Jeep 3.8L Oil Pressure Problem

Many late model 3.8L Jeep engines are losing oil pressure at the oil pump due to failure of the bypass valve. This results in destruction of not only the crankshaft, but the connecting rods. To fix the problem, you need to find the bypass valve inside the plastic timing cover. To get to the valve, you need to disassemble the cover and remove the oil pump.

Chrysler sells an upgraded bypass valve made of metal instead of plastic, which solves the problem, helping your engine build go farther in the long run.

My machine shop customers also tell me that replacing the late-model rods with the earlier forged rods will help make the engine more durable. There may be modifications required to make the early rods fit in the late engine.

Roy Maloney

Engine & Performance Warehouse

Houston, TX

Avoiding The Skinned Knuckle Syndrome

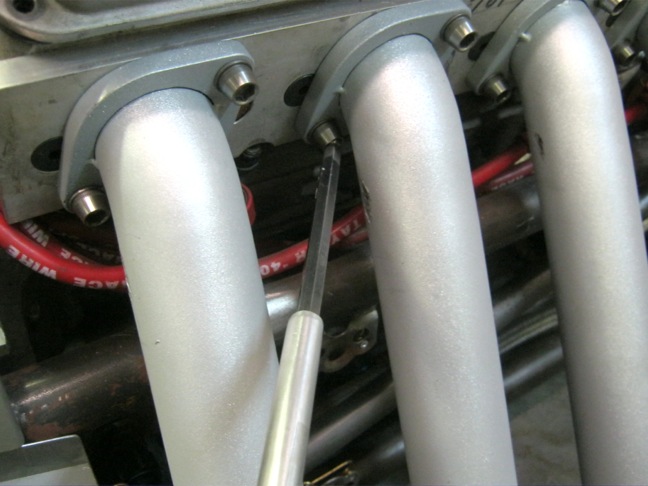

Header bolts and other bolts in tight locations can be troublesome to remove and install, especially in custom fabrications where there is limited accessibility.

A solution is to use internal wrenching bolts (Allen bolts).

To use allen bolts, taper the head as illustrated, and purchase or fabricate a long ball end wrench for installation and torquing. This method may alleviate the “skinned knuckle” syndrome that so many of us know so well.

Archie Frangoudis

Archie’s Racing Service

Nashua and Merrimack, NH

RV Engine Opportunities

Machine shops are not building as many “daily driver” complete engines these days; a lot of that business has gone to the PER and the junkyard. There are still a ton of engine builds, but they are mostly generated from two broad categories; work vehicles and play vehicles.

These vehicles retain their value for a long time and are ripe for custom building to improve performance.

An often overlooked opportunity from the “play” category could be found at your local RV dealer. It turns out there are more than 9 million Americans who own RVs and that number is on the rise because of the versatility and affordability of today’s RVs. Shipments of new RVs in 2013 are expected to reach 310,000, up 8.4% from last year. Because of the cost of these “play” vehicles and the extra stress on their engines, there is a lot of opportunity for cylinder head and engine rebuilding.

Here is a tip: Connect with dealers and rental companies in your area. A simple phone call can be a start. Let the RV specialist know that you rebuild cylinder heads which often require crack repair and new parts, resulting in a high-profit job. And don’t forget to out-service the competition by selling the RV dealer a “package” includes the parts required to install that cylinder head or engine.

Steve Rich

Sterling Bearing, Inc.

Kansas City, MO

Why Torque Plates Should Be Used On FE Ford Blocks

Some claim it is not necessary to torque hone FE Ford blocks. In fact, I am the only one of many shops in my area that even has an FE honing plate in my collection. Don’t believe that an FE block needs to be honed with a torque plate? Torque honing, especially on an old 428 or any FE Ford block is essential.

On a particular 428, as I do with all blocks, I checked each bore size in four directions, 90 degrees, 180 degrees and 45 degrees both ways before torquing the CCA two inch torque plate on top of an appropriate used head gasket to the block. After torquing, the number one cylinder changed over .003˝, and also changed the widest location from 12 and 6 o’clock to the 10 and 4 o’clock degree direction. The measurements on all seven other cylinders changed as much as .002˝ plus. There were changes in new directions as well.

This proves that to hone an FE block right, always use a torque plate.

‘Animal’ Jim Feurer

Animal Jim Racing

Lacon, IL

Extracting Broken Bolts From Aluminum

Broken bolts that are seized in aluminum with corrosion often do not break loose with penetrating oil or freeze spray because they are too tight. And we often shy away from using our torches for fear of melting aluminum since it does not glow

before melting, unlike cast iron.

Here is my method: Use your propane torch at normal temperature. At this temperature it will not melt aluminum. We prop the torch up to the head for five minutes of heat. So far, 100% of seized bolts have come out of the aluminum.

Whether they are sticking out or sunken in and needing to be pre-drilled and extracted, we’ve found this method to be a lifesaver.

Jeffrey Myers

MAR Automotive, Inc.

Philadelphia, PA

How Do You Slice It

If I had a nickel for every time I’ve been asked “What is the best way to cut braided steel hose?” I’d have more money than Bill Gates.

While there are about as many answers to this question as there are skilled automotive techs, there are two frequently utilized techniques. Let’s have a look at both.

A lot of technicians use a simple cut-off approach using a hack saw, tin snips, die grinder, a Dremel tool fitted with a cut-off wheel, or even a chisel. In this instance, the hose is usually wrapped tightly with electrical tape to hold things together and the selected tool used to make a cut at the designated area. While this approach can be reasonably successful, care must be taken to insure a clean cut, and the hose should be cleaned/blown out to remove any rubber fragments and/or stainless steel wire bits.

While the above method is probably the most common, my preferred method is to use a braided steel hose cutter. This job specific tool is reasonably inexpensive and available at a variety of sources. It is much better suited to the job, safer to use and the result is a nice clean edge ready for assembly. Another advantage is that this method always delivers a nice smooth clean cut and rarely, if ever, leaves any debris.

Whichever method you choose, it is always a good idea to wear a good pair of heavy leather gloves and eye protection when cutting and assembling steel braided hose.

Lamar Whitman

Engine Pro Tech Committee