November 2016 Shop Solutions

GREASY HANDS LOSE GRIP When my hands are a little greasy, I have a hard time turning and gripping the twist knob to send my centering fingers out on my Kwik Way Boring Bar to contact the cylinders firmly. My fix was to cut a 2- inch long piece of a used bicycle inner tube

October 2016 Shop Solutions

BIG D HEAD HANDLE Diesel cylinder heads are heavy and can be dangerous to move around. I use a rocker arm shaft and bolts from a Detroit to make a handle for carrying Detroit heads around the shop. It helps keep my fingers in working condition and keeps the head in good shape as well.

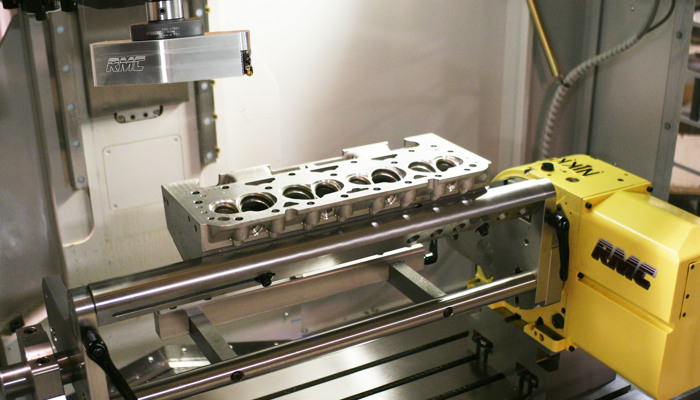

Head and Block Resurfacing Equipment

Regardless of what type of engine work you do in your shop (stock, performance, diesel, marine or anything that comes in the door), you need the ability to surface heads and blocks. Deck surfaces on high mileage heads and blocks are often corroded, pitted, scratched and/or out-of-flat – especially if the engine blew a head gasket or overheated.

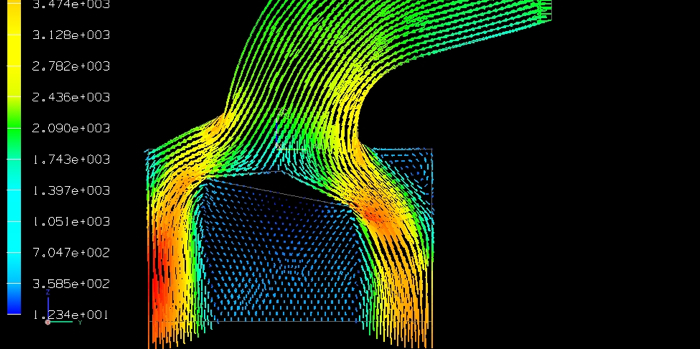

Flow Bench Testing Is More Than CFM Numbers

On the surface, flow bench testing seems easy, but it’s not. Many in the industry have become solely fixated on cubic feet per minute (cfm) numbers, placing importance on a number that is easily manipulated and ignoring other data about a cylinder head’s performance. This thinking would make flow bench testing seem easy, but this thinking is wrong and won’t do you any favors come race day.

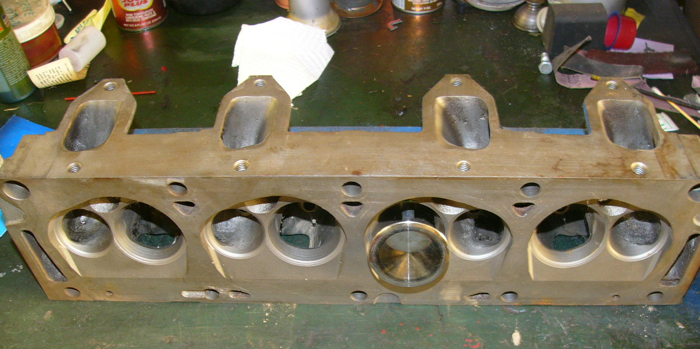

Lost Art of Head Porting

If I had my current shop rate paid to me in a lump sum for every hour I spent porting and flowing heads and intakes in the ’70s and ’80s, I could build a new race car. In ’76 when I started running Pro Stock, my wife Linda got me a SuperFlow 110 for Christmas so I could flow my own heads.

Shop Solutions September 2016

I make my own large threaded repair bushing from tapered pipe thread oil galley plugs, with an internal hex. The material of these plugs is hard enough to tap clean threads into, and very similar to your cast iron block or head.

Shop Solutions August 2016

The old adage, “Time is money” has never been more true than it is today. With the high costs of labor, doing a job quickly and efficiently can be the difference in making money or losing it.

Shop Solutions July 2016

Sometimes machine shops are called on to solve more than engine issues. Toyota rear axles are difficult to disassemble and usually require replacing the reluctor gear when replacing the bearings. I made a jig to drive the axle out of the housing using my press.

Shop Solutions June 2016

We live in a time where aluminum blocks with cast-in sleeves are common and we still need to remember to account for how different metals behave. We build several dozen Gen III and Gen IV GM LS type motors per year. We finish our cylinders .001” tighter on the aluminum block engines to compensate for the additional growth when the block gets up to operating temperature.

Rebuilders Choice

Packard Industries

The SCAT Story

SCAT was born in 1962, created by Tom Lieb who ran an auto parts business out of his parents’ garage while still in college.

Help this Industry – and Help Yourself, Too

As a reader of Engine Builder, you’ve no doubt become aware of the Performance Engine Builder of The Year Contest over the past four years. You’ve read stories of our winners and runners up and perhaps thought, “Heck, I could do that.” Yes. Yes, you can. And you should.