm milling turret offers 12 tool stations with 24 indexing positions.

Methods Machine Tools Vertical Machining Centers

Methods Machine Tools, Inc., a supplier of precision machine tools and automation, has introduced a new line of Methods Branded 3-Axis Vertical and 5-Axis Bridge Type Machining Centers.

CNC Machining Equipment

What’s Keeping You From Making the Plunge? I’ve discovered when I talk with Engine Builder readers about CNC equipment the conversation often falls one of two ways: it’s either the best idea in the history of the industry or it’s just too expensive, too complex or just too different. In conversations with equipment suppliers, on