TURN THE TABLE ON IT

I made a simple turn table using one end of a wooden cable spool, bolted it to a flange, which was welded to a piece of 2 ½ inch pipe. The other end is a 3 inch pipe welded to a plate, making a stand. Slide the smaller pipe into the bigger one for a simple engine stand. The inner pipe must be a little longer than the outer. No need for heavy-duty bearings, the top piece simply rests on the bottom plate, and spins easily.

Bud Belton

Northern Industrial and Automotive

Fairbanks, AK

85 B WITH AAA RESULTS

Here is a way to improve your surface finish from your Block Master 85 B . Just change the upper pulley to a 19-inch pulley. It slows down the tracking and the surface becomes super smooth. You can get the pulley and belt at your local industrial supply house.

Gary Keeling

Keeling Automotive Machine

Santa Clara, CA

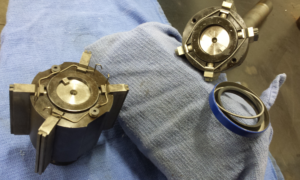

SUNNEN DIAMOND HONE SPRING

Anyone with a Sunnen diamond hone head can gain more clearance on the bottom of the cylinder to main web area by taking off the factory spring setup and replacing it with the spring from a small block Chevy front cover seal. It fits perfectly in the stone slots on the bottom, as shown above in the photo.

Mark Carney

Automotive Machine Inc

Emporia, KS

LESS IS MORE

Many of us who resurface cylinder heads are used to mounting cylinder heads on a milling bar or clamping fixture and then leveling them to the machine. Most modern heads, and some older ones, have the valve cover rail machined parallel with the deck surface. In this case I clamp the heads down to the parallels of the machine.

Because you are eliminating the leveling pivot points, brackets and stud stretchers it produces a much better finish and in most cases you don’t have to do any leveling. If a small amount of leveling is necessary, you can shim one end to get it perfect.

Dave Matton

D and D Auto Machine

Bloomington, MN

PO’ BOY EZ OUTS

Instead of using Easy Outs for removing broken bolts and studs, I use a cut nail. It is tapered, and has enough carbon to be hard enough to grab the bolt.

Its square shape makes it easy to use a wrench to remove. I’ve used these on a variety of bolts and studs with great success.

Bruce Lizzotte

Lake Park Speed and Machine,

Lake Park, FL

MELTED BOOT SOCKET

This worked for me as a fix for removing the melted spark plug boots, as well as the spark plugs on a Honda head. It will work for any other engine with boot melting problems. I modified a spark plug socket with some notches or teeth that will cut through the melted rubber that is left after most of the spark plug boot material is removed. I used a 5/8˝ deep wall socket for this application.

Chris Lines

Auto Supply of Stuart

Stuart, FL