In a spark ignition internal combustion engine, the purpose of advancing the timing of the engine spark is to get past ignition delay. Ignition delay occurs during the time that it takes to fully ignite the mixture with a spark plug. That is typically 15-35 degrees before TDC (top dead center) of the power stroke depending on the engine speed.

Best power is achieved when ignition timing is set to fire the spark ahead of time to reach that peak pressure at about 2 degrees after TDC. This is done with a combination of initial advance, plus centrifugal or electronic controlled advance for engine speed, plus vacuum or electronic advance for engine loading and throttle effect.

Ignition timing trends

As RPM increases, more ignition timing is needed

For higher octane fuels, more timing is needed due to slower flame speed

For large combustion chambers, more ignition timing is needed

For forced induction, less timing is needed because of faster flame speed

For emission controls, less timing is used to reduce smog compounds

For richer fuel mixtures, more timing is needed due to slower flame speed

For alcohol fuels that are run richer than gasoline fuels, more timing is typical

For nitro fuels that are richer than methanol fuels, even more timing is typical.

Ignition Timing Control – Open Loop

For open loop systems commonly used in a carburetor or mechanical fuel injection:

Initial advance – typically 10 to 15 degrees before TDC (top dead center)

Centrifugal advance if so equipped – typically up to 20 degrees before TDC, added with engine speed; more advance with high engine speed

Vacuum advance if so equipped – variable up to 10 degrees, typically; added with engine vacuum; more advance usually at low engine speed.

Electronic limiting of ignition timing is also added for smog control requirements. More recent electronic ignitions modulate spark advance for different driving conditions. This is typical in earlier mechanical fuel injection and lean burn carbureted engines since the late ’60s.

In older engines such as from the ’40s and ’50s, the vacuum advance signal came from the intake manifold. At idle and low speed throttle positions, high manifold vacuum occurred from the closed throttle. At low power levels from a closed down throttle, fuel and air is reduced. The flame speed slows down, so the spark advance was bumped up with a vacuum diaphragm to start the ignition earlier.

In later engines, a vacuum signal was taken from the carburetor that had a different vacuum characteristic, more ideal for emissions. Removing or changing the vacuum signal to a different location in the intake affects drive-ability.

Ignition Timing Control – Closed loop

Timing in more recent ignition systems is computer controlled according to a closed loop ignition timing function. It may be varied for different engine temperatures, throttle positions, and engine loads. A knock sensor can be used to reduce timing when engine knock occurs.

[andoto-embed-video id=”gek3WA2KN7NjL”]

Flame Speeds in Different Fuels

Flame speeds are greater in alcohol fuels than for gasoline fuels in lean, highway fuel mixtures. In one combustion engineering test, methanol flame speed was compared to gasoline flame speed at lean mixtures for each respective fuel. Methanol combustion flame speed was 42% faster than the combustion flame speed in gasoline. Less ignition timing was needed for methanol, however, spark advance in racing is usually greater for methanol than for gasoline.

Mixture enrichment is common for racing alcohol fuels. For rich alcohol mixtures, ignition delay is increased. As a result, usually more ignition timing is needed. The amount of increased timing for alcohol fuels is very dependent on the amount of enrichment.

More enrichment of alcohol fuels usually needs more ignition timing.

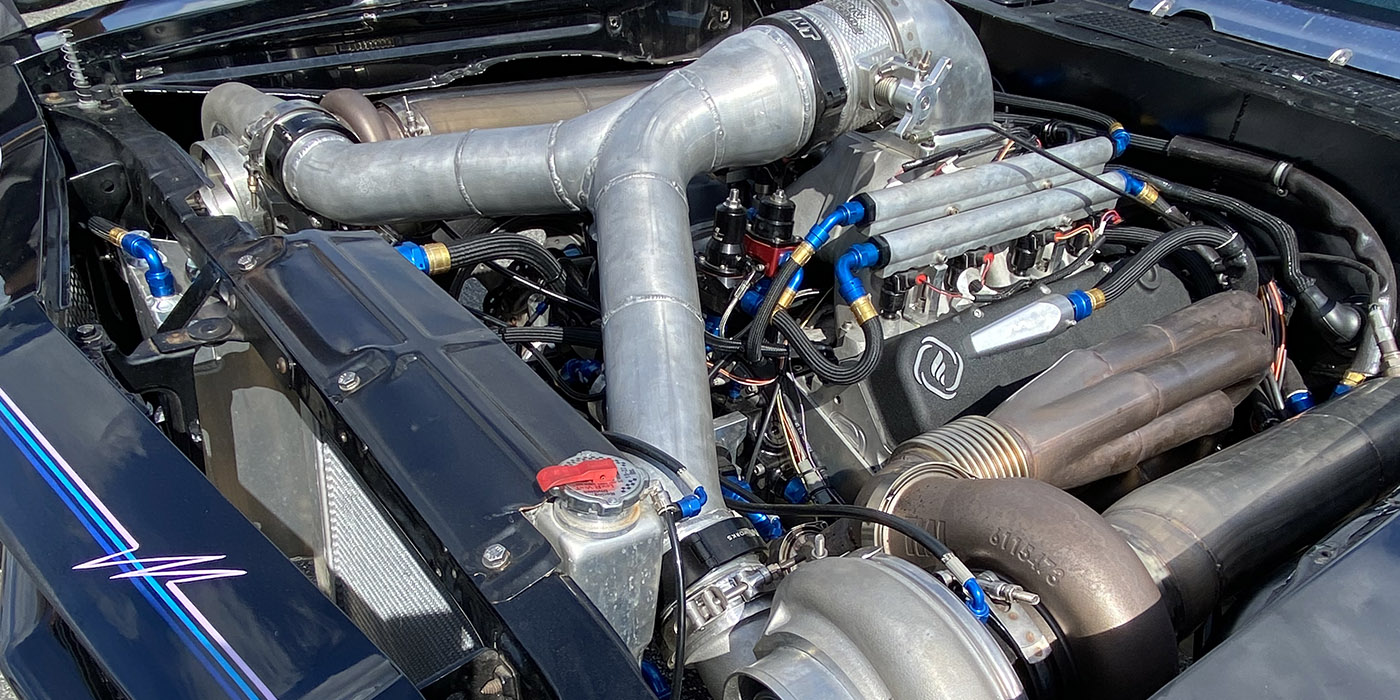

Example: For blown gasoline at around 2 atmospheres, 28 degrees of ignition timing is common for best power. For the same blown engine on alcohol at a richer mixture, 32 degrees of timing is common.

Example: One methanol combustion engineering test measured a 22% reduction in methanol flame speed for a 19% increase in fuel enrichment. An increase in timing was needed for best power.

Less ignition timing is needed for higher power ignition systems. For a blown alcohol engine with an old 2 primary ampere magneto, 38 degrees of timing was common. With a higher power magneto near 4 primary amperes, 36 degrees of timing is common. With a very powerful 44 primary ampere magneto, only 22 degrees of timing is common.

Nitro fuels run a lot more fuel volume and, as a result, need more timing.

Example: For a blown alcohol engine on low percentages of nitro at a low level of enrichment, 40 degrees of timing was typical. On high percentages of nitro at a high level of enrichment, 55 degrees of timing was typical.

Ignition Timing for Fixed Advance (Locked Distributor or Magneto)

Optimum timing from a fixed (locked) ignition advance occurs at only one engine speed. Ignition timing is too advanced at engine speeds below that and not advanced enough at engine speeds above that. Changing the timing value up or down changes the engine speed up or down for the optimum ignition timing. The engine speed operating range affects where the timing is the best. Increasing the timing advance raises the high-end power, reducing the low-end. Decreasing the timing advance raises low-end power, reducing the high-end.

Example: Magneto timing was reduced 6 degrees in our blown alcohol drag racer, and our low-end 60-foot times were quicker by 0.05 seconds from more low-end power. However, the quarter mile ET slowed down by 0.1 seconds, from less high-end power.

Centrifugal Timing Advance

Typically a spark advance of 1 to 1.5 degrees increase per 1,000 RPM is characteristic of an engine demand. Bill Jenkins and Larry Schreib also reported that range of values in their popular Pro Stock drag racing engine-building book The Chevrolet Racing Engine.

Nitro Racing Ignition Timing

Ignition timing is a tuning tool for professional Top Fuel drag race engine builders. The spark advance in a 10,000+ hp nitro-burning engine is typically as follows:

Idle/staging is typically 55 degrees to ignite the cylinders with a rich idle mixture.

Launch typically 50-53 degrees adjusted for an optimum power at launch.

Sudden drop of the timing to typically 36 degrees, approx. 1 second into the run, to instantaneously reduce power for reduced traction from tire growth.

Bring the timing back to typically 50-57 degrees for the remainder of the run to restore power.

Effect of Magneto Polarity

Magneto polarity affects ignition characteristics cylinder-to-cylinder. For the common firing order (1, 8, 4, 3, 6, 5, 7, 2), cylinder set 1, 4, 6, 7 is one polarity. Cylinder set 8, 3, 5, 2 is a different polarity. One polarity has a greater ignition shift than the other. Either set can be set up to the hot polarity. For the same timing, cylinder-to-cylinder, spark plug readings may be different between the two sets without proper fuel system adjustments. Some teams stagger one of the two magnetos, reversing the polarity from that magneto, to achieve both a positive and negative polarity in each cylinder for more consistency.

Bob Szabo is an engineer as well as writer and publisher for racecarbook.com. His website publishes various racing engine technical manuals useful for the engine builder, as well as the customer, to help relieve the engine builder’s customer service burden. Subjects include mechanical fuel injection for racing, alcohol & nitro racing fuels, and tuning drag, sprint, & other racing engines.

Jennifer Szabo is the owner and developer of airdensityonline.com a provider of air density tuning information including current air density, grains of water, and air density forecasts for hundreds of racing facilities around the world. Jennifer is also the owner and developer of the ProCalc fuel injection tuning program.