QuickTime, a leading manufacturer of high performance drivetrain and bellhousing products, has announced it launched its all-new Modular Flexplate (patent pending) for a wide variety of engines, including small and big-block Chevrolet and Ford. Each application is designed to handle the stresses of high horsepower, high rpm engines.

QuickTime, a leading manufacturer of high performance drivetrain and bellhousing products, has announced it launched its all-new Modular Flexplate (patent pending) for a wide variety of engines, including small and big-block Chevrolet and Ford. Each application is designed to handle the stresses of high horsepower, high rpm engines.

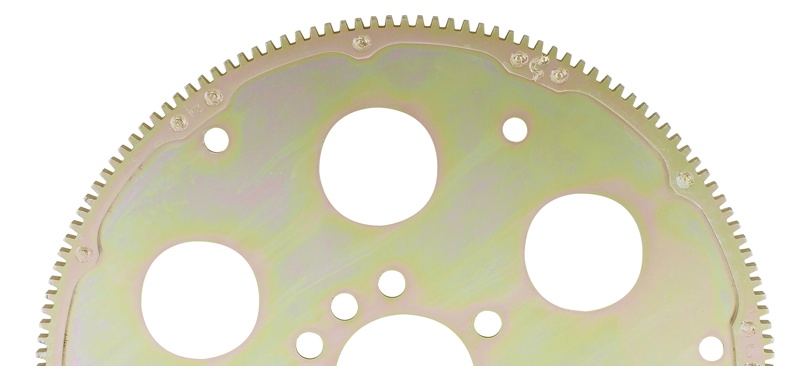

QuickTime’s new Modular Flexplate features full 4130 chromoly steel construction that’s twice as strong, 10-percent lighter and better balanced than OEM-style flexplates

Engineered for unsurpassed strength, accuracy and performance, the Modular Flexplate brings an age-old product into the 21st Century. Since the 1920s, nearly all flexplates have been manufactured using the same method; a high carbon steel ring gear is MIG welded to a low carbon stamped steel center section. This process poses a number of problems, including weak weld joints, warping and metal crystallization, which negatively affects both durability and accuracy. In addition, all ring gears are now coming from off-shore.

QuickTime takes a whole new approach to flexplates by using a laser cut 4130 chromoly steel center section that is joined to 4130 chromoly steel ring gear segments using (18) separate 4130 pins, which are pressed as well as laser welded. This approach results in a SFI 29.1 certified flexplate that is both 10-percent lighter than and twice as strong as OE-style flexplates. In addition, the Modular Flexplates are accurate in every dimension: circumference within .002, Rollout within .010, and balance within 1 gram.

QuickTime Modular Flexplates are made in the USA and are available for 1955-1996 small and big-big block Chevy and Ford applications, starting at an MSRP of $283.95.

For more information: LakewoodIndustries.com.