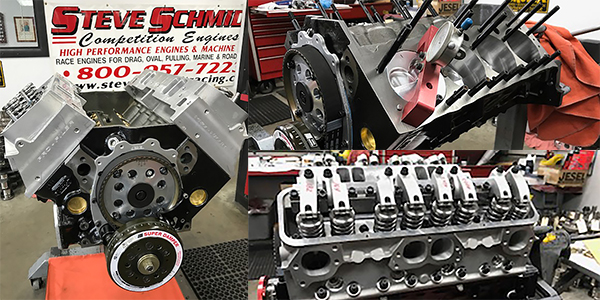

Steve Schmidt is a busy guy. He runs Steve Schmidt Racing Engines in Indianapolis, a 28,000 sq.-ft. engine shop capable of producing 700 engines a year, with two full machine shops and a dyno.

Steve Schmidt Racing Engines (SSRE) has been in business for 40 years. Steve himself got into the industry due to the hot rod and muscle car craze of the ‘60s and he’s been invested ever since.

“Getting into engine building was just a natural progression,” Schmidt says. “I got interested in cars and I got interested in racing cars and I drag raced for about 45 years. As I started doing engines and setting national records, I started doing engines for other people and it just evolved and kept growing and kept growing. Then we raced professionally for 12 years in NHRA Pro Stock. It’s now grown to where we work on – between OEM engines and racing engines – approximately 700 engines a year.”

SSRE’s two machine shops are necessary to split up the huge amount of engine work coming through the shop. One machine shop is primarily for OEM engines and the other machine shop is primarily for racing engines. However, Schmidt says the shop has no limits when it comes to the engines it can work on.

“We work on every kind of engine there is, no limits – automotive, marine, industrial, racing,” he says. “The bulk of our racing engines are for drag racing, truck pulling and marine. Although we dabble in other kinds as well, such as road race engines.”

It’s actually quite incredible that Steve is able to keep tabs on the engines going in and out of the shop these days. Just recently, Steve did a 465 small block Chevy engine for a new customer who was referred to SSRE.

“It’s a brand new engine build,” he says. “We started with an iron Eagle block and then we cam bored it for a 55mm roller bearing camshaft. We lifter bush it for a .937˝ lifter. We also do all the rest of the normal machine work – bore, block true, deck and finish hone it. We use Rottler and Sunnen machines.”

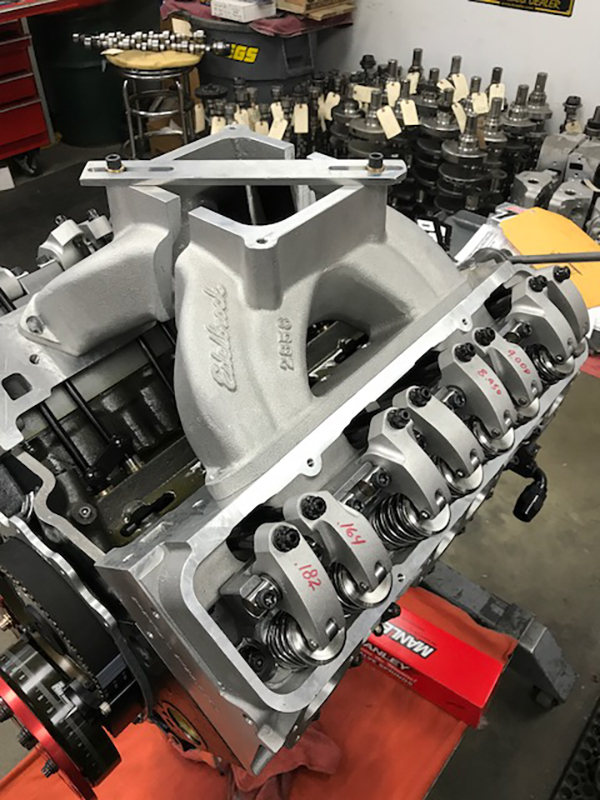

The 465 cid SBC engine has a laundry list of parts featured throughout it such as a Callies Magnum crank, Oliver Racing connecting rods, CP pistons, a COMP Cams camshaft, a Jesel belt drive and rocker arms, Manton pushrods, Clevite bearings, and Total Seal piston rings.

“The heads are a 13-degree profile that we CNC’d in-house and then hand finished,” Schmidt says. “The most important thing in the build is an Edelbrock Spyder intake that we cut in two, [weld back together] and section to fit on the taller deck block. That does two things – increases the plenum volume for the bigger, cubic-inch engine and maintains the tune length by not using spacers on the intake and making the intake manifold longer. That’s a crucial part.”

Thanks to clever machine work like that and 40 years of engine building experience, this 465 cid small block Chevy should crank out roughly 925 hp with a compression ratio of 15:1. Look for it on the drag strip!

The Engine of the Week eNewsletter is sponsored by Cometic Gasket.

If you have an engine you would like to highlight in this series, please email Engine Builder magazine’s managing editor, Greg Jones at [email protected].