Even though flywheel and clutch assemblies are balanced individually within allowable limits, the mating of each part with the crankshaft axis is essential so that they “run true.” Ideally, the balancing of both the crankshaft and flywheel assembly as one unit would be the way to go – since that’s not likely, holding the closest tolerances will yield the best results.

Reciprocating masses should also be balanced to achieve good primary balance, and should include both static balance and dynamic balance.

Primary balance forces are felt when a piston passes through TDC and BDC, the change of direction produces an inertial force (Newton’s First Law: the piston tends to move in the direction in which it was moving before the change). This force, called the primary force, increases with the rise of the engine speed and, unless counteracted, produces a severe oscillation in-line with the cylinder axis.

These forces can be counteracted with weight controls and counterweights of the crankshaft, harmonic balancer and flywheel. These forces, although present in every internal combustion engine, are also different and unique based upon a number of factors: the number of cylinders, inline configuration, opposed cylinders, a V configuration and the different angles of that V.

The inertial forces we looked at based on a piston’s movement are called simple harmonic motion (SHM). In other words, the piston goes up, stops and comes down, then stops and goes back up. During the first 90 degrees of the crank rotation from TDC, the piston covers a greater distance than from 90-180 degrees. It accelerates very fast, plateaus then decelerates very fast.

These points should be understood:

1. The piston travels more than half the stroke during movement of the crank from TDC to the 90 degrees position.

2. Beginning at TDC, the relative piston velocity for each 90 degrees of crank movement is fast, slow, slow and fast.

3. The piston dwell, the period where piston movement is small in relation to crankshaft motion, is much greater at BDC than at TDC.

4. The inertia force at TDC is much greater than at BDC.

Engine balance also requires the analysis of secondary balance, which involves the difference between actual piston movement and the ideal SHM. The use of a secondary harmonic balance is an effective method of eliminating secondary forces.

Frederick Lanchester used this method for the first time in 1911 to balance four-cylinder engines. Even though this device was very effective, the use of soft rubber mountings instead of a damper continued for cost reasons.

The four cylinder inline engine was the primary driver for balance shafts, which due to the asymmetry of their design, have an inherent second order vibration that cannot be eliminated no matter how well the internal components are balanced.

In 1975 Mitsubishi Motor Corporation of Japan introduced a secondary balancer in the 2.6L four cylinder engine. The principle of the MMC secondary balancer is two counter-balance shafts with offset masses driven by the crankshaft at twice crankshaft speed. One counter-balance shaft is rotated clockwise and the other counter-clockwise. The shafts are timed to the crankshaft so that when the piston is at TDC both masses exert a downward force.

To counteract the secondary force on the engine, the balancer exerts an opposing force only when it is necessary. For four-cylinder in-line engines this occurs at 0, 90, 180, and 270 degrees rotation of the crankshaft. This balancing force is downward and upward respectively. The balancers oppose each other causing a neutral effect. The engine attains a state of balance in these neutral positions.

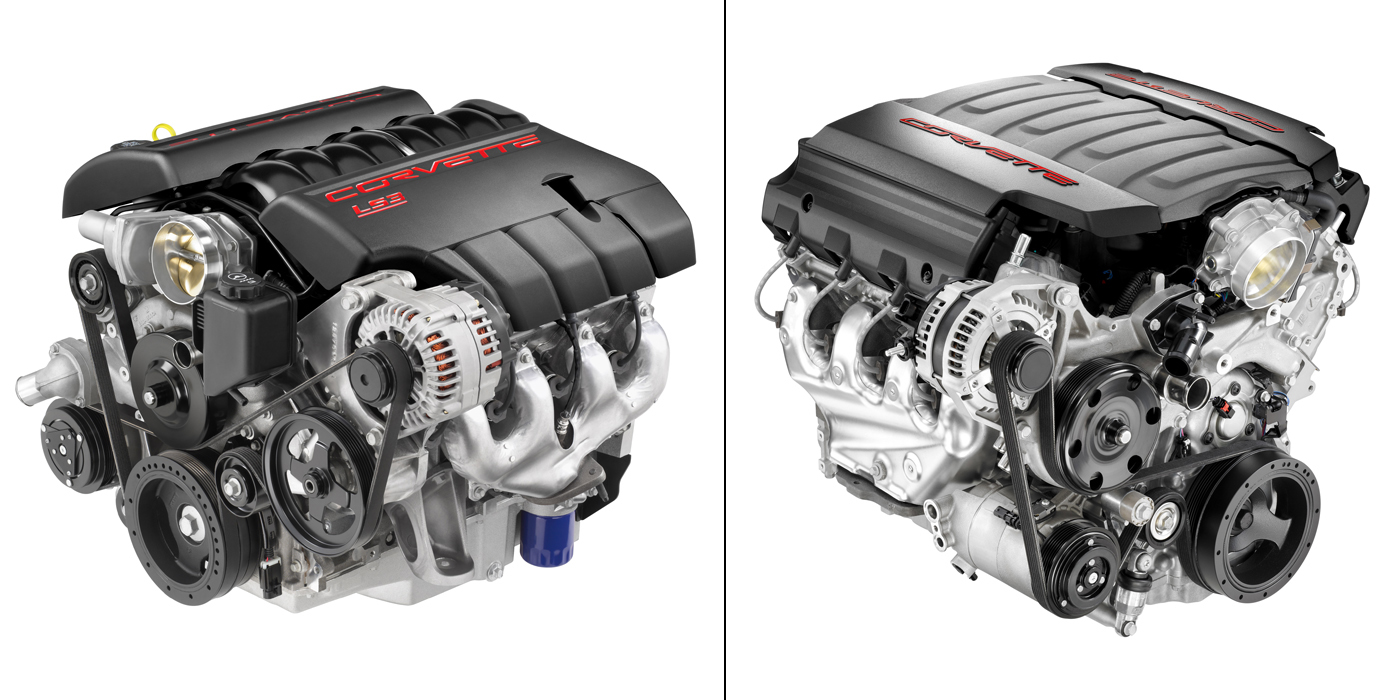

While an optimally balanced V6 engine would have either 60 or 120 degree angles between the two banks of cylinders, many current V6 engines are derived from 90 degree angle V8 engines. While this configuration gives an evenly spaced firing order in an 8-cylinder engine, a 6-cylinder engine develops a loping rhythm.

During each rotation of the crankshaft three of the cylinders fire at 90-degree intervals, followed by a gap of 90 degrees with no power pulse. Much of this issue was eliminated by the use of the split journal crankshaft.

Recently many manufacturers have found it wise to adapt the balance shaft concept as well, using a single shaft with counterweights spaced so as to provide a vibration which cancels out the shake inherent in the 90 degree V6. So if you buy a new vehicle today, from an Audi to a Volvo and everything in-between, you most likely have an engine with a balance shaft.

One of those V6 engines that incorporate the single balance shaft technology is the 3.7L Chrysler engine that utilizes the split journal crankshaft. The single balance shaft goes down the center of the block in an area that you may have thought the camshaft would reside. Since the 3.7L is a SOHC engine it was a perfect spot to drop the single balance shaft unit.

What would happen if you put a balance shaft into the engine out of time? It would just exacerbate the problem and the result would be a shaker instead of a smoothie. Imagine if you did time it correctly but you were actually duped into thinking that you were in time? Unfortunately, that is exactly what we found.

The 3.7L engine has a gear cluster (Figure 1) in the center of the engine that drives not only the balance shaft but the two timing chains as well. And let me tell you, it is a brave man who takes on timing these engines – there are four chains: one “Morse” type chain for timing to the crank; two sprocket type chains for the two camshafts; and a spline type gear for the balance shaft all installed simultaneously.

The spline gear drives that balance shaft and the two sprocket gears drive the timing chains. On the spline gear side of the gear cluster there is a roll pin that locates the index of the gear. We have seen numerous examples where the spline gear has “shifted” and the roll pin sheared.

It is not always easy to see but if you look closely at Figure 2 you will see that the roll pin has been sliced in half and is now out of time and will cause a vibration rather than a counter measure to vibration.

Be aware of this situation because it can be easily missed, especially when the gear cluster appears to be perfect in every other way.

Roy Berndt has decades of machine shop experience.

He is the Program Manager for PROFormance

Powertrain Products, a PER in Springfield, MO. You can reach Roy at [email protected].