Whenever we see an unusual engine in a car or truck, it tends to get our attention. With most of today’s vehicles having either in-line or V configuration gasoline or diesel engines, there isn’t a whole lot of variation. However, this wasn’t always the case. The early 1900s saw a myriad of crazy and almost nonsensical designs going into cars. By about the 1950s though, most of the wacky engine configurations were on the wane. However, no one told the Commer Motor Company of Luton, England.

Commer was a truck manufacturer that operated from 1905 until 1979. Long since forgotten, perhaps the only notable part of their history was an engine built for them by the Rootes Group, officially titled the Commer TS3 and unofficially called the “Commer Knocker.” The engine was as unusual as it was unique and was fitted in Commer trucks from 1954 until 1968.

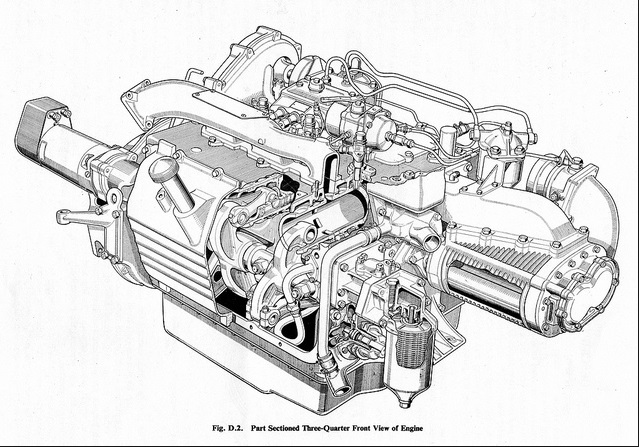

The “Commer Knocker” is an opposed piston engine. No, this doesn’t mean it was a traditional ‘opposed’ engine or ‘boxer’ design; the opposed piston engine is actually something quite different. The design is a two stroke cycle in which each cylinder has two pistons. If you aren’t familiar with this design, it may seem a little off the wall, so here’s a graphic of the Commer TS3,

The Commer TS3’s design is that of a three cylinder supercharged diesel. Each cylinder has two pistons, for a grand total of six, with the crown of each piston facing the other. Each piston is also attached at the other end to a connecting rod, which fits a series of rockers and then attaches to another connecting rod, which connects to the crankshaft. Of note, each cylinder has its own crank-pin, rather than sharing one with the opposing piston. Unlike many opposed piston engines, the TS3 only has one crankshaft, rather than two. The engine is supercharged, with a massive rotating lobe blower feeding air to the intake manifold. The total engine displacement is 3.25 liters, and power output is around 105 horsepower, with a whopping 270 ft. lbs. of torque. Compared to other diesel truck engines of the time, the TS3 was quite powerful and achieved an output comparable to engines of a much larger size.

The engine employs a modified two stroke compression cycle, as illustrated by the graphic above. One piston is considered the exhaust piston, while the other is designated as the air piston, as indicated by the corresponding port above each. The exhaust piston has a minimal lead compared to the air piston, to ensure the exhaust port is sealed as air is rushing into the cylinder. As both pistons converge on each other, and just before their crowns meet, fuel is injected into the cylinder, igniting soon after by way of the intense heat and pressure. As the pistons are pushed apart, the exhaust gases are expelled via the exhaust port. Once the outer dead center position is reached by both pistons, the air intake port is exposed, and the process begins anew, as the pistons converge on another compression stroke.

As the TS3 aged throughout the 1960s, Rootes began developing a four cylinder variant of the TS3, dubbed the TS4, which would produce added power and featured a more modern design. However, the purchase of the Rootes Group by Chrylser ultimately spelled the end of the opposed piston diesel engine. Throughout its history, the “Commer Knocker” found its way into a variety of trucks, including the one below.

There may still be a few “Commer Knockers” hoofing around Britain, but the Commer TS3, the Commer Motor Company, and the Rootes Group are all long since things of the past now. It wasn’t so much a failure or success as it was an oddity, and whether it was glorious or idiotic depends on your perspective. Notwithstanding, as with many things, the Commer TS3 engine is now consigned to history.