For Dean Yatchyshyn, engine building became intriguing when he went to work for Volkswagen Garage Engine and Transmission Repair in 1973. It was shortly thereafter that he bought a 1970 Chevelle with a 454 in it. According to Yatchyshyn, his interest in engine building took off from there. And who can blame him?

“I was bit with the internal combustion engine bug,” Yatchyshyn says. “I still have the car today. It’s sitting right here in the shop.”

That started it all off. From there, Yatchyshyn began managing a speed shop for five or six years and convinced the two brothers who owned it to start their own machine shop.

“Because we were out here in the sticks, we didn’t have anybody to do performance work and we were hauling stuff two and a half hours to the DC area,” he says. “So they bought some equipment and I knew how to run it and started their shop. In 1982, I went out on my own.”

Going out on his own meant a 28’ x 32’ garage space for a few years, until about 26-27 years ago when Yatchyshyn bought a 9,000 square-foot building in downtown Cumberland, MD and renovated it into what is now Cresap Automotive Machine.

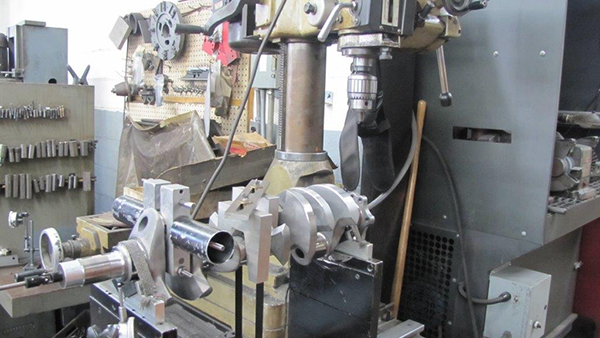

“From there, I slowly started building a business, a little bit at a time,” he says. “I constantly reinvest in the business – I had the first flywheel grinder in this town. I had the first pressure test bench for cylinder heads. I had the first boring machine that lined up off the crankshaft centerline. A CV616 cylinder hone so we could do our cylinders in a professional manner. I kept reinvesting into the business.”

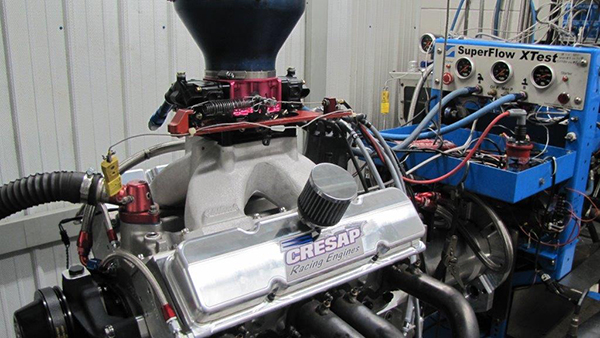

Today, Cresap Automotive Machine is a full machine shop capable of doing everything in house with the exception of welding crankshafts. The shop has a crankshaft grinder, a crankshaft magnafluxer, a surface grinder for cylinder heads, an align boring machine, and an in-house dyno.

“About two years ago, I could see the industry was going to get a little bit lean, so I put two CNC machines in – a vertical VF5 Haas and a ST10 lathe – and we started doing industrial work,” he says. “That’s expanded our customer base to wherever UPS will deliver.”

Yatchyshyn recently did a plate for a tensile tester for a company out of Washington state and gears for an orange juice squeezer for a company in Sebring, FL.

While that kind of extra work has helped Cresap bring in more dollars, the engine work is still the primary focus, and the shop specializes in high performance work.

“We don’t have a true, one-make, one-model clientele,” Yatchyshyn says. “We work on the full gamut of engines. We don’t have the luxury of just picking and choosing what we can do. We have to do whatever comes in the door if we can make a buck at it.”

Just before the recession, Cresap concentrated pretty heavily on dirt track engines until that market went away in the Maryland area around 2008 when the local track closed, money tightened up and the economy went south.

Yatchyshyn made sure that Cresap branched out. The shop moved into some drag racing motors as well as marine engines such as jet boats, in-boards and some power heads. The shop will also do the small stuff – four wheelers, dirt bikes, boring cylinders and resleeving cylinders.

“When I put the dyno in, I also bought a Serdi machine so we can do down to a 4 mm valve stem for valve jobs on these little motorcycles,” he says. “Even some of the cars are coming with these small valves. If you don’t have modern equipment, you’re not going to be able to work on them. The old stone bench just isn’t going to get it.”

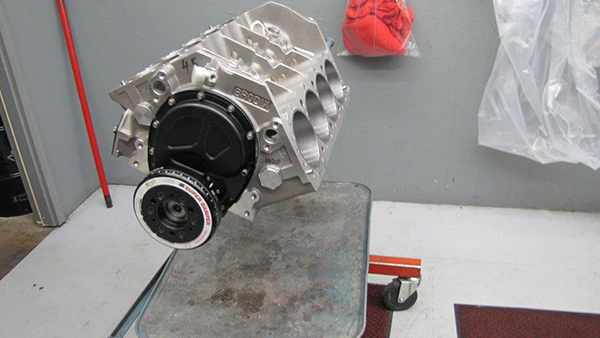

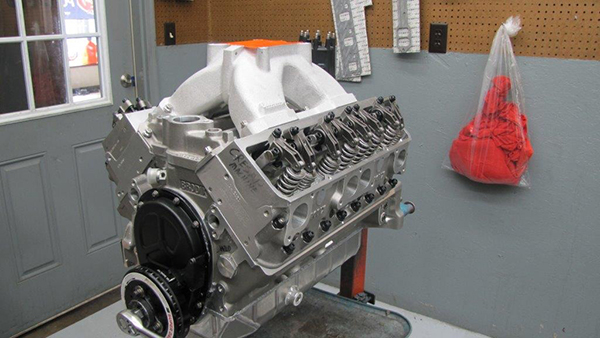

With Cresap being a well-diversified machine shop, Yatchyshyn says they’re not working on your run-of-the-mill 350 Chevys. Recently, the shop finished up an all aluminum, dirt, super-late-model motor.

“The engine is a 438 cubic inch small block Chevrolet-based, dirt, super-late model engine, but it’s the newer version,” Yatchyshyn says. “The old small block was on a 4.400˝ bore spacing center-to-center on the holes. Everybody wanted a bigger cubic inch, but they wanted a lightweight small block. So the manufacturers came up with a wide bore spacing. They went to 4.500˝ spacing between the cylinders and that opened up a whole new avenue of cubic inches.”

This engine is for a repeat customer who Yatchyshyn did work for five or six years ago. The customer returned to Cresap wanting a new motor.

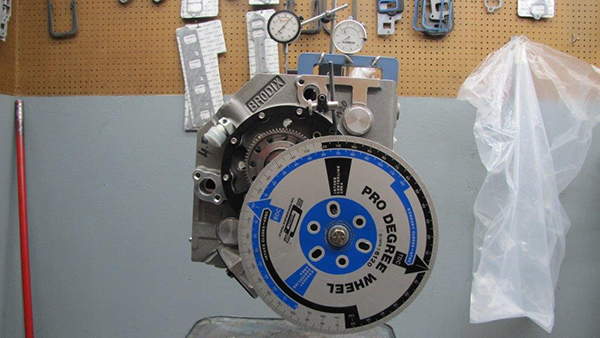

“As technology has moved forward, we decided to go with the new 4.500˝ bore spacing with that cubic inch, 11-degree cylinder heads, solid roller camshaft and all the bells and whistles that go with that type of motor,” he says. “Every nut and bolt on it will be brand new.”

According to Yatchyshyn, the block comes in pretty much finished up. However, the shop will bore the cylinders, deck plate hone them, cut the deck to the proper height for the piston configuration and the bore and stroke, and finish the line bore on it to their specifications.

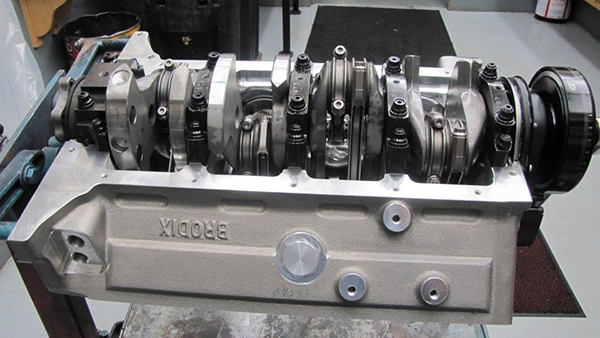

The crankshaft on this particular motor is a special crankshaft because of the spacing, so Cresap had to balance the crank adding heavy metal in both ends of the crank in order to get it where they wanted it.

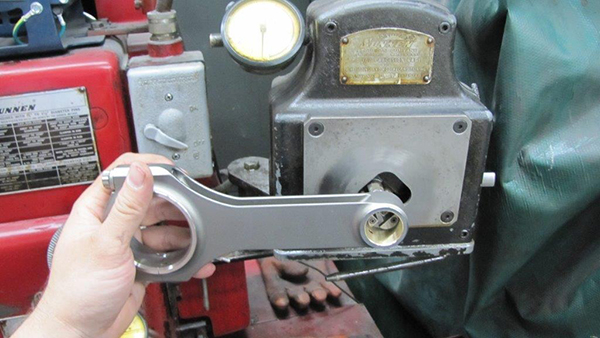

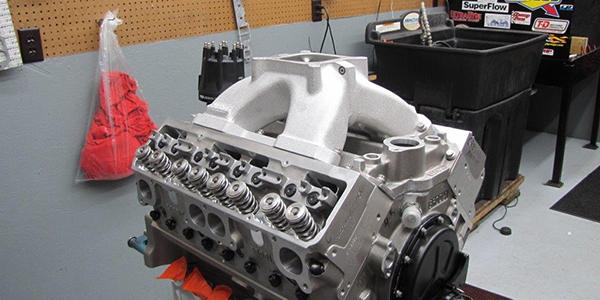

“The connecting rods are pretty much run-of-the-mill, small block rods,” he says. “The pistons are special to the 11-degree cylinder heads, and then the heads will be CNC’d and probably hand blended where necessary. We’ll also do a five or seven-angle valve job on the cylinder heads.”

The block for the 438 is a Brodix with 4.500˝ bore spacing. The crank is a billet Crower crankshaft. Connecting rods are Dyer Top rods. Pistons will be either Diamond or CP. The cylinder heads start life as Brodix and then they get CNC’d from there, and the intake manifold is a two-piece manifold and will be CNC’d to match. The engine has a billet 850 carburetor, titanium valves and titanium retainers and Crower stainless steel rocker arms – all particular to the 4.500˝ bore spacing. This engine will also get Cometic cylinder head gaskets and intake gaskets and the camshaft will be a COMP cam.

Depending on how the combination comes together, Yatchyshyn says this 438 SBC dirt super-late model engine should crank out 825-860 horsepower!

“Whenever you’re making over 800 horsepower in a dirt, super late, you don’t need another 10 horsepower because you’re probably only gonna hook 600 of it up at any given time anyway,” Yatchyshyn says. “So to put 15:1 compression ratio in a motor like this shortens the life of them so much. We usually try and stay around the 13.5:1 to 14:1 range. Usable rpms to 8,500 and those kinds of combinations will last 1,000-1,200 laps before they need freshening up – unless someone loses an air cleaner or the carburetor shaft goes bad and lets dirt in the motor.”

All said and done, Cresap’s repeat customer should be one happy racer on race days!

The Engine of the Week eNewsletter is sponsored by Cometic Gasket and Penn Grade Motor Oil.

If you have an engine you would like to highlight in this series, please email Engine Builder magazine’s managing editor, Greg Jones at [email protected].