World Products

World Products isn’t forgetting Chevy’s original V8, the Small Block. World is already well known for their SBC heads and blocks. Their newest is a 200cc runner version of their Motown cast iron, Small Block heads. The 200cc intake port offers improved throttle response and torque at mid-range rpm for better acceleration off the corners.

A new, 50cc combustion chamber will be available in both 200cc and 220cc Motown heads, producing increased compression with flat top piston engines. The innovative chamber design achieves excellent low-lift airflow by unshrouding the valves. The Motown is specifically designed for maximum performance with flat tappet or hydraulic roller camshafts.

Airflow is 200 cfm at .300? lift and peaks at 295 cfm at .600? lift. The part numbers are Motown 220 (64cc version) – 014150, Motown 220 (50cc) – 014150-50 and Motown 200 (64cc) – 014050, Motown 200 (50cc) – 014050-50.

Bob Walla Racing

The second Chevy engine to hit the streets in the 1950s was the W motor; first released in 348 cid and then later in the ’60s with the famous 409. The not-so-underground market for W motors is still very much alive and kicking these days, possibly even more so than when the Beach Boys first sang about the 409. Bob Walla Racing (BWR) offers two aluminum heads for 409s. One is a replacement head for the best of the street 409s, the ‘690’ head.

It will accept all GM 409 accessories, intakes, exhaust manifolds or headers and valve covers. Its main advantage over the stock head is that Chevy never made any 348/409 heads out of aluminum. An increase in flow doesn’t hurt, either. Another aluminum head from BWR is their raised port version of the stock 409 head.

The ports on the intake side are raised about .750 inch for a straighter shot at the valve for better cylinder filling. Stock type and aftermarket intake manifolds can be adapted with a spacer, as Moroso made for the tall deck BBC. A custom piece, or a sheet metal manifold is available. BWR uses standard ARP head bolts p/n 135-3602 for their heads and offer two stud kits; p/n 135-4002 and p/n 135-4202.

[inpost_gallery post_id=3428 group=”2″ sc_id=”sc1396267280943″]

Racing Head Service

Chevy’s newest engine, the LS Series, has been seeing a proliferation of parts almost since its release. Racing Head Service’s (RHS) newest head shows an application called the LS7 Rectangular Port Head. It’s for small bore LS engines, designed specifically to fit on a 3.900? bore engine.

The new piece provides the ability to apply Gen 4 Rectangular Port technology to the Gen III small bore engines while still using stock rocker arms and intake manifolds. Features include 12 degree valve angle and a .220 inch raised intake runner over the stock LS7, providing a better line of sight into the cylinder and a better short turn.

They use a six head bolt, LSX pattern for increased clamping capacity which also provides better head gasket retention on high horsepower and boosted applications. The LS7 rectangular port head (p/n 54503) is designed around using the stock fasteners with the exception of the fifth and sixth head bolts on the LS7. RHS offers head stud kits for all of their heads.

Trick Flow

Trick Flow Specialties is also offering an LS Series head but this one is designed for the LS3. Trick flow says, “We’ve combined the best features of GM’s LS3 and LS7 cylinder heads with its own race-winning engineering and technology to create the ultimate square port LS cylinder head.” Their GenX 255 cylinder heads also work on other LS engines with 4.000? and larger cylinder bores.

The heads have fully CNC Competition Ported square port runners with a premium, high resolution surface finish for maximum airflow and performance. The specs read out as 255cc intake and 87cc exhaust runners, 69cc CNC-profiled combustion chambers and the valve angles have been changed from 15° to 12° to increase piston-to-valve clearance and allow the use of larger camshafts.

They didn’t stop there as new rocker rail mounts are included to accommodate stock-style LS3 1.7 ratio rocker arms. The GenX 255 heads come in standard- or six-bolt mounting patterns and offer 1.300” Dual Valve Springs (370 lbs.). Part numbers are TFS-32610001-C01 for heads with steel valve spring retainers in the standard bolt pattern, TFS-3261T001-C01 for heads with titanium valve spring retainers in the standard bolt pattern and TFS-3261T003-C01 for heads with titanium valve spring retainers with the six bolt pattern.

For Trick Flow Gen X 255 Heads with 1.300” Dual Valve Springs (448 lbs.), use TFS-32610002-C01 for heads with steel valve spring retainers in the standard bolt pattern, TFS-3261T002-C01 for heads with titanium valve spring retainers in the standard bolt pattern and TFS-3261T004-C01 for heads with titanium valve spring retainers using the six bolt pattern.

Kauffman Racing Engines

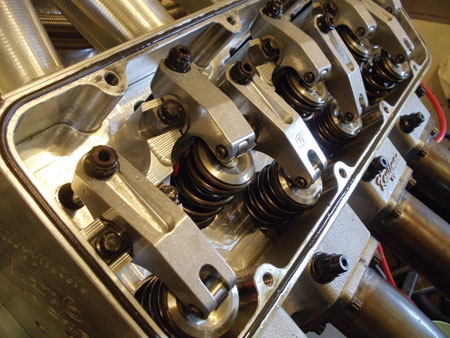

In other GM brand heads, the Pontiac is still very much alive. Kauffman Racing Equipment’s (KRE) latest head is their Warp 6. Specializing in Pontiac engine parts, KRE is long known for making their own heads and even blocks (aluminum and iron). Their Warp 6 is a canted valve aluminum head for what they call, “Heads Up, all out racing!”

With the simple part number of W6, these heads feature fully canted valves, raised intake and exhaust runners, splayed port design, oval intake runners, a single piece rocker shaft stand and are fully water-jacketed castings. The taller runners flow better and there is now a heart-shaped combustion chamber. The oval intake runner makes for higher efficiency and proven higher performance levels per CID than any other head.

There’s no other head like it on the market as KRE got rid of the two center exhaust valves that were side by side. That move also eliminates typical head gasket issues. They offer the KRE W6 with or without assembly and can come with titanium valves. KRE also offers its own head stud kits.

American Cylinder Head

Not all the new stuff is for car and performance street machines. American Cylinder is a world-wide supplier of remanufactured cylinder heads for not only automotive but heavy duty diesel, CNG, and industrial cylinder heads.

Their newly implemented ISO Quality Control and Rottler SG80M churns out heads such as the Caterpillar C15/Caterpillar 3406E with precision seat machining. Every seat is vacuum tested before it leaves the Rottler SG80M, ensuring concentricity and proper seat specifications. For remaining heads, they utilize a unique crack repair system that results in superior longevity and durability.

They also offer 6.0L Power Stoke heads and say the most common reason for this head being replaced is head gasket failure and subsequently having cracked head issues. They have found a bigger problem is the seats when the head is removed, and developed a specialized technique using a Tungsten Alloy seat that is higher quality than factory specifications.

ARP

The folks at ARP often get asked which is better: cylinder head studs or bolts? Of course the answer depends on the installation, but on many street-driven vehicles, where master cylinders and other items protrude into the engine compartment, it may be necessary to use head bolts so that the cylinder heads can be removed with the engine in the car. For most applications, however, studs are recommended.

Using head studs instead of bolts will make it much easier to assemble an engine (especially a racing powerplant which must be serviced often) with the cylinder head and gasket assured of proper alignment. Studs also provide more accurate and consistent torque loading.

According to ARP, when you use bolts to secure the head, the fastener is actually being “twisted” while it’s being torqued to the proper reading. Thus, the bolt is reacting to two different forces simultaneously. A stud should be installed in a “relaxed” mode – never crank it in tightly using a jammed nut. If everything is right, the stud should be installed finger tight.

Then, when applying torque to the nut, the stud will stretch only on the vertical axis. Remember, an undercut shorter stud will have a rate similar to a longer, standard shank stud. This provides a more even clamping force on the head. Because the head gasket will compress upon initial torquing, make sure studs and bolts are re-torqued after the engine has been run.

And if you are going to throw a new set of heads on a motor, why use old bolts or studs? Here’s a few of the latest offerings from ARP:

- Pro Series rocker stud kit for Mopar 318-360 Magnum with OEM-style, nonadjustable rocker arms. The set consists of 16 each of 8740 chrome moly studs, parallel ground washers and 8740 chrome moly steel 12 point nuts. As part of the Pro Series line, they are ground, heat treated and rated at 200,000 PSI – so are these kits:

- Pro Series head stud kit for Ford 4.0 SOHC V6 engines. The set includes 16 each of ARP 2000 head studs, parallel ground washers, 8740 chrome moly steel 12 point nuts, the M8 fasteners that secure the head to the block and a ½ oz. packet of ARP Ultra-Torque fastener assembly lubricant. These fasteners yield an increase of 25% tensile strength over OEM torque to yield head bolts.

- Pro Series kit for Chevy Gen III/IV V8 LS Series Rocker Studs for nonadjustable rocker arms. The set includes 16 each of 8740 chrome moly studs and chrome moly steel nuts that replace the OEM style rocker arm hold down bolts.

There’s the latest and greatest in heads and head bolts so you have more choices when you flip that coin.