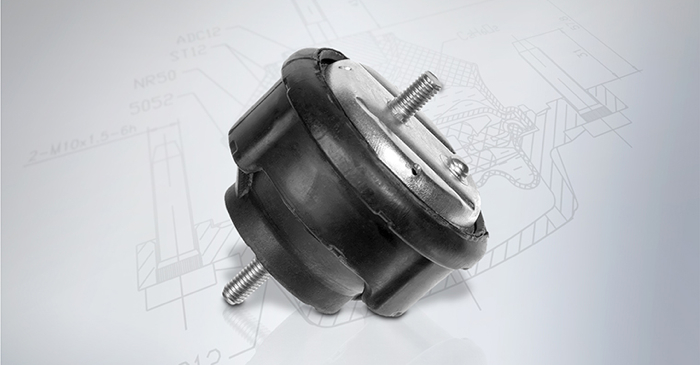

Meyle engineers recommend that engine mounts always be checked when doing a routine vehicle inspection. Signs of a defective engine mount are fissures in the rubber material, metal peeling or, where hydraulic engine mounts are installed, leakage. If a mount is diagnosed as being defective and replaced accordingly, customers will instantly experience the difference: the vehicle’s road holding behavior and driving comfort are significantly improved.

High engine loads, excessive vibration and frequent temperature changes from ambient air to operating temperatures often result in early part failure, manifesting itself through unresponsive steering and reduced driving comfort.

Material quality is the key to ensuring long part life despite the high static, dynamic and thermal stresses to which the parts are exposed, and is therefore a prime concern of the company’s engineers. All the materials employed are specially chosen to match the respective vehicle and undergo rigorous quality control procedures from design to final product.