“Aerodynamics are for people who can’t build engines” – Enzo Ferrari.

That quote is at the bottom of Brandi Anderson’s email signature. She and her husband Howard own and operate AR Fabrication in Winchester, VA, and the pair can certainly build engines.

Howard started in this industry in 1997 building cars for himself. He officially started AR Fabrication in 2000 as a shop focused on chassis fabrication, dyno tuning and engine assembly.

“We had lead times extending past 8-10 months from the West Coast to the East Coast,” Anderson says. “After dealing with this for a few years, we decided it was time to purchase our own equipment to start machining the engines in-house. We now specifically focus on engine machining and assembly. We are a full machine shop, and currently are almost 100% in-house with all processes we offer to clients.”

Brandi started working at AR Fabrication in October 2006 as the office manager.

“As the business has changed and grown, she has become the cylinder head specialist, as well as the other main point of contact in the shop,” he says. “Chances are, when you call in, you’ll deal mainly with her, unless you have some technical questions she can’t answer.”

Howard manages the business and performs the majority of the block machining, with the exception of cylinder honing. The shop also has two other employees – Josh and Tony.

“Josh started working with us in March 2017,” Anderson says. “He has learned a lot in the last year, and is now the main short block assembler. He also performs all the cylinder honing and balancing.

“We also have Tony, who is the cleaning specialist. This is a very important job, because most engine failures are a result of unclean components. He’s retired but works a full 40-hour week. He is very detail oriented and it shows in his work.”

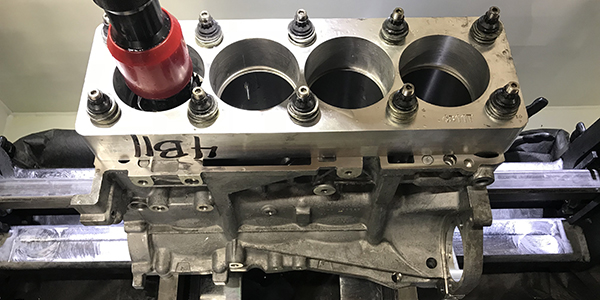

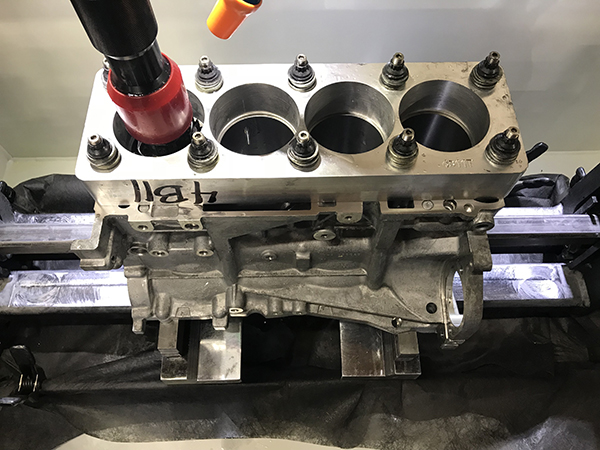

In addition to all the work AR Fabrication does, the shop is also a sleeving center for Darton Sleeves, which is how the Andersons got their hands on their first Mitsubishi 4B11 Evo engine.

“The first 4B11 came into our shop for a set of Darton MID sleeves,” Anderson says. “Since then, many 4B11 blocks have made their way through our shop. The OEM sleeves are prone to cracking at higher boost levels or piston failures due to improper tuning.”

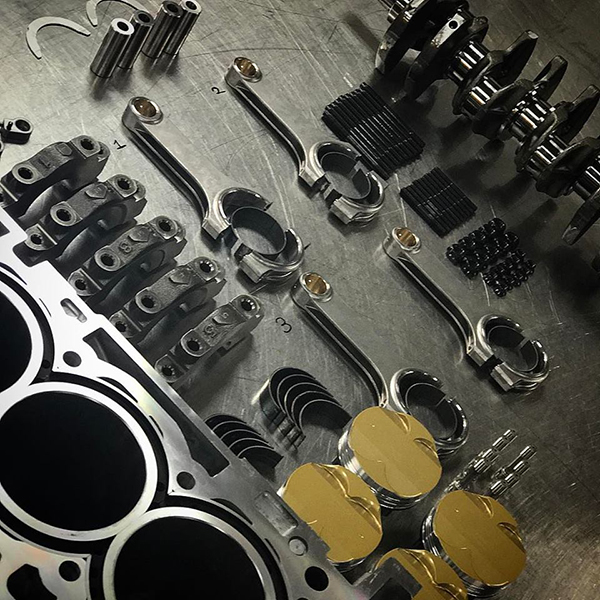

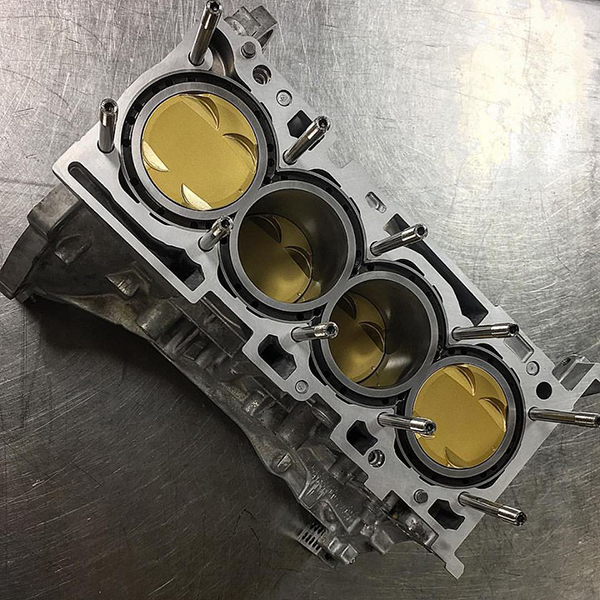

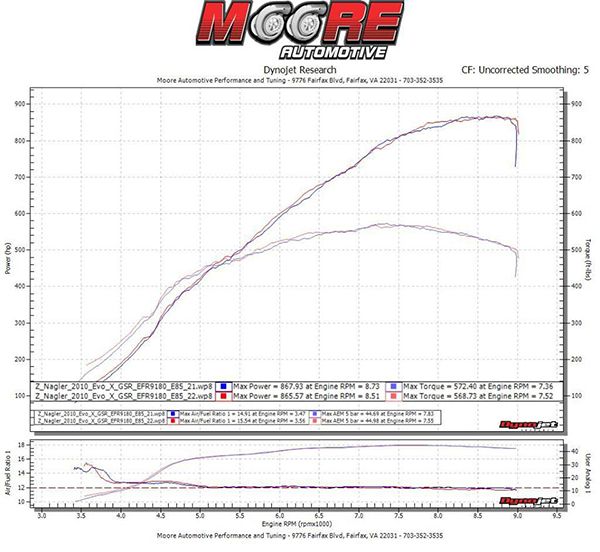

This particular 4B11 Evo engine was built for Moore Automotive in Fairfax, VA. AR Fabrication did some head reconditioning and porting, block sleeving, boring, honing, and engine assembly services for this build.

“We build for several shops that have their own specifications,” Anderson says. “When we offer our specification, we prefer to use Diamond pistons, Manley rods and crankshafts, Total Seal rings, ACL bearings, Ferrea or GSC valve train, always Cometic head gaskets, and lots of Calico coatings.”

The shop makes use of a Haas VF-3, a Rottler CNC cylinder hone, a SERDI 3.5, UltraSonic cleaning and T&S Precision Balancing for the engine work it performs.

“We have done so many of these over the years that we have learned all of the snags that could happen, and take the necessary precautions to ensure these don’t happen,” he says.

Most of the engines AR Fabrication builds go to reputable engine tuners, so Anderson works closely with these shops during the break-in procedures.

“Each short block we build comes with a specific break-in procedure that must be followed to ensure the success of the build,” he says.

This 4B11 engine went in a Mitsubishi Lancer Evolution X, and after all of the work AR Fabrication did, the car made 867 whp and 572 lb.-ft. of torque. On to the next one!

The Engine of the Week eNewsletter is sponsored by Cometic Gasket.

If you have an engine you would like to highlight in this series, please email Engine Builder magazine’s managing editor, Greg Jones at [email protected].