In the most recent Machine Shop Market Profile study conducted by Engine Builder magazine, readers told us that 22 percent of their production time is spent disassembling and cleaning engine components before the rebuilding process can begin. This is up from 14 percent just three years ago!

Is it any wonder then that 13 percent of our survey respondents indicated they have plans to buy ultrasonic cleaning equipment in the next two years?

Ultrasonic cleaning is one of the ways engine builders can choose to clean parts, but what is it and how does it work? Is it the too-good-to-be-true stuff of science fiction or is it the best technique ever for cleaning the dirtiest of engine components? The truth, as they say, lies somewhere in the middle.

Cleaning With Sound Waves

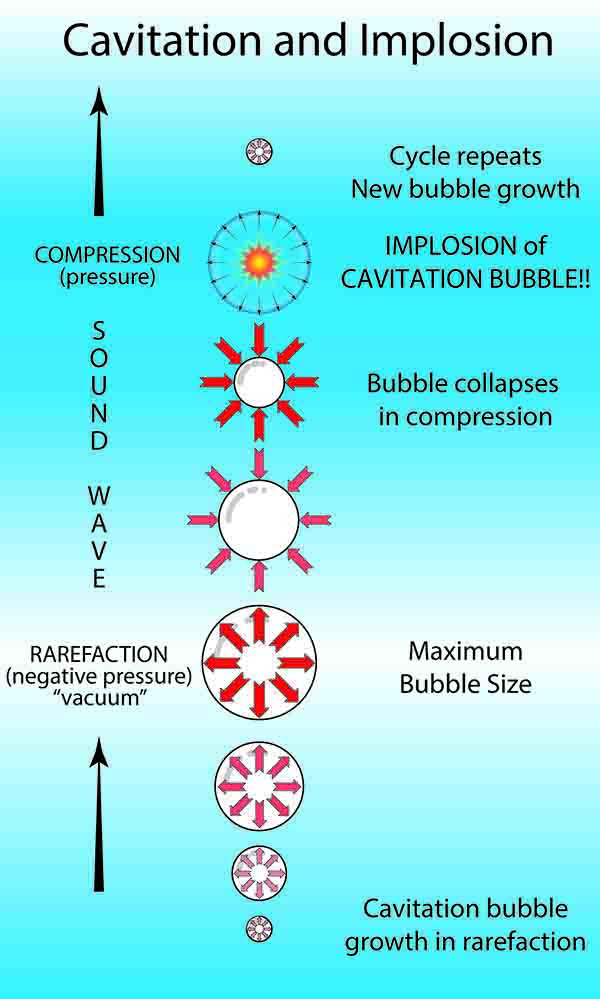

While it may still sound futuristic to children of the ’60s and ’70s, ultrasonic cleaning has a long history of successful cleaning. Ultrasonics is the science of sound waves above the frequency normally considered audible for humans (above 18 Kilohertz). When vibrations at these high frequencies are introduced into liquids, areas of extremely high vacuum and extremely high pressure are generated alternately at any given point in the liquid as the sound waves pass.

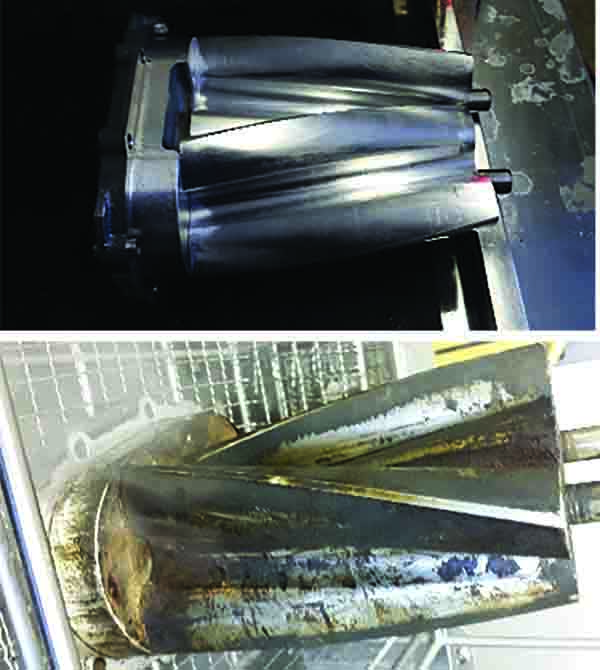

Ultrasonic sound waves have been found to be an effective way to clean many automotive components, especially areas where it is difficult to reach with mechanical devices on complex parts such as automatic transmission parts, aluminum engine components with small oil galleys, blind holes and hidden cavities. Under the influence of a vacuum, the liquid is literally torn apart to create what is called a cavitation bubble. As positive pressure replaces the vacuum, which formed the cavitation bubble, it collapses in implosion resulting in high-pressure shock waves that, in turn, do all the work of scrubbing the component free from contaminants. Ultrasonic cleaning systems work very well on baked-on carbons and oils.

“Ultrasonic cleaning has been around as an industrial process for well over 50 years, says John Fuchs, Blackstone-NEY (www.ctgclean.com/tech-blog). “It was first used in conjunction with vapor degreasing to clean precision components of the day including gyroscopes, aerospace components, etc. As cleanliness became more and more of an issue as automotive technology advanced, there was a natural progression to ultrasonics as a way to get things really, really clean.”

Fuchs says more components have fallen into the “critical cleaning requirement” category over the years. The growth of ultrasonic cleaning in engine rebuilding was fueled in part by its popularity and effectiveness in racing circles. Engine rebuilders saw the benefits, not only of increased cleanliness, but a safer and less labor-intensive process, which was able to clean many assemblies intact without having to break them down into individual components. Ultrasonic manufacturers also started to build ultrasonic cleaning machines that were tailored to the rebuilders at an increasingly affordable price.”

Racing and performance is an apt analogy. “If we think of an ultrasonic cleaner as a ‘power enhancer,’ just like a supercharger, nitrous or a turbo, it actually makes the chemicals being used work better and faster,” says Phil Esz, UltraSonic LLC (www.ultrasonicllc.com). “The cleaning power comes from the cavitation produced by the ultrasonic generator and transducers that attack the parts where we cannot touch, see or feel.

“Technology has really improved how ultrasonics works. Today we’re using more ultrasonic power, mounting the transducers on the side of the tanks versus the bottom, agitation, and better ‘go green’ cleaning chemicals,” Esz says. “Just think of an ultrasonic cleaner as a high-powered stereo system with hot water and ultrasonic soap. The generator (amplifier) produces the power for the transducers (speakers). This combination creates the cavitation or sound wave inside an ultrasonic cleaning tank.”

Using the correct chemical and temperature is also an important part of ultrasonic cleaning, explains Esz. “We have researched many, many brands of cleaning detergents and use a detergent that is specifically designed for ultrasonic cleaning of cast iron and aluminum for the automotive industry. The correct detergent enhances the cavitation in the ultrasonic bath.”

The temperature of the ultrasonic bath is also very critical, according to Esz. “Detergents normally like higher temperatures but the ultrasonic cavitation will start to fade dramatically after 165 degrees F. We have found the best results with temperatures between 150 and 160 degrees F. These results have been observed while using a cavitation meter so we can see what the changes actually make, just like your engine dyno,” he says.

“The customer is often unsure about what cleaner is best suited for a specific dirty project, or what ratio of concentrate to water should be used,” says Rick Schwartz, X2Green Inc. (www.x2green.com). “What’s my cost and what’s right? Depending on the industry and the application, the proper solution may vary, but technical information on machines and chemicals is available on company websites or from technical representatives.”

Schwartz points out that even the latest and greatest technology won’t be as effective if it isn’t used correctly, and that includes choosing the proper chemistry for the system. A good ultrasonic solution is crucial to the system’s effectiveness. Today’s water-based cleaning chemistry is non-hazardous, biodegradable and does a great job removing carbon. It’s safe for the worker, environmentally compliant and is extremely effective.

Machine and chemistry suppliers say that proper solution selection means that most surfaces can be cleaned effectively. Burned-on carbon remains a difficult contaminant, especially on aluminum substrates, but chemical manufacturers are making progress in this area with a new generation of chemical formulations, Fuchs says.

“The majority of applications use water-based solutions with a detergent containing surfactants and other additives depending on the application,” he says. “There are many formulations that have been developed specifically for use in engine rebuilding and the life of the chemistry is directly related to use. In some applications, chemistry may last for several weeks, while in others more frequent replacement is necessary.”

In the typical shop, cleaning choices are often driven by budget and throughput, and range from hand washing to automated cleaning systems. Moving to a device as simple as a single ultrasonic cleaning tank followed by rinsing can improve cleaning results and productivity, allowing more parts to be cleaned at a time while personnel are freed to perform other tasks, according to experts.

In addition, ultrasonics can accomplish cleaning that can’t be achieved using other technologies, so its value is significant. While ultrasonic cleaning shouldn’t be considered “cheap,” Fuchs points out that in most cases the ease and quality of cleaning from the use of ultrasonics make it worth the investment.

Esz says that the claims and expectations of ultrasonics cleaning all carbon from pistons and cylinder heads to make parts look like new are simply unrealistic. “Ultrasonic cleaning has limitations just like any other machine in your shop. With burned-on, real gooey carbon, heavy carbon, grease, and any substance that is soft, an ultrasonic cleaner can also struggle to clean.

“We have found some simple solutions: Pre-clean the parts in a spray washer for 5 minutes or less getting the heavy soils off the parts. Then, after doing so, ultrasonic clean for 5 minutes and inspect the part. If there are heavy soils left on the part we can scratch 80% of heavy soil off and ultrasonic clean for another 5 minutes or pre-soak the parts in the ultrasonic tank for a couple hours or even overnight allowing the detergent to loosen up the heavy soil. We do not recommend running the machine longer than 15-minute cycle times with ultrasonic cleaning because this can cause etching on the parts. Etchings are those little squiggly marks left on the milled surfaces of the part,” Esz says.

According to Fuchs, ultrasonic cleaning systems are usually self-contained and simply plug into a power source. There will also need to be a supply of water available for filling the system and a drain or collection tank for disposing of the spent chemical. Many users elect to have a service (like Safety-Kleen) manage disposal issues as regulations can be difficult to negotiate. Systems with filters (used to extend the life of cleaning chemicals) require filter replacement, but other than that, they are relatively maintenance-free.

Today, cleaning engine parts – whether they are small parts like fittings and fasteners, bigger parts like connecting rods and pistons, or even cylinder heads on up to engine blocks – requires attention to the three Es: economics, efficiency and environmental awareness. According to our experts, ultrasonic cleaning can be a profit center of cleaner parts, another step towards insurance of no engine failures, and creates new forms of revenue.