PASS THE ROAST SLEEVES

We do quite a few re-bore and power hone jobs on small, single-cylinder engines in our shop. Usually, going to the next available oversize is all that is needed. However, when cylinders are badly damaged or have already been re-bored to the limit, we install an aftermarket sleeve to save the engine case.

When fitting the new sleeve we usually chill the sleeve in the freezer for a few hours while we are preheating the engine case. We have found that an electric roaster pan works really well for preheating these engine cases.

We set the temperature control to 375-degrees F and let the engine case soak for several hours. Next we simply and very carefully line up the ports and slip the sleeve into the case as quickly as possible. You can pick up an electric roaster pan for about $20-$25 at the local resale shop. If the resale shop doesn’t have one just leave a note and they will call you when one does become available.

I also use the electric roaster pan to preheat small parts like aluminum timing covers before I weld them. And it works well to dry out stick welding rod.

Jerry McLain

McLain’s Automotive Machine Shop

Cuba, MO

PHOTOS AREN’T JUST FOR SOCIAL MEDIA

A couple times a year a customer will tell me I forgot to give him back a sensor or bracket once an engine project is complete, so I have been taking photos of projects as customers drop them off. A picture from all sides will show any sensors, brackets, etc. that the customer didn’t remove. I can then go back to my camera or pictures downloaded to my computer and find out whether or not it came in with them.

I’m able to let the customer know whether they were here or not, and remind them that he was there when I took the pictures. If I really did forget to give them back at least I then know what to look for. I refer to the pictures if I have any questions upon reassembly as well.

I also take pictures of the finished product showing details of all the valve keepers being properly installed, oil gallery plugs, etc. I haven’t had any trouble with this yet, but you never know how competent the installer may be and this could save your rear end if someone else makes a mistake.

Dan Matton

D and D Auto Machine

Bloomington, MN

MARKED FOR REPEATABILITY

I always mark the flywheel when I’m done balancing so the customer will install it in the exact same spot as where I balanced it. I always shift it full right on the slop in the mounting bolts, opposite crankshaft rotation. Testing with a counterweighted flywheel shows the balance can change many grams when turned the other direction, depending on the bolt hole clearance.

Randy Torvinen

Torvinen’s Machine

Menahga, MN

PIN POINT PISTON MARKER

I took these broken-off valve stems and ground the tips to a point to mark valve centerlines on pistons for flycutting valve reliefs. Just install the head on the block and insert the stem in the guide point down and with the piston at TDC, give it a slight tap and you now have a reference point for machining

Rich Jones

Redline Automotive Competition Engines

Davie, FL

MORE ON PIPE PLUGS

I see a lot of pipe plugs today that don’t get removed or are all butchered up from guys struggling to get them out. Here’s my solution to avoid that scenario.

I use a torch to heat up the tapered pipe plug in the block until it glows red. Then I let it cool for a minute or so before I hit it with paraffin, beeswax or even a candle. The heat sucks the wax in and once it cools you can almost remove the plugs by hand.

Also, many plugs that come out of the big block Chevy today are drilled for an air bleed. Most aftermarket plugs are not. I drill them with a #52 drill bit (.060˝) to allow air to bleed out of those oil passages.

Lewis Andrews

Andrews Automotive

Savannah, MO

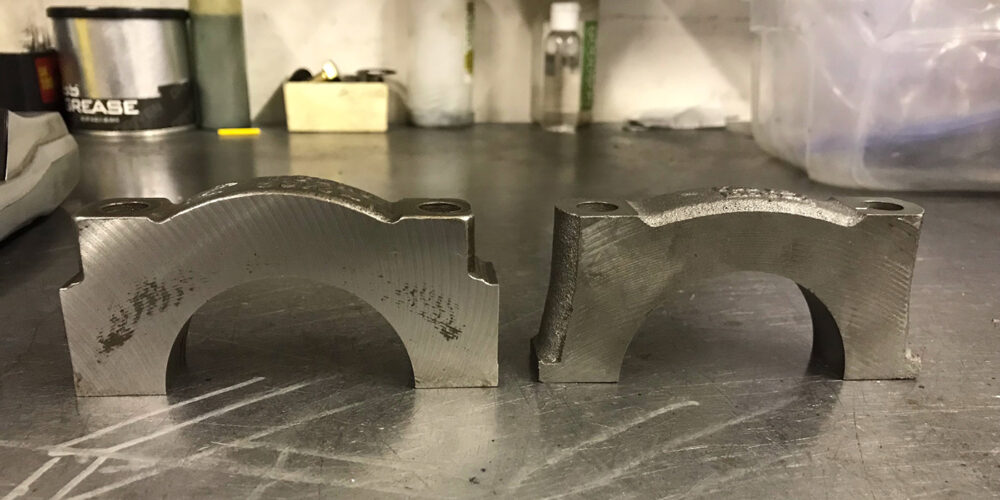

VALVE GUIDE SIZE GUIDES

I have an assortment of common valve guide sizes that are precision honed on the I.D. that I use for quickly setting up the valve guide dial bore gauge. It takes much less time than using the fixture and you can easily add or subtract from them to get the exact size for the job you’re doing.

Bonus tip: I have a billet block with different size lifter diameters as well. I set up the dial bore gauge for honing using that standard. Same procedure – over/under depending on the final size I need.

Ron Flood

Cedar Machine

North Branch, MN