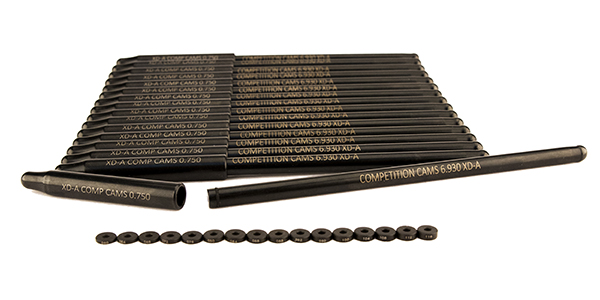

COMP Cams has introduced a game-changing method for accurately setting lash or pre-load while using non-adjustable-style rockers. The patent-pending XD-A Adjustable Pushrods incorporate a top section that slides two inches inside a wider bottom section, with one or two shims captured in-between.

These pushrods won the Best New Performance – Racing Product Award during the 2016 SEMA Show. They are currently available for GM LS engines with more popular applications coming soon. Proven to 9,000-plus rpm in solid roller LS applications, the system provides a 90-percent increase in bending stiffness for enhanced valve train stability.

It also allows for lightening of a rocker arm system by 30-plus grams on the backside, by removing the adjuster and required support area for threads and seating. The use of lighter rockers (such as the COMP Cams SPR Radius Tip Rocker Arms) with XD-A Adjustable Pushrods allows higher RPM to be achieved by creating a much more dynamically stable valve train system.

The pushrods are designed especially for engines with low-mass rocker arms and a light valve train, with drop-in fitment in LS engines. They can be adjusted over a range of .172˝ in .004˝ increments with shims, sold in sets of 16 by thickness or as a 240-piece set containing all available thickness options. Top sections are available in 0/200˝ increments for coarse adjustment. The pushrods work with hydraulic and solid roller camshafts.