My column on issues surrounding the PCV system may have bordered on the mundane to some of you, but there was a method to the madness. When you stop to think about how often the PCV system is the root cause of a problem you just can’t talk about it often enough.

I think of it as a reboot. How often have you loaded software or made some dramatic function change on your computer and then forgotten to reboot? I do all the time and have to continue to remind myself of it so I don’t forget (no age comments thank you).

Now, to avoid going off on wild tangents let’s all agree that we know about replacement of hoses, belts, thermostat, we are making full assumptions that the engine is not air bound, or the thermostat is not in backwards, and we’re following good general industry practices. Those “other” issues are the ones to remember.

We are going to focus in on the radiator and coolant mixture that it contains. Ethylene Glycol or Propylene Glycol mixed 50/50 with water is going to be the most popular mixture out there (Dex Cool is another product out there that I will allow you to make your own judgment about). The property of antifreeze as a mixture allows a general operating range from -40° F without freezing to +230° F without boiling (under pressure). What many people fail to recognize are all the anti-corrosive additives that need to be packaged into today’s coolant formulas.

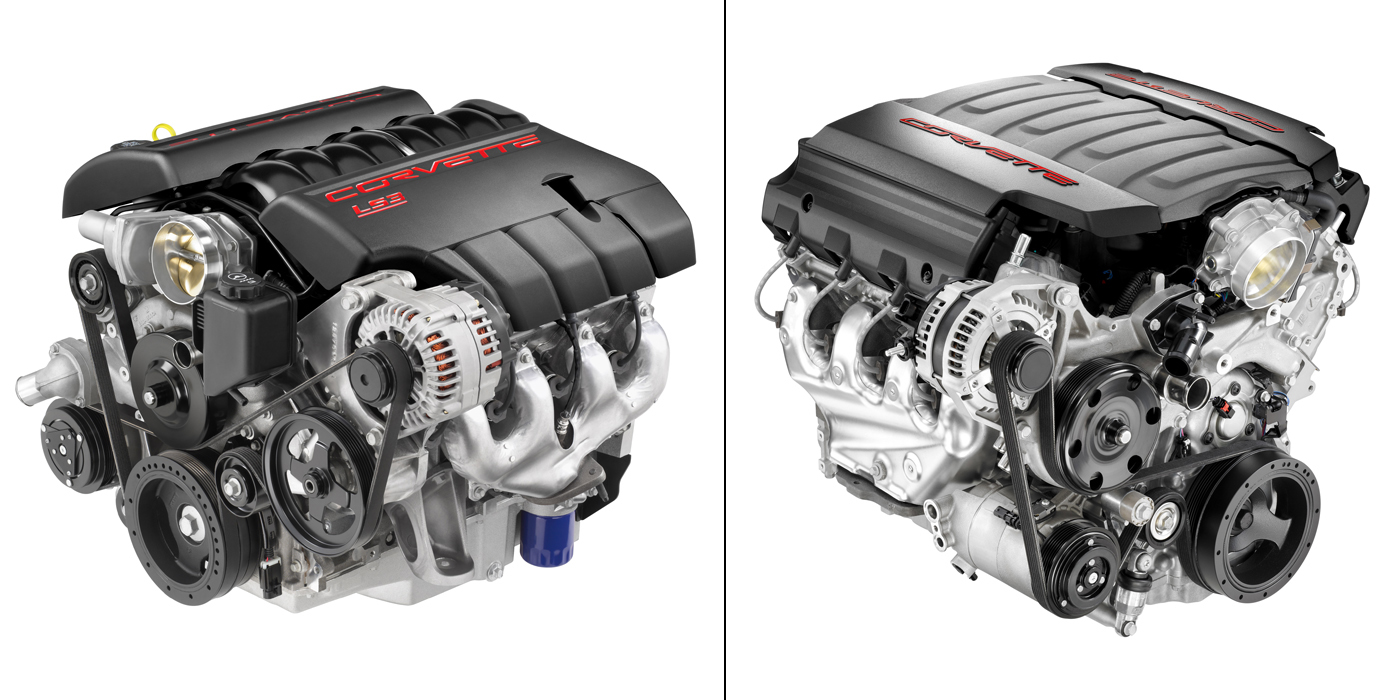

Nearly all engines produced today are bi-metal engines. So you have a 230° F pressure cooker with electrochemically incompatible (say THAT ten times fast!) metals; aluminum, cast iron, copper and lead solder, just to name a few. “So what,” you say? These dissimilar metals exposed within this hostile environment get all cozy and start trading electrons. There is a winner and a loser and the loser is the one suffering from corrosion. Oh, by the way, I just described electrolysis, a word we often use but never really give much thought to: we just know that it’s bad.

As coolant ages and gets heat cycled, the anti-corrosive properties wear down and deplete. The coolant often becomes acidic or alkaline (you can easily test it with litmus paper – yup, the same stuff you used in grade school). The other thing that happens as coolant wears is that it becomes an excellent electrical conductor, which then accelerates the electrolysis. It’s like adding oxygen to fire.

There is a simple test that you can do to determine the health of your coolant with a volt ohmmeter. Begin with a cold engine and remove the radiator cap. Start the engine and allow it to idle until you have seen the coolant circulated enough to know that the thermostat has opened. Set your VOM on DC voltage at a low enough setting so that you can read less than a volt. Briefly bring the engine rpm up to about 2,000 and place the positive probe into the coolant and the negative to your battery ground. You should read .4 DC volts or less – if not, you have coolant trouble and your additives package is cooked (no pun intended).

So your coolant tests out good, your radiator is clean as a whistle and the flow test and pressure testing came back perfect, but you still have an engine that has a tendency to overheat. More often than not, we are talking about one that creeps. It just keeps getting hotter to the point of overheating. Maybe it’s fine on the open road but it overheats in traffic. Everything is in good working order, water pump, hoses, numerous thermostats; it just keeps on getting up there in temperature.

Well, it may be that on the surface the radiator looks fine but it’s no longer thermally effective. Today’s radiators are, for the most part, either aluminum or aluminum and plastic. Over time all those little fins that are swedged onto the coolant flow tubes may lose some of their grip on the tube and that means the fins are no longer capable of drawing the heat from the coolant in the tube flowing across the radiator.

Here’s a simple yet effective test. With the engine running at operating temperature the upper and lower radiator hose need to have a minimum of 20° F differential. If that difference isn’t there, the radiator is no longer thermally effective and you are not getting the cooling that you need to sustain normal operating temperature. There is only one solution: replace the radiator regardless of how good it looks or how well it flow tested. If it cannot draw out the heat from the coolant the engine will overheat.

One closing comment for those of you who now believe that your engine is being eaten away even as you read this: there’s a product out there by different manufacturers that is called a Parasitic Anode. It’s the sacrificial lamb for electrolysis. It’s introduced into your cooling system for no other reason than to be the loser of the electron-swapping contest and ultimately to be completely consumed instead of your cylinder head or intake manifold.

So make certain that your coolant is not an acidic electrical conductor, and that your radiator is not a thermal misfit. By doing so, you’ll give any engine the best possible chance of survival.