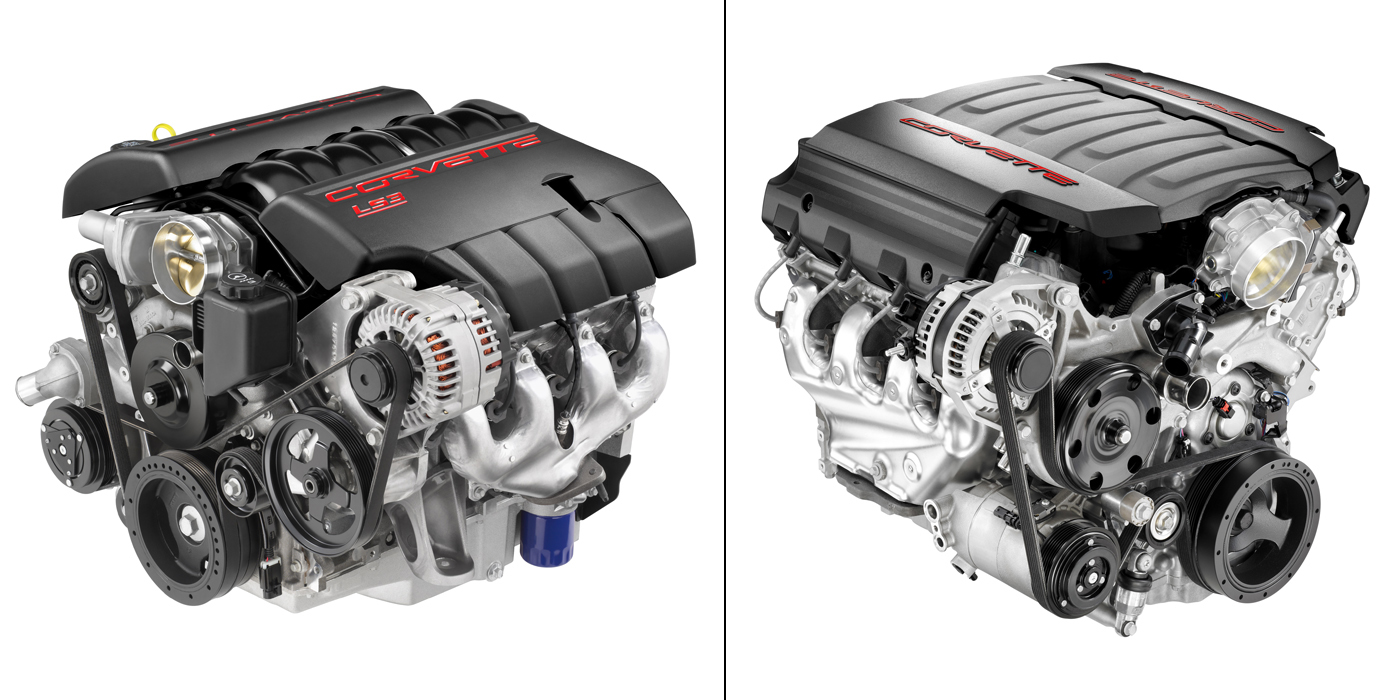

The trouble with timing goes on and on. However when it comes to the right timing on engines, especially single and dual overhead camshaft engines, it is absolutely critical to be correct.

There are very few OHC engines that are not interference, either, so you are very motivated to making certain that camshaft timing is correct. Rotating an OHC engine (especially a DOHC) only once could cost you a lot of time and money (if your cams are not timed correctly) when you have a large number of bent valves. Because, of course, the valve has contacted the piston (see Figure 1).

Generally, how the timing gear is indexed to the camshaft is dictated by either a key or dowel pin, sometimes with offset bolt holes with shouldered bolts. This scenario should not be a cause for any alarm, right? Really, how hard can that be?

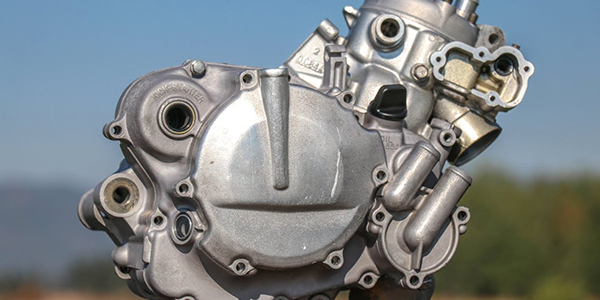

Well, on the 3.7L and 4.7L Chrysler engines, this can be a real challenge to engine builders. First, the end of the camshaft(s) do not have a flange for mounting the gear and the gear area where the cam gear mounts is not large by any means. See Figure 2.

There is a .256? diameter dowel in the end of the camshaft to locate the timing gear. The gear itself has a slot that fits over the dowel pin. See Figure 3.

I have seen the dowel pins protrude off the end of 3.7L and 4.7L camshafts as little as .060? and as much as .150? or more. That is important since it is easy for the slotted timing gear to move ever so slightly on a dowel pin that is very low in the end of the camshaft while being torqued. When this happens timing is close enough to fire the engine. Yet months later the gear may work its way off that pin edge, and no longer be torqued properly.

The gear then has the ability to rotate on the end of the camshaft and will wear a groove in the back of the gear (as seen in Figure 3) and mushroom the end of the dowel pin (as shown in Figure 2). This not only will throw off timing, it will result in valve-to-piston contact (as seen in Figure 1). Of course it causes terrible runability issues as well, even if the valves do not crash into the top of the piston. However, at this point it usually means the engine is coming back, this time out of the vehicle.

The whole assembly is pretty complex (see Figure 4), and it takes very little error during assembly and installation to cause a catastrophic failure. There are multiple chain tensioners, guides and in the center of the block is a driven drive gear. This guide is driven by the crank gear and the gear in behind it drives the camshaft’s chain, which can be a challenge to install and get both chains to be in the correct position.

Because my “time” is up, in closing, let me remind you of the most important thing that I can say when working on 3.7L and 4.7L Chrysler engines that have nearly identical timing. Attention to detail and taking a position of making certain that it is correct is critical to your success, whether it’s an engine reman or a timing chain and gears change.

Roy Berndt has decades of machine shop experience.

He is the EDS Data Acquisition Contractor for the Production Engine

Remanufacturers Association (PERA), and Program Manager for PROFormance

Powertrain Products, a PER in Springfield, MO. You can reach Roy at [email protected].