Thanks to spending his youth hanging around his uncles, Jan Norris grew up in machine shops. And if you ask him, he hasn’t worked a day in his life. Building engines is what he loves to do. Now 68 years young, Jan has owned Precision Engine Machine Co. in Hyattsville, MD since 1979 and builds all sorts of engines along with his son Michael, 48, grandson Branden, 25, and three other employees.

“I have no intentions of retiring until I fall over dead in front of one of these engines,” Jan Norris says. “However, what I am trying to do is transition Michael into running the entire shop. He’s bringing us up into the modern day.”

Precision Engine Machine Co. was founded in 1967 by Bill Ford and Dick Burgess. Jan joined the team as a machinist soon after and bought the shop from Bill and Dick in ‘79. When the shop started in the ‘60s, it was partially funded by Bruce Wheeler, a local businessman and owner of a Top Fuel Dragster car named Wheeler Dealer. The shop built the engine for the Top Fuel car, which ended up going to the nationals and finishing runner-up in the finals to ‘Big Daddy’ Don Garlits.

“We got a lot of recognition from that because we were a no name outfit in Hyattsville, MD and had made it to the finals,” Jan says. “So we got a lot of work, and after that we got Lee Edwards and Gene Altizer – all those early racers would come to us with their stuff.

“Then, towards the end of the ‘70s into the ‘80s, I took us into the NASCAR stuff. We did that for a long time. We also did offshore boat racing, tractor pulling, Corvettes and Ferraris for 24-hour racing – I guess over the years I’ve done a little bit of everything.”

In ’95, Jan was doing a lot of NASCAR engine work and suffered a heart attack that year. He recovered, but doctors told him he needed to crank it back a bit.

“After that, I moved to the building we’re in now and told my son Michael and grandson Branden that I was only going to do whatever walked in the door,” he says.“When I started in this business, I apprenticed under an old German machinist, and his rule was whatever comes in the door we do and that’s sort of how the old time machine shops were. I wanted to go back to that.”

Today, the machine shop will take on street rod motors, performance engines, tractor pulling engines and marine engines – since the shop is located within spitting distance of the Chesapeake Bay.

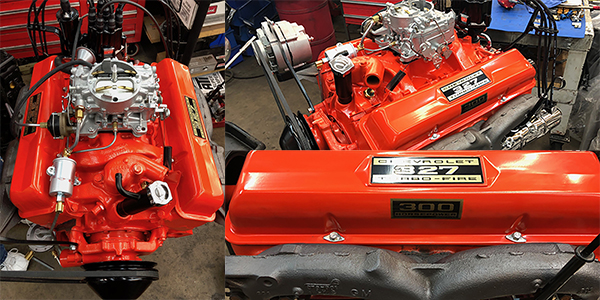

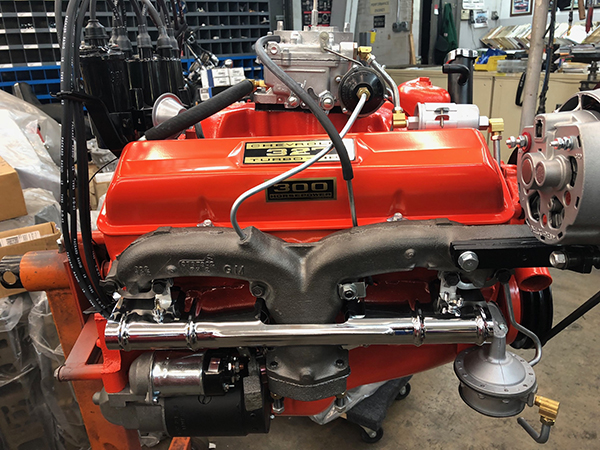

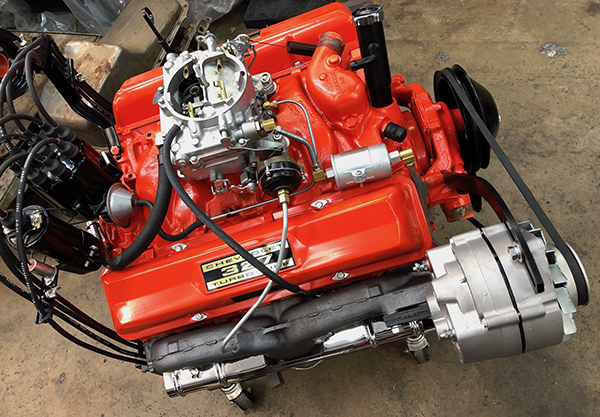

As a full machine shop with the capability of doing all work in-house, Precision Engine Machine has the ability to work on any engine that crosses the shop’s path. Recently, Precision Engine Machine had a customer come to them wanting to rebuild a 327 cid Corvette engine. The rebuild fell on the shoulders of Michael Norris, but it turned out to be more than a ‘simple’ rebuild. The customer wanted a numbers-matching 327 Corvette engine for a ’63 split window coupe Corvette that met the National Corvette Restorer’s Society (NCRS) guidelines.

“Our customer was doing a frame-off restoration and he wanted everything absolutely numbers matching for the engine build,” Michael says. “Every date code and casting number has to be correct. The color of every external piece has to match the factory. Every bolt head has special markings. Even the spark plug wires have a date on them. At the beginning of this build I wasn’t up on all the NCRS judging rules and everything. I actually joined NCRS, got a judges book and went through that book on every single piece that had to do with the engine and made sure that everything that we were doing met all of the judging guidelines for this 1963 Corvette.”

To start the build, Michael had to make sure the block was reusable, as it was the only piece of the original engine that was still numbers matching when the customer brought it into the shop. The block is an OE GM factory 327 cid numbers matching block with Casting Number 3782870 and Date Code L172.

“With that old of an engine, the first thing that we did was make sure the block was good – hot tanking it and magnafluxing it to make sure everything was good there,” Michael says. “We did a full array of machine work on the block – checking the align hone and boring it .040˝ over. On this particular engine, we needed to deck it, but preserve the stampings on the front of the block, which is a little bit tricky to make sure that we weren’t destroying the serial numbers on the front of the block. We fully machined every surface. The block also had to have two sleeves installed.”

The next thing that Norris had to do was make sure the heads and the intake manifold going on the engine were both date coded and the correct casting numbers for that engine.

“I began to search for some head cores that would match that engine with the correct date code,” he says. “The car was built in January 1963, so what I ended up doing was finding cylinder heads and an intake manifold that were cast within three months of that date, so that it would match with the actual date of the build of the car.

“That was a matter of going and searching multiple Corvette groups and eBay, and I actually ended up buying two separate cores off of eBay and completely redoing the cylinder heads with new guides, new exhaust seats and new Manley stainless steel valves and springs. One thing we did that wasn’t factory was we put in Manley screw-in studs and guide plates because some of the studs were actually pulling out of the heads. The heads have Casting Number 3782461 and Date Code L102.”

All-in-all, Norris had to hunt down every single part he could find because most of the engine came to the shop in a basket. However, for a guy who’s been in an engine shop since the age of 4, this engine build was a fun, new challenge.

“The hardest part was doing all the research and finding the parts, but that was also the most fun part,” he says. “I’ve built I don’t know how many Gen 1 small block Chevys over the years, but this was by far the most fun one that I did because I got to learn so much about how the factory built these things back in ‘63 and all the little intricate details it takes to build a NCRS judgeable car.”

On the exterior, the 327 Corvette engine looks completely factory. But on the inside, Precision Engine Machine did use some upgraded, aftermarket parts. Norris says those parts don’t take anything away from the value of the car once the overall build is complete.

“Overall, this build cost more than $16,000, mostly because of the cost of sourcing the correct parts,” he says. “The crankshaft is an original GM factory 327 small journal crankshaft. We magnafluxed it for cracks, ground it .010˝ under on both the mains and rods and balanced it. We also nose drilled for the harmonic balancer bolt as a safety concern since the crankshafts were not drilled in 1963.”

The only other parts on the exterior of the engine that were factory are the 327 oil pan and the alternator/distributor, which was sourced from Corvette Stop in California.

“I had a NCRS alternator built for it that had the date codes down to the diodes on the alternator matching the car,” Michael says.

Some of the aftermarket parts used on this 327 Corvette engine were Eagle ES rods, Speed Pro forged pistons, Total Seal rings, a COMP Cams camshaft, hydraulic flat tappet lifters and valve springs, Clevite rod and main bearings, Manley stainless intake and exhaust valves, and a Melling oil pump.

“The engine came out looking absolutely beautiful and should put out around 300 horsepower,” he says. “The total build time on this was about 18 months and most of that was searching for parts, doing research and figuring out exactly what we needed to get.”

Now that the 327 Corvette engine is complete, the rebuilt ’63 power plant will have to spend a little time in storage until the car restoration is at a point where it’s ready for the engine.

The Engine of the Week eNewsletter is sponsored by Cometic Gasket and Penn Grade Motor Oil.

If you have an engine you would like to highlight in this series, please email Engine Builder magazine’s managing editor, Greg Jones at [email protected].