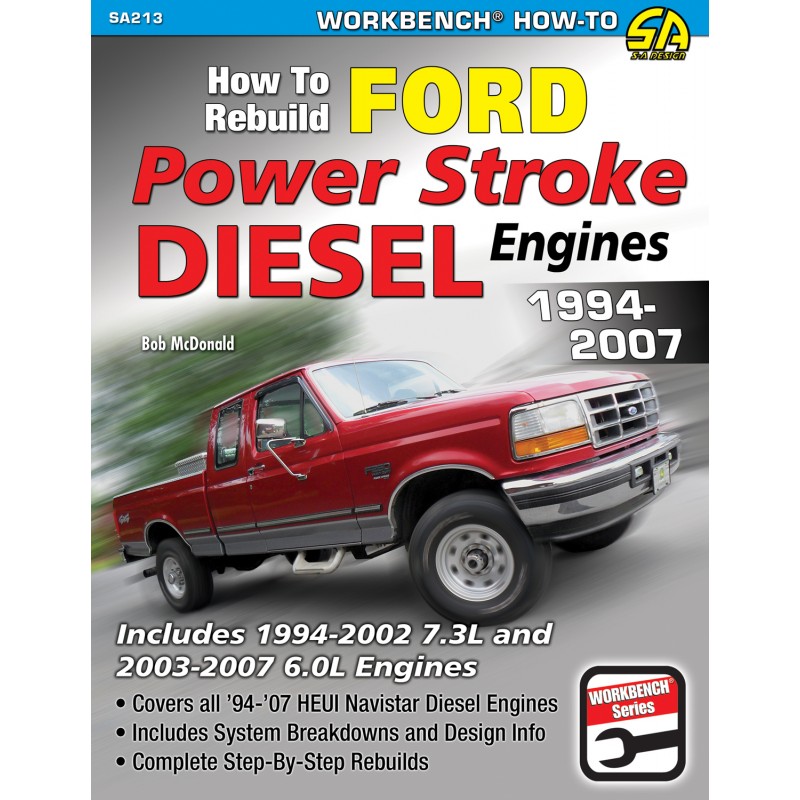

Bob McDonald, who contributes diesel stock and performance articles for Engine Builder magazine, including the column “Diesel Dialog,” has authored the book “How to Rebuild Ford Power Stroke Diesel Engines 1994-2007.”

The book covers the vast majority of Power Stroke diesel engines on the road, and gives you the full story on their design. A full and complete step-by-step engine rebuild is also included.

The book’s appeal extends further with a wide range of engine-building tips, charts, graphs and information-packed sidebars to share even more information.

Detailed graphics showing the engine’s various system designs are also a unique feature of this book. McDonald includes information on the 1994-2002 7.3L and 2003-2007 6.0L engines used in Ford’s popular F-150, F-250 and F-350 pickups and industrial work trucks.

McDonald says he has been intrigued by internal combustion engines (both gas and diesel powered) since childhood, and chose to make auto and truck engine repair his career at a young age.

At sixteen, he began working at an automotive dealership. His career led him to work at several different dealerships, including a farm implement dealership, learning the intricacies of modern planting and harvesting equipment.

Seeking independence, Bob chose to open his own vehicle repair shop specializing in diesel repair. Additionally, he launched Atlantic Engines in Granite Falls, NC,a business venture focused purely on high-performance engines. He has also been a competitor in the popular Engine Masters Challenge competition.

The 8.5 x 11” softbound book (ISBN: 978-1-934709-61-0) may be ordered for $24.95 plus $6.95 shipping and handling by calling CarTech at 1-800-551-4754![]() or by visiting www.cartechbooks.com.

or by visiting www.cartechbooks.com.