Like Perry Mason, I don’t trust hearsay information. When I am not sure of something, I consult a book, website or ask someone who is an expert about the information I seek.

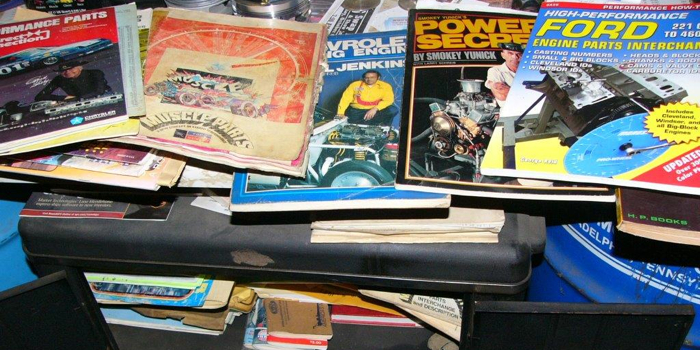

Having been in an automotive and racing career for 50 years, I have a huge collection of Chilton and Motor Manuals, from 1935 to present. Another valuable source of information is a good collection of SA type “How-To“ books.

I also have several specific years of dealership manuals plus tech flyers, bulletin notes, Engine Builder magazines, and my own operation notes and files. I keep detailed files on all my jobs. The customer gets a copy also.

Another good information source is my 50 years worth of parts catalogs. They are full of valuable info and I never throw them away.

Be careful, however. I’ve found that just because they’re printed doesn’t mean they’re perfect. I have found mistakes in some books, including a popular “How-to Ford” book telling me to torque the Cleveland valve covers to 75 pounds.

When doing older engines, the dated literature is very valuable. A lot of that info still applies. Some of my favorite “How-to” books were Grumpy Jenkin’s and Smoky Yunick’s. They both told it in plain words.

Smokey – what a guy! I had the extreme pleasure of knowing him. Twenty-five or so years ago when I bought his “How To Build A Chevy” book, it came with a stapled stack of pages inserted inside the cover, called “Smokey’s Addiams.” The pages were full of corrections and additions Smokey apparently felt needed to be told, and had them stuffed into the first editions. Priceless! I would not take $1,000 for that book and Smokey’s “Addiams.”

I met Smokey in the ‘70s during my Indy Car days. I did alignment and wheel balancing for Bear Manufacturing part time. Indy time was my busman’s holiday and I even got paid for it.

Smokey’s Number 78 Gasoline Alley Garage was right across the aisle from the Bear Alignment and Wheel Balancing shop where I worked all May. Although my job with Bear was wheel balancing, working the alignment racks and doing PR, when I had time, I visited the legendary engine guys in the old wooden garages of Gasoline Alley whenever I could.

One day Smokey had the race car outside his assigned garage. The Chevy small block engine had the heads off and Smokey was going to town with a die grinder. I walked over to see. He was grinding more valve to piston clearance for the intakes, with the pistons still in the block. He told me, as he relit and puffed his pipe, he was doing so because he had advanced the cam. I was dazzled, because I had done the same thing with my drag race engine for the very same reason once. You have no idea what that meant to me to see a legend like Smokey dealing with a situation using the same grass roots basic common sense I had!

What I learned during those 25 years I worked at Indy was the most valuable information that could be applied, not only to my drag racing, but also my customers’ projects at my shop.

I have a Jenkins story also. I did not actually witness this one, but it is from a good source. At a national event Grump hurt his engine, bending a valve stem. To be able to use those precious Jenkins-prepared heads, Grumpy bent the valve stem back as straight as possible with a skinny piece of pipe, and made the next round.

That one I did not try. Well, now that I think about it, yeah, I guess I did. It was at Atco in ‘89 and I too ran the first round at that event knowing I only had 7 cylinders that would work. That ‘89 Atco race is a huge story itself!

Of course, that Grump story is hearsay, but it’s too good not to tell, don’t you think?

I have stated before how much help the Internet is to me today. Hell, I hardly ever use a catalog anymore. I just type in the parts or information I seek into Google.

But again, be careful, especially with message boards. You’re trusting your sources without really knowing who they are – and remember that Wikipdedia can be modified and updated by anyone. I’ve found some real head scratchers on Wikipedia, including one entry that says the Drag Racing Throttle Stop goes on top of the carb?!

When I need to call someone for information, I usually start with: “I have a stupid question,” and continue with “But I need the stupid one answered before I can ask a smart one.” It is a light ice breaker, especially if I’m calling someone for the first time. And it usually gets a little chuckle.

What is really stupid is not to ask. For me, knowing the facts to do a better job for myself and my customer trumps all, even pride. But be ready. The right answer may be something you do not want to hear.

Much can be learned consulting and comparing notes with colleagues and even clients. But carefully consider their comments and perhaps double check with another source to be sure their view is valid.

Be sure the source understands clearly what you are asking. And be sure he or she knows the subject. A hands-on tech person is usually best.

One time I had a customer service tech guy tell me I needed a cam button to cure my customer’s chronic problem of bronze distributer gear teeth from prematurely wearing. When I called the cam company I had requested a knowledgeable Ford tech. I told the tech guy it was a Cleveland Ford right away, but his response clued me in; he was not aware Ford Clevelands had cam retainers.

Later, while freshening that Cleveland engine, I found the problem myself. With the block still bare, I had installed the pump, shaft and MSD distributor. The distributer lacked about .020˝ to seat but my customer had not noticed and tightened it down when he built the engine. The heavy-duty aftermarket custom oil pump shaft was too long and was binding.

That is not the first time I have experienced that problem. The last time was just last year while freshening a BB Chevy stroker race engine. One of the tangs had broken off the bottom of the HD oil pump drive shaft and was stuck up in the bottom of the distributor and bronze gear.

I like a minimum .025˝ to .065˝ perpendicular clearance.

There are times, of course, that I cannot seem to find an answer to my quandary. So then I have to get scientific myself, until I am satisfied with the answer. Sometimes it comes down to inventing new ideas. I have been fairly lucky there, with more success than failures.

In science class, eons ago, I learned that in order to prove a theory, 100 test experiments are required under the same exact conditions. In our shops we would go broke at that rate. Perhaps I could get a Federal Grant next time I want to experiment.

Sometimes information from books and conversations is revealed slowly, like peeking in a door – and sometimes it’s like having someone kick it wide open so all is revealed.

Another valuable source of information I have found are worn out and broken parts I have saved over the years. In my main shop I have some used, old parts I use as measuring tools. I have an organized shelf of used camshafts of all kinds in boxes for mock ups and to verify cam bearing fit.

I keep most of my old parts and other items in my warehouse next to my shop. This old, two-story, wood frame building — at one time a small Packard dealership – also harbors used and new parts, including engines that are obsolete.

Many times I run over to that old warehouse to verify something. Usually what I find is very helpful and enlightening. And in this time of “Nostalgia Mania,” a lot of that old stuff has risen from the ashes.

During my porting and flow bench days, I saved and even bought damaged well-ported, big name heads, and saved a couple of my own of various brands to use to verify my flow bench calibration. By obtaining those big name heads I also captured examples of other builders’ fine work.

I kept a record of readouts from those example heads as well as my own work and when I found substantial improvement with a current head I was porting and flowing, I would remove it from the flow bench and flow my baseline test head. If numbers verified, then I would reinstall the current head and see if it repeated the improvement. This was very time consuming but necessary.

The point is, I learned from doing, not by hearsay. Hearsay is usually vague facts, ideas, gossip and wishful dreams passed on. It’s usually exchanged by many and usually distorted, misconstrued and not correct .

That is why, during a trial, you’ll hear legal counselors yell, “Objection! That is hearsay!”

Depending on its gravity, hearsay information can be very dangerous. Here is a classic example. Many years ago, in the early ‘70s, when I was still new in the full-time performance shop business, a young well-read car enthusiast hung around my shop. I liked to call him Fonzie, and he spouted facts about performance engines and cars constantly. Problem was his facts were usually all mixed up.

There were times in my shop where I watched him tell my customers facts about their engines and cars that made no sense. I would have to get my customer aside and clue him in to ignore what Fonzie said. And, when I had a chance alone with the Fonz I tried to dial him in also.

One time, without my knowledge, Fonzie told a guy with a ‘65 Mustang that his 289 was a 271 hp Hi-Po and had Hi-Po rods. The Mustang owner was rebuilding his engine in the backyard, and Fonzie was helping. GULP! The Mustang owner came to my shop, and along with several other engine overhaul parts, bought a package of special SPS rod bolts.

Later, the Mustang guy and the Fonz return and tell me the rod bolts are junk! When they tried to torque the bolts they broke.

The bolts were SPS, but only stock size 5/16˝ to replace the original used 5/16˝ rod bolts for a 225 hp 289. When Fonzie and the Mustang owner showed me the rod, I knew instantly that the 289 was NOT a 271 hp Hi-Po. The back of the package even had the torque specs printed, which gave the 5/16˝ rod bolt torque spec of 19-24 lb./ft.

The Fonz was wrong – imagine that! The Mustang guy was using the Hi-Po rod torque specs of 45 lb./ft. that Fonzie had told him. The Hi-Po rod uses 3/8˝ bolts so they were trying to torque those 5/16˝ bolts twice their proper spec!

I have many other hearsay stories, some of which are even life threatening. That is why I argue that both legal counselors and I deal only in facts.

The Internet is a wonderful tool, but incorrect hearsay information runs rampant. Videos and independent message boards can be the worst, so just be careful.

There are lot of Fonzies out there.