Machines will continue to get more accurate and easier to operate. As materials improve and machining techniques improve, experts say that machines will become smaller. Industry professionals say it is also likely that you will see more and more machining equipped with CNC controls. Anything that requires a lot of direct, hands-on labor to operate such as cylinder hones and seat & guide machines.

Engine builders and shops must be able to bill more hours with less employees in order to survive into the future. As we have seen during the last 20 years of our “Machine Shop Market Profile,” which is a comprehensive study of machine shop operations, pricing continues to hold to levels of a previous era and often don’t reflect today’s economy. Therefore, it will be imperative to run a lean operation, and also, with new equipment, be able to charge a fair price for your services.

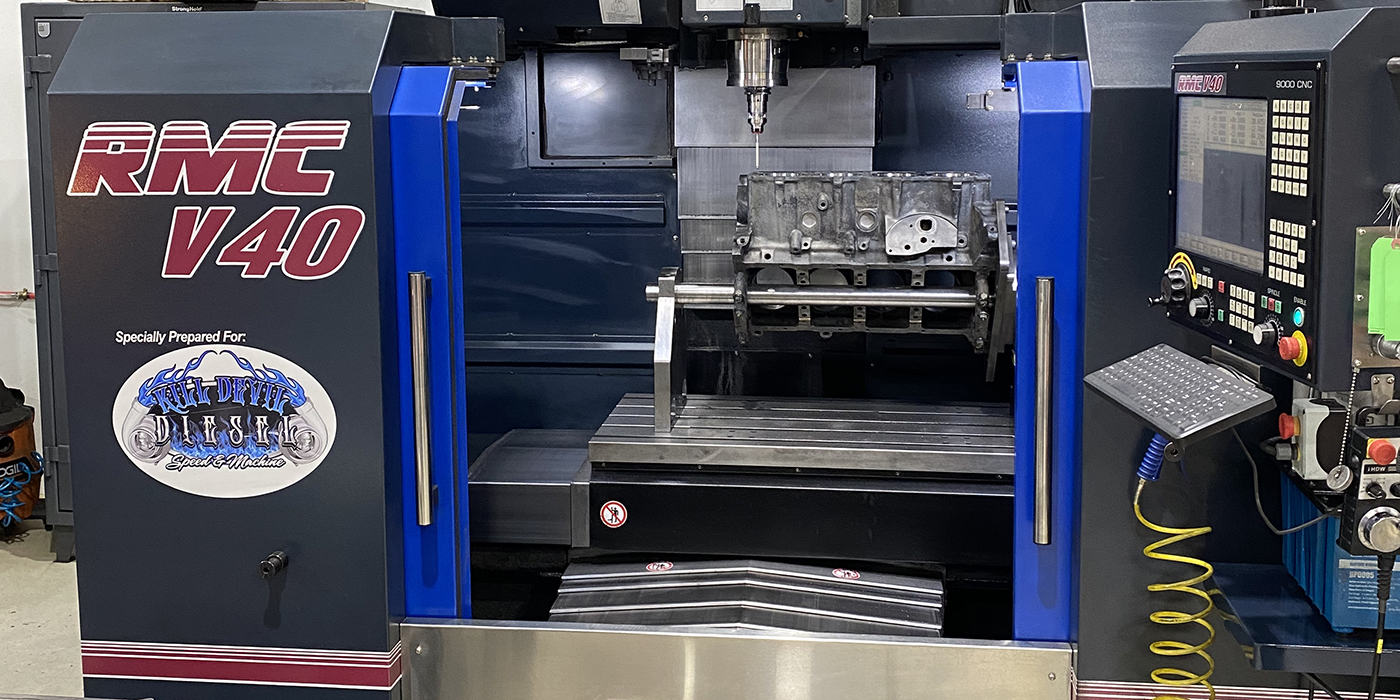

One expert says that as an industry, engine builders have by and large held on to old ways and old equipment longer than other machining-focused industries. Most automotive machine shops don’t own a CNC machine. In fact, our “2012 Machine Shop Market Profile” revealed that only 12 percent of shops own a CNC. In the next 10 years, many experts believe it will be a necessity and not an option.

With the way parts are designed today, it will be impossible to complete jobs profitably without one. CNC machining centers like those from Centroid, Rottler and others, operate as profit centers as much as machines. They are essentially turnkey businesses that the engine builder will then have to go out and find the market for his products, but the expertise and precision will be mostly handled by the CNC.

Some experts we spoke to believe you may see robots on such mundane operations as loading a valve in a valve refacers. Most jobs or parts vary widely in size and shape from part to part. However, you may see a robot be able to load a valve in the chuck of a valve refacer for grinding or a connecting rod for boring, or possibly a block into honing machine.

Another key trend for the future will be the growth in the use of digitizing probes, which experts believe will be very prevalent in the machine shops of the future. As software improves the ability to use digitizing for other than just copying ports in a cylinder head is growing dramatically. This technology allows operators with little training on CAM systems to duplicate parts much more easily.

Machining in the future will be much more scaled down to a level to where a small shop will be able to produce as much as a large shop today. With CNC prices coming down to affordable levels that can be operated more easily by fewer skilled workers, it is going to turn the industry in many directions.

Parts will be able to be manufactured by printing them to a 3D printer in some cases, and in others a 3D printer can make prototypes that can then be produced on a CNC for small scale manufacturing purposes. Some of these dreams are already a reality, but in the future, the sky’s the limit. And at least you won’t need to worry about running into one of those “flying” cars.