Thanks to my late friend Pete Baldoni, a former NAPA store owner many years ago, I am the proud owner of a genuine Perfect Circle Piston Nurlizing Machine (Note: Perfect Circle spelled knurl with an N). Pete gave me that PC machine years ago, after closing the machine shop part of his NAPA store.

Knurling piston skirts was highly advocated decades ago. I have even done it in emergencies on my Pro Stock and Pro Mod nitrous engines, and with great success. Honoring match race booking contracts is paramount. Sometimes you need to do whatever it takes to do so.

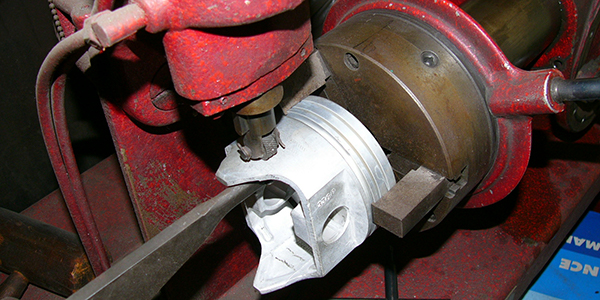

Knurling a piston is the process of rolling a small wheel with a positive sharp design, using adjustable air pressure on the outer piston skirt, with the inside of the skirt on an anvil. This process of rolling the sharp designs on the outer skirt pushes the metal outward around the design, making the skirt diameter larger. As a bonus, the grooves from the image help retain lubrication.

I still put that old PC Nurlizer in use every once in a while. In certain situations it can be a way to save some folks the time and cost of boring.

A recent example is a rare ‘69 classic car with a Ford 351W driven 500 or less miles a year. It has 125K on the odometer. and the engine had never been apart. It is not a race or work car – it is a cruise show car. A general garage engine overhaul is all that was needed.

After ridge reaming, honing a few licks with 220 stone on my Winona Hand Pumper, ball honing the crap out of it with oversized 320 grit, then a few licks with oversize texture brush, the new stock size cast Sealed Power pistons netted an average .005˝ piston-to-wall.

A light 3 pattern knurl brought the piston-to-wall to where I would size it if freshly bored. I then dusted the knurled area with crocus cloth and used Scotch Bright in a solvent tank to ensure no sharp edges.

To verify clearance, besides using mic and dial bore gauge, I drew the piston up cylinder by the wrist pin with long feeler gauges and light oil. The correct size will be when the piston and feeler draw smooth together. This method is as old as dirt. That is how pistons were fitted years ago.

I used file fit moly rings complements of Mat Hartford from Total Seal. The 351W will do fine. I have done this on certain occasions many times for over 50 years. There was an machine shop years ago in a nearby town that knurled every piston, used or new, they put in. That’s where I learned about knurling pistons.

Here is another classic knurling example. I knurled pistons on a 409 to compensate for excessive piston-to-wall clearance with stock bore pistons because no 409 pistons were available.

It was a ‘62 Impala cruise car, which I still see at cruises. No smoke after 25 years and it runs great. I saved the guy from waiting eight weeks to special order expensive pistons.

Now some may poo poo this piston knurling method, but it works for the right applications. Integrity and good judgment are a must. I have been dealing with stock autos, hot rods, and race cars since 1957. I started my mechanic life in 1964 working for garages and several auto dealerships. I have experienced 60 years of judgment on many levels.

There are two different types of knurling – inside knurling and outside. Most engine shops knurled valve guides. It helps for a good while with correct rocker geometry.

But the best guides I ever witnessed were from Gapp and Roush in the late ‘70s. They used bronze-walled original iron head guides. This gave the best of all worlds. A lubricant bronze guide sleeve hard-knurled to the cast iron and then reamed to size. Those held up amazingly well. Even with 5/16˝ stem racing valves. Besides forming a reliable guide, bronze liners can be used to reduce guides to smaller sizes like 3/8˝ to 11/32˝ or 11/32˝ to 5/16˝.

I will talk more extensively about valve guides in my next Fast Lane column.

Some say piston knurling is just a bandage. Perhaps so, but sometimes that’s all that’s needed rather than stitches and/or staples. As I mentioned earlier, knurling requires integrity and judgment to be evaluated.

If knurling pistons is to be done, make sure it is done by someone with experience, and with a good working Perfect Circle Nurlizing Machine. Be sure to practice on a used piston first. Pistons can be cracked if the user is not experienced. The process is not for the faint of heart.