Sourcing Rotating Assemblies for Stroker Applications

Stroker engines are a popular choice for performance enthusiasts – whether the vehicle will run on the street, strip or a little of both, there’s something for everyone to love about a stroked engine. First of all, it sounds cool. Customers love telling their friends that they have something no one else has; a stroker motor from YOUR SHOP.

Selecting the right package for your customer is the first discussion you need to have after you talk budget. Are you going to need to clearance the block, crankshaft or rod bolts? Once you have the block figured out, you may have the choice of using off-the-shelf parts, or you may need to do some machining to make it all fit without hitting anything.

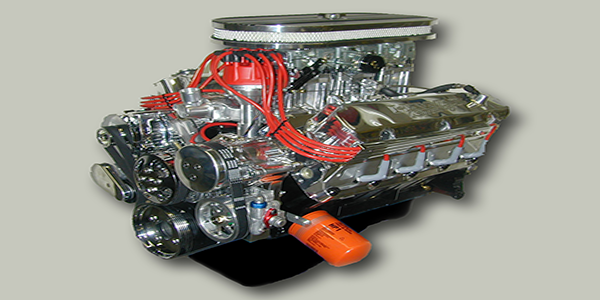

A typical, complete stroker kit is made up of the crankshaft, connecting rods, pistons, piston pins, main bearings, rod bearings and piston rings. Many different types of each of the components can be used for different applications.

Crankshafts may be either forged or cast. Rods may be I-beam or H-beam style and made of various materials from steel to aluminum and even titanium if your customer can afford it. If you use the stock length rod, you will need either shorter pistons or a taller block. Going with shorter rods means you can use stock height pistons so they won’t pop out of the top of the block. Smokey Yunick famously said to “stick the longest rod possible in it,” but that philosophy is changing. We won’t get into rod ratios here.

Aftermarket manufacturers are going all-in on the stroker game. Scat, Callies, Eagle and others offer stroker kits (some of which you can find in our handy Engine Builder Stroker Resource Guide – charts of complete rotating assemblies are available online at EngineBuilderMag.com). The selection of components often comes down to cost and how much budget your customer has to work with. Stroker kits can be a great way to go if you want everything in one, no-fuss package. All you’ll really need to do is prep the block for whatever clearance you need and bolt-in the new parts.

Some engines lend themselves to stroker builds like SBC and BBC as well as the LS engines because there are a plethora of parts available, but just about any engine can be stroked. Where there’s a will there’s a way.

“Modifying the LS for more power is as easy as falling off a log,” says Engine Builder contributor Len Emanuelson. He says there are a few issues to overcome, especially if you are building a high-rpm race engine, but for the milder versions, the LS responds nicely to boring and stroking and improved cylinder head flow. They respond especially well to power adders.

Most companies selling stroker kits do a nice job of listing compatible heads with their kits. But you must know what you’re trying to achieve and the basic package you’re going to be working with. Be sure to take some time to research a combination that will work for your customer and consult your parts vendor.

Callies

Callies offers the Ultra XD connecting rod for stroker applications. This configuration is designed for extra cam-to-rod clearance in long-stroke small block Chevy race engines. In most cases, the XD connecting rod will provide .050˝ more cam clearance than the company’s conventional Ultras, and substantially more than many other connecting rods.

Callies will also pair your crankshaft with fully balanced and ready-to-assemble rotating components to not only save you time and money, but provide the peace of mind that your components are matched for compatibility, giving you a trouble-free project.

Due to the vast offerings of parts and individual needs, no two Speed Packs are the same. Finding the right combination of parts for your specific needs comes down to a good consult with your parts vendor. All you have to do is give them the desired cubic inches, compression ratio, cc of the cylinder heads, final bore and deck height and Callies will build the kit for you.

Scat

Scat is one of the pioneers in the performance industry and has continually evolved their offerings over the years to fit the market. To that end, the company has a full line of ready-to-go stroker rotating assemblies that they call their Scat Pack.

The company’s website claims it has more than 1,200 stroker combinations available of off-the-shelf components, which includes everything from soup to nuts as well as the pistons, rings, bearings and the option to balance it. If you allow Scat to balance everything, it makes the process even easier, so it’s basically a bolt-in modification after the block is prepped.

You should also double check all the parts before installing, of course, but Scat offers a full line of these in multiple variations from SBC to LS to Mod motor and Coyote, as well as Hemi applications.

Eagle

Eagle offers more than 1,900 new rotating assembly combinations for everything from Subaru, Toyota and Mitsubishi to Ford FE, Oldsmobile and all the GM variants. The company’s line of kits also includes new Pro Street kits featuring forged 4140 steel crank, FSI 4340 steel I-beam rods, and a variety of pistons. Eagle’s website and 2018 catalog list all the combinations along with a little explanation about stroker philosophy in general:

Almost never is increasing the breathing capacity a bad thing. The limitations of an engine are more to do with the engine block and other factors. Making more power is not only about increasing the breathing capacity, there are other things to take into account like camshaft specs, head flow and more. Without getting too detailed, you need to understand that not all components that work well for a 302 cubic inch engine work best for a 331 cubic inch engine or a 347, or a 354, etc.

Here is a handy formula used for finding the engine size of an engine:

engine size = bore x bore x stroke x 6.2838

You might think that increasing the bore would have more of an effect than increasing the stroke if you wanted to increase the engine size. You would be right except for one problem: You can’t make huge increases in bore size because the block usually won’t allow it. For example, most small block Ford blocks can only be bored .060” oversized (4.060” vs. a stock size of 4.000”). It is quite easy to increase the stroke by .400” (from 3.000” to 3.400”). In addition, if a block is bored to the limit, it cannot be bored again after that! Most people will want to save a little room for “freshen ups” or rebuilds.

Wiseco/K1

K1 and Wiseco have teamed up to design rotating assembly components around each other from the inception to enhance the strength and eliminate mass. Engine builders will note the assembly balances well and fitment requires much less finish and balancing work. All of the rotating assemblies come with pistons that are 100% forged and manufactured in the USA to withstand the heavy use of a professional racer or the more general use of a weekend racer.

These assemblies also have multiple choices of crankshaft and connecting rod offerings from K1. All components sold by K1 are either forged or billet steel, depending on your choice in assembly. Either way, you will get a rock-solid bottom end that matches very well with Wiseco forged pistons.

WDs

If you look through our Stroker Resurce Guide, you’ll see a wide assortment of stroker kits available from national warehouse distributors. These distributors are a good source of stroker kits and can mix and match brands that some of the other manufacturers do not. They also offer some very affordable house brand options in some cases.

One of the distributors we spoke to said that kits are the way most engine builders are ordering these days. It’s like ordering combo meal #1 from your favorite fast food joint. Most of the combinations are set up like that for a reason, because the majority of the time people were ordering those combinations to begin with.

The process has been simplified to where we are with stroker kits today. You want a 632 cid big block kit? No problem. Do you want fries with that shake?

If you’re building a high-end race engine, you may take a little more time in piecing your combination together. And the same may be the case with a more obscure engine that is difficult to find parts for in the aftermarket. The point is that a stroker kit can be what you want it to be. With parts vendors offering so many choices ready-to-go out-of-the-box, why not take advantage of it and sell some more stroker engines? Your customers – and your bottom line – will thank you for it!