Those familiar with LS engines will often tell you the most frustrating part in the dismantling process is the removal of the harmonic damper.

For some, the process consumes hours. A slow taper is a mighty effective method for locking two components. Medium-duty pullers are apt to break the foot off one leg and pry bars won’t provide an even pull and usually damage the damper rather than remove it. Inconveniently, many modern dampers are not equipped with tapped holes to assist in the removal process. But a new patented tool, the GGT-180 from G & G Technics overcomes the impediments.

Yet, its significance extends beyond quick removal, for this tool is also compact and easy to use. In fact, so modest in size it operates with the radiator in situ. Obviously, this saves draining the coolant, the removal of the radiator and the setting aside of the coolant, to say nothing of the time taken to replace everything. Instead, you simply remove the fan assembly, the drive belt and the harmonic-damper retaining bolt and washer.

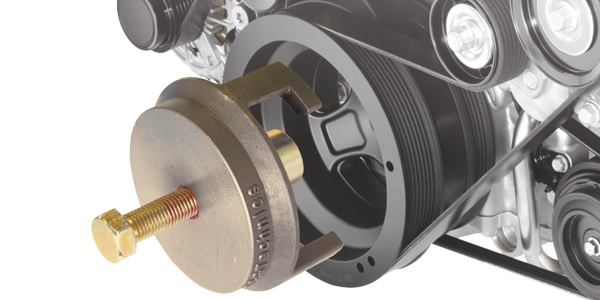

By engaging the puller’s three tangs behind the spokes of the damper—no bolts required—and tightening the jacking screw, the damper is swiftly freed from its bond with the crankshaft.

Notably, the M-16 threaded jacking screw is made from 8.8-grade high tensile steel and is operated by a 24mm socket. The screw rotates within the thrust bearing; its main purpose is to protect the end of the crank. The body of the puller is formed from an investment casting of high-tensile steel and hardened and tempered.

Before use, the manufacturer, G & G, who specializes in the creation of automotive tools, recommends lubricating the screw threads with high grade lithium-based grease. To promote the longevity of the tool’s threaded surfaces they urge operators to avoid the use of an impact gun during damper removal. Lastly, the GGT-180 is now available and priced at $165.00