Since you all indulged me last month with editorial musings, this

Since you all indulged me last month with editorial musings, this

month will be a couple of Practical Builder Tips (PBTs) that should

keep you out of hot water from time to time. They’re somewhat generic

but have been popping their ugly heads in all types of engines and they

have no manufacturer preference so no one is immune.

First are tubular camshafts. They are light and hollow, they

First are tubular camshafts. They are light and hollow, they

have cam lobes positioned on a spline and then the tubing is swedged

into the lobe pieces. Frankly, these are the ones you still have a

tough time getting used to.

As we can all attest, a real man prefers to feel that solid heavy cast

iron or steel in his hand. At least you know that what you have was

machined out of one piece of metal, not some erector set creation that

some engineer dreamed up. Well, be that as it may, tubular camshafts

are here and they are here to stay.

Many of them will run live with oil running through the tube and

actually have small bleed holes in the cam lobes that enhance

lubrication to the follower regardless of the type. The concept is

great – but there is a very mundane and very important step that you

need follow whenever you clean these camshafts. That step is to clean

them THOROUGHLY. Too often, there is not a good inlet for you to

properly clean and brush out the ID of the tube-cam and you will likely

have to remove a soft plug in most of them (see Figure 1).

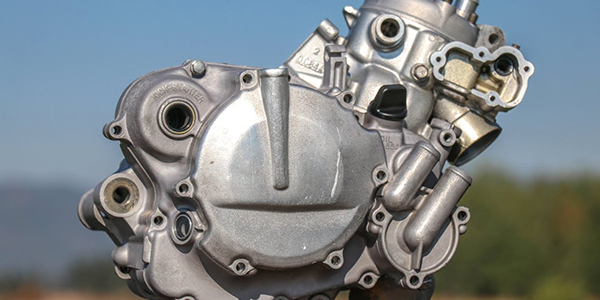

On the left you can see that there is a soft plug in the end of

this tube-cam and on the right you can see that there is a ledge to

determine drive depth. I strongly recommend that you measure the depth

prior to removal of the plug so that you know – regardless of a stop

being present – how deep to drive the plug back into the cam tube.

Another heads up on these camshafts is a warning that those soft

plugs are invariably some non-standard size, and you may have to go on

a journey to find the right one. A measurement prior to removal would

be a good idea here as well. Even with all the hassle it is a

worthwhile step. Cleanliness is next to Godliness when it comes engine

remanufacturing (see “When It Comes to ‘How Clean,’ Do You Really

Know?” page 34, November 2006.).

This next PBT covers a situation that’s a lot more common than

you may think, and can be the source of all kinds of engine failure

warranty dollars if you miss it. There are many engines out there

these days that are either single- or double- overhead cam engines, and

many of them use an oil pressure controlled chain tensioner. Belt-type

cam drives typically will use an independent hydraulic cylinder or be a

spring-loaded type.

What happens if you have an oil-fed tensioner that starts to

hemorrhage oil? You end up with a timing chain that becomes footloose

and fancy free and can cause the following small problems: a horrendous

noise and/or clatter, the chain slaps the timing cover and damages it

to the point of replacement; the cam timing can be messed up enough to

crash the valves; or worse yet, it can destroy a block. Suffice to say

there are going to be all kinds of problems that will arise.

Well, what if you did everything right and bought all new components?

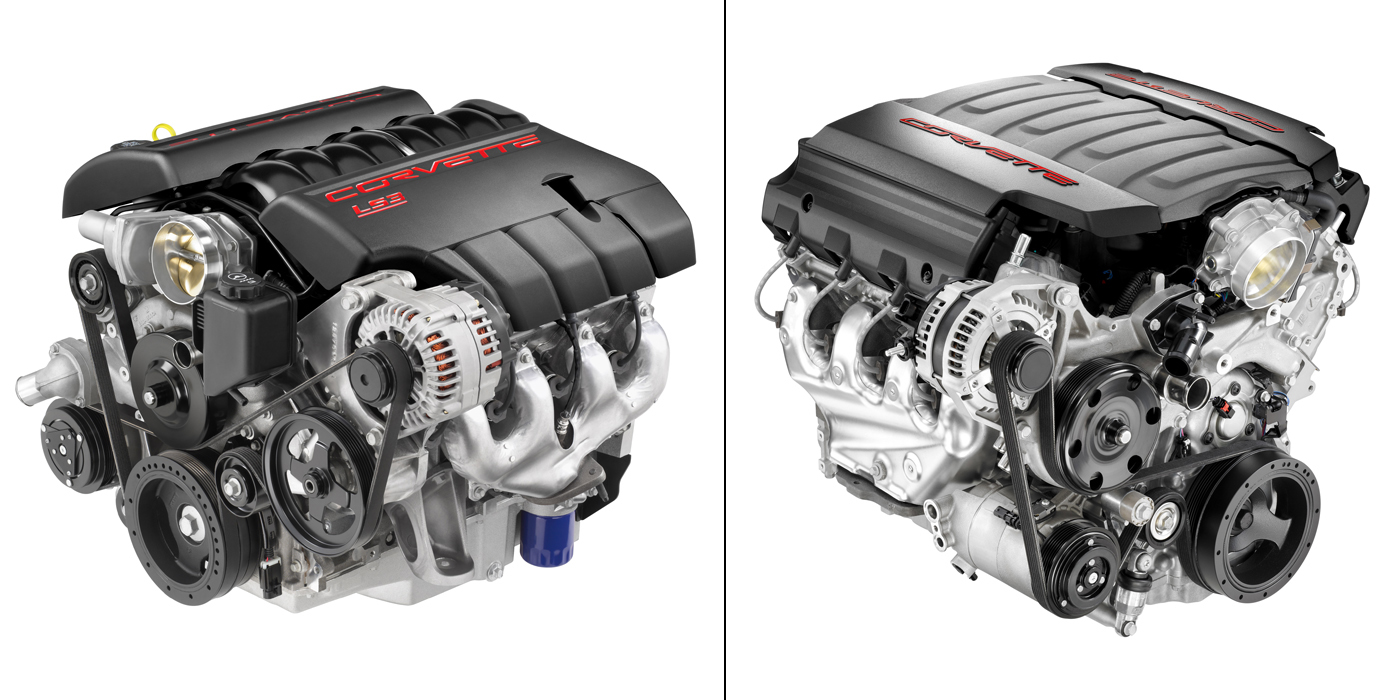

Take a look at Figure 2. The chain tensioner on the left

has a deficient casting. The area circled has a casting bubble and a

thin casting that will fail to properly seal against a block. The

tensioner on the right is what you are looking for. This will seal and

work properly and has no chance of oil hemorrhage.

Now before I start getting emails from every manufacturer in the

industry, let me say this: none of us is perfect and there is no slam.

This information is a pay attention “notice” for those of us out there

that have to use those components and want to avoid potential costly

warranties. That is why we all have quality control departments –

because we are not perfect but striving to get there each and every

day.

I have a friend with a life mantra that says “Seriously

Flawed But Improving Daily.” I like that because it says that though we

can never be perfect we should never stop working at trying to get

there. Kind of like golf, the game that you can never win but can only

get better at.

Remember, we’re all in this together.

Roy Berndt has decades of machine shop experience. He is the EDS Data Acquisition Contractor for the Production Engine Remanufacturers Association (PERA), and Program Manager for PROFormance Powertrain Products, a PER in Springfield, MO. You can reach Roy at [email protected].