Ford recognized a plug removal problem on some of its 4.6L 3v, 5.4L 3V and 6.8L 3V engines and issued a tech bulletin — TSB 08-7-6 — to address the problems. This article supersedes TSB 08-1-9.

Ford’s Modular engine, used in various Ford, Lincoln and Mercury products during the mid- to late-2000’s, has been known to give techs a hard time during a spark plug replacement.

The problem lies with excessive carbon buildup on the plugs, especially on engines that have gone beyond an OEM-recommended replacement interval. This can cause a plug to break in the chamber during its removal, creating stress on the tech and additional labor time to remove the damaged component.

Some engine specialsist who have come across the broken plug problem recommend performing an engine flush the day prior to changing out the spark plugs and letting the engine sit overnight as a way to loosen up the carbon deposits, allowing for less of a chance for a plug to break.

Ford recognized the plug removal problem and issued a tech bulletin — TSB 08-7-6 — to address the problems associated with plug removal on various Ford vehicles. This article supersedesTSB 08-1-9.

According to Ford, some F-150s, Mark LTs, F-Super Dutys, Expeditions and Navigators with the 5.4L 3V engine; Mustangs, Explorers, Mountaineers and Explorer Sport Tracs with the 4.6L 3V engine and F-Super Dutys with the 6.8L 3V engine may experience difficulty with spark plug removal. This may cause damage to the spark plug and leave part of the spark plug in the cylinder head.

Affected engine build dates are as follows: 5.4L 3V and 6.8L 3V before Oct. 9, 2007, 4.6L 3V before Nov. 30, 2007. The engine build date can be read on the left-hand cam cover information sticker.

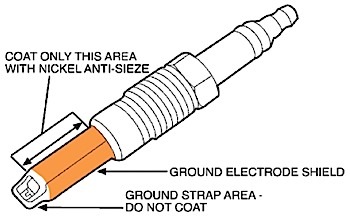

To remove the spark plugs on these engines without damage, it is necessary to adhere exactly to this procedure before removal is attempted.

Caution: Do not remove plugs when the engine is warm or hot. The engine must be at room temperature when performing spark plug service. Removing the spark plugs from a warm/hot engine increases the chance the threads could be damaged.

Engines with the Plug Removal Issue were found in:

• Ford: 2005-’08 Mustang; 2004-’08 F-150; 2005-’08 Expedition and F-Super Duty; 2006-’08 Explorer and 2007-’08 Explorer Sport Trac

• Lincoln: 2005-’08 Navigator and 2006-’08 Mark LT

• Mercury: 2006-’08 Mountaineer

[inpost_gallery post_id=4970 group=”1″]