Comec RP1400CNC Resurfacer

The RP1400CNC resurfacer construction technology combines highly innovative solutions with tested technologies, like the linear guides and recirculating-ball feed screws.

Block Machining with a Rottler F69A

Steve Morris has his new Rottler F69A running, and the guys are getting training on the new machine. As such, they walk you through how the Rottler F69A decks and bores with ease.

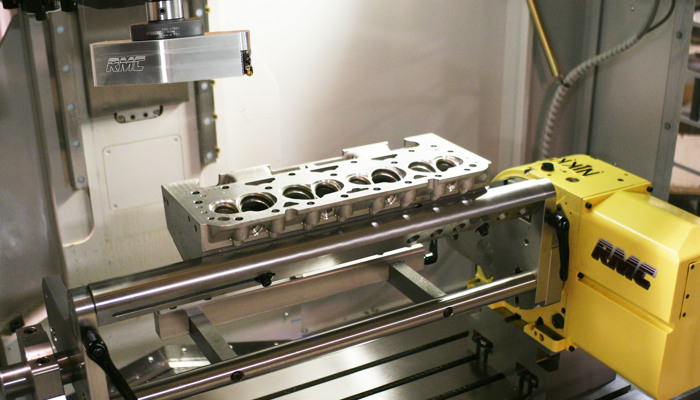

Rottler’s EM45 CNC Machine

The EM45 features universal CNC technology designed for all engine shops and allows you to probe, surface and bore on the same machine.

Comec ACF200 CNC Boring Mill

Comec’s ACF200 CNC cylinder boring/resurfacing machine introduces highly innovative solutions, making this machine faster and more practical to use.

Goodson High Performance Resurfacing Spray

HPS-16 gives you more performance from your PCD inserts and prolongs the life of your cutters.

Joe Baker’s Kras KR1000

KR1000 surfacer is a perfect fit for the automotive machine shop and the KR1500 surfacer for the diesel shop.

Ultra-Smooth Surface Finishes

Determining the correct surface finish means you must consider the metallurgy of the head and block castings along with the type of head gasket you use.

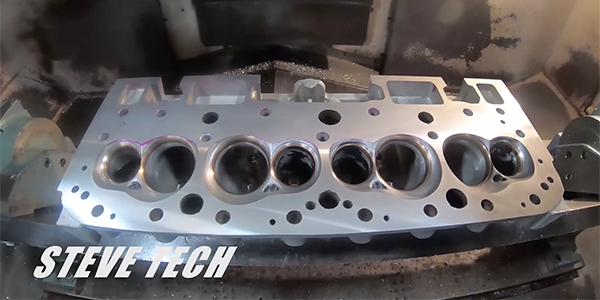

Resurfacing Cylinder Heads

If your cylinder heads don’t have a perfectly flat, shiny surface, they’re not done right and you’ll need to do those again. Steve Morris explains why a correct surface finish is so crucial.

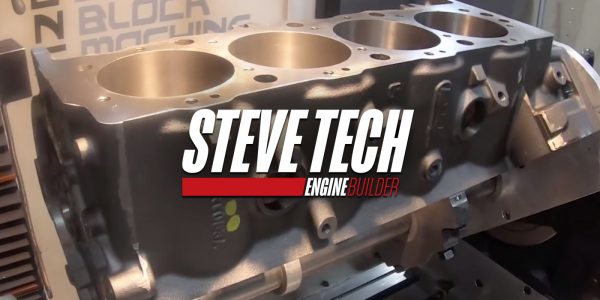

The Importance of Block Resurfacing

Resurfacing the decks on blocks and heads is vital to getting high performance out of your engine.

Head and Block Resurfacing Equipment

Regardless of what type of engine work you do in your shop (stock, performance, diesel, marine or anything that comes in the door), you need the ability to surface heads and blocks. Deck surfaces on high mileage heads and blocks are often corroded, pitted, scratched and/or out-of-flat – especially if the engine blew a head gasket or overheated.