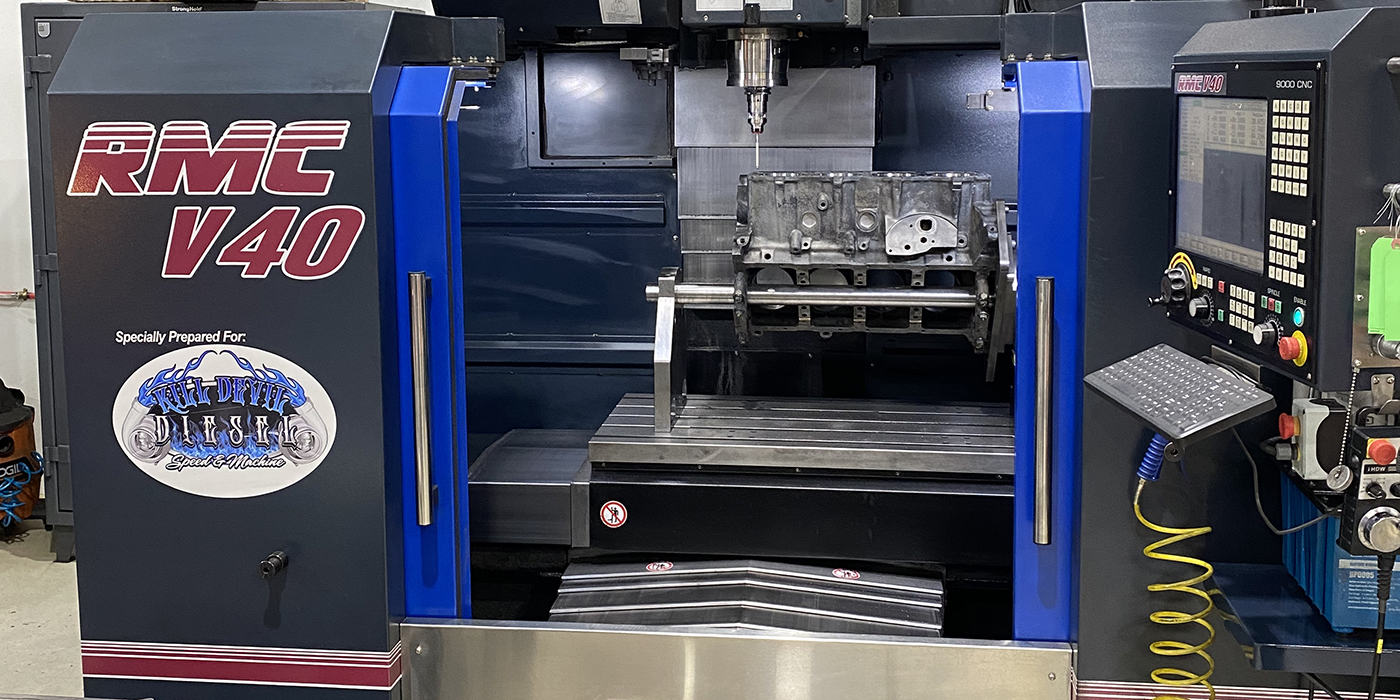

Today, while CNC machines are still expensive, they are much more affordable for the average shop or business than they were just 10 years ago. One of the trends in machining that has taken hold is the mulit-purpose CNC machining center. This machine does the job of several dedicated machines, and is a key factor in allowing a smaller shop or business to compete with larger shops with more machines and workers to run them.

In the past, machine shops were filled with a multitude of specialty machines; one to to drill, another to turn and yet another to mill and bore. Honing equipment has been around for just about as long as the automobile and was done by hand as well. Removing metal, and “throwing chips” was a very hands-on endeavor.

Machinists got the feel of the piece they were working with and knew, almost instinctively, how much material they could remove and how fast just by the sound of the tool against the metal. Machining by hand was painstaking process however, especially in a high volume environment. A milling machine may only be able to take off a small amount of material at a time and was limited by the amount of movement of the table as well as the fixturing and spindles.

What lies ahead? Experts we spoke to for this article say that they think equipment will continue to become more automated, taking the human factor out of it to an even greater extent. Rottler, for example, is coming out with a new vertical stroke honing machine that can hone a V8 block completely by simply pushing a button. The machine will go from cylinder to cylinder and rotate block to the opposite bank and machine will continue to hone that bank until complete and to size.

By having more automated equipment, engine builders will be able to generate more billable labor hours without having to hire more machinists. While shops are already very lean, the ability to run several machines at once will free up the operator to do other tasks. Machinists in the future will likely be loading fixtures and moving parts from machining cell to other machines. It will still require skilled operators, however.

Most cylinder hones take constant attention by an operator to generate round straight cylinders, says one expert. Now that same operator could be boring, decking, lifter boring, stroker clearancing a V8 block on our CNC block machining center while the hone is automatically honing a V8 block at the same time.

[inpost_gallery post_id=3599 group=”1″]