Balloons Belong at Birthday Parties Not in Transmissions

I rebuilt a 454 GM engine that went into a motorhome application. It ran well, and no problems immediately appeared. But later on, it was towed in with a main bearing failure in the thrust area. I gave the customer another engine, and a month later it came back with the same problem.

Upon further investigation, I discovered that the torque convertor had ballooned, causing the engine and also transmission problems. It seems that it was severely overloaded. The motorhome owner was a flea market vendor and was towing a trailer that was way too heavy for his setup.

Lesson: If you build an engine with an automatic transmission for severe-duty, nitrous, supercharged or just high-horsepower, be certain that the owner installs an anti-balloon torque convertor.

Hopefully, you will avoid the same problem after reading this.

Lee Johnson

Pro Performance

Denver, CO

Note: Crankshaft grinders are used to getting “defective” crankshafts returned to them with thrust flanges wiped out due to this type of problem.

– Engine Pro Technical Committee

Flyer Selling and Swapping

An easy and cheap form of advertising is the 8-1/2˝ x 11˝ flyer. For about a dime, you can print a flyer, and most quick printers will help you with the design. A broad generic flyer could take on the purpose of a resume, telling customers about you, your services, hours and contact information. A common practice is putting out a flyer offering free or discounted services. One shop I know advertises a free case of oil with any engine build.

Once your flyer is printed, make a deal with other merchants in your area to provide a spot for their flyers in your shop if they will do the same for you. You will get exposure to a different customer base in another location. Picking like-businesses, such as a towing company or a body shop, will increase your advertising results.

Steve Rich

Sterling Bearing, Inc.

Kansas City, MO

How to Resize OHC Oversize Lifters

Occasionally, you will need to buy lifters to make valve adjustments because the one piece tappet is of a specific height and must be changed. This is the case with most overhead cam engines these days. But what do you do when the lifter you buy is a thousandth or two oversize? You could return it, but that takes time. You can also micropolish it on your lathe to obtain the correct diameter, but how do you hold it?

Here’s how: Take a piece of aluminum stock that is a slightly larger diameter than the lifter and machine it to the lifter ID. Wood can also be used. The total length of the aluminum/wood only needs to be about 3˝ long and you only need to machine the diameter to a length of about 1˝.

You can drill a hole all the way through the piece and use a countersink to cut a taper on the end that you machined. Machine a piece of steel or aluminum that is the same diameter of the big end of the countersink hole you machined in the part. Next, machine a wedge and drill and tap it for a 1/2-20 bolt that will slip into the 1/4˝ you drilled in the body. Its length should be only as long as the total length of the body, including the wedge you just made. The wedge should sit flush with the end of the body. The body can also be made from a piece of wood doweling.

Now take the body, remove the bolt and wedge, and cut in two places, 90 degrees apart so they will be able to expand when you tighten the wedge. Insert the bolt and wedge back into the body of the fixture and place the lifter on the machine end. This diameter should be only .001˝ to .002˝ smaller than the lifter ID. Place your fixture into the lathe and use your crankshaft polisher to reduce the diameter of the lifter to the diameter you desire.

See the video on my YouTube channel: http://bit.ly/1e92eDr

John Edwards

Cost Mesa R&D

Automotive Machine Shop

Costa Mesa, CA

Keeping Valve Locks in Place

By using marine grease on the end of a thin flat head screwdriver, you can rest the lock on the grease while you assemble heads with puck style lifters. This way you are not

constantly dropping the lock down into the head.

Greg Goss

Engine & Performance Warehouse

Denver, CO

Manufacturer Shop Solution: Standard and Reverse Rotation Marine Engines – What to Look For

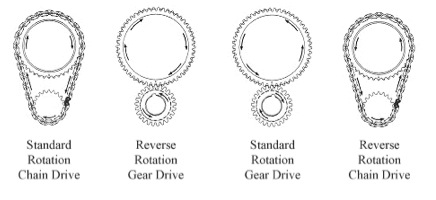

Boats with twin engines usually turn in opposite direction so the torque reactions of the engines cancel each other out. The following four drawings show how the crankshaft and camshaft turn in the four combinations of drives. Some of the parts in these engines may be interchangeable, but will not function properly and can create problems for rebuilders.

Crankshaft – Some of the reverse rotation cranks have the oil holes drilled symmetrically opposite. Check this closely.

Camshaft – In the above combinations none of the cams are interchangeable. The lobe timing and/or the distributor drive gear angle are different.

Distributor/Oil Pump – In all of the applications, we know of both the distributor and oil pump turn the same direction regardless of the crank rotation. This is done by making the angle of the drive gear on the cam and its mating gear opposite, when the cam turns the opposite direction. This makes the thrust of the gears in the opposite direction. For example, the SE Chevy thrust is up and is taken by the base of the distributor housing and the drive gear.

If the cam rotation and gear angle are changed, the thrust is down and there are no provisions for this in a stock distributor. A ball bearing distributor or magneto is required.

When working on marine engines, be sure you know what the components intended usage is and do not vary from it.

George Richmond

Melling Engine Parts

Jackson, MI