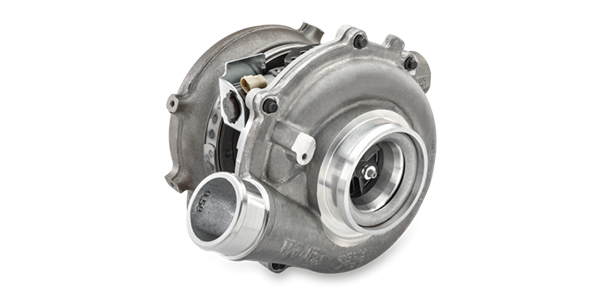

PurePower Technologies, an engineer and remanufacturer of air and fuel management components for OEMs and the aftermarket, has launched a 6.6L diesel turbo designed specifically for the aftermarket.

PurePower offers assembly, remanufacturing and 100 percent end-of-line testing for high-volume, high quality turbos for light-, medium- and heavy-duty diesel truck engines, having recently invested significant capital in reman turbo production capabilities.

“The launch of the 6.6L diesel reman turbo expands our turbo platform across new high-volume makes and models,” said Jerry Sweetland, president and CEO, PurePower Technologies. “We will deliver only the highest quality turbos to the aftermarket by leveraging our OE heritage in single-digit PPM remanufacturing processes.”

PurePower also has the capacity to independently remanufacture turbos using a modular approach for an assortment of all makes wastegate and variable geometry turbochargers with its expanded automated error-proof, high-volume assembly operation.

With its precision hot gas stand testing, real-world validation on heavy-duty engine dynamometer cells, precision component machining and assembly capabilities, PurePower manufacturers turbos which meet or exceed OE standards.

Certified to TS 16949, PurePower’s rigorous quality assurance standards and processes allows it to develop products that stay ahead of market and regulatory trends, and deliver uncompromising quality, durability and fuel economy.

For more information: purepowertechnologies.com/turbos.