December is certainly one our favorite times of the year. While everything is winding down our industry is fired up for the PRI Show in Indianapolis, and that means we get to gather with all you industry folks and spend a few days having great, face-to-face conversations. It was at the 2018 show that I got to spend a few minutes discussing business and engines with Carmen Trischitta of CT Performance Machine in Vineland, NJ.

Carmen, along with his father who owns J&C Auto and Speed Parts, have been in business since 1970. Carmen was just a kid way back then, but it was those early memories of running through the parts store aisles knocking things over and his dad hanging with Dan Jesel firing up big race engines that got Carmen hooked on a career in this industry.

Both Carmen and his father spent time on the race track, competing in Modifiend Eliminator, Pro Mod Bike, Pro Stock, Comp Eliminator and soon Outlaw Radial. Today, Carmen’s dad handles things in the parts store while Carmen handles the day-to-day at CT Performance Machine.

“I have the full machine shop for myself,” Trischitta says. “I’m machining and building everything and we do everything in-house. I’ll do a single cylinder up to a 12-cylinder engine. I have a lot of different stuff that I do. That keeps your wheels moving. You could take something from a V8 and use some of that technology in a four cylinder or vice versa. Everything pans out to horsepower, and if you do your job right things run right.”

CT Performance Machine will work on LS engines, big blocks, FEs, small block Fords, small block Chevys, Hyabusas, Suzukis, Hondas, 4G63s, and the list goes on. Whatever comes through the door, Carmen says he’ll tackle it and give it 120 percent.

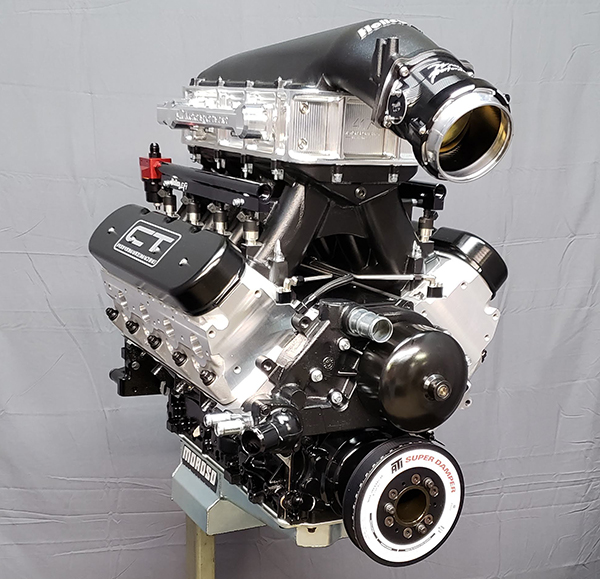

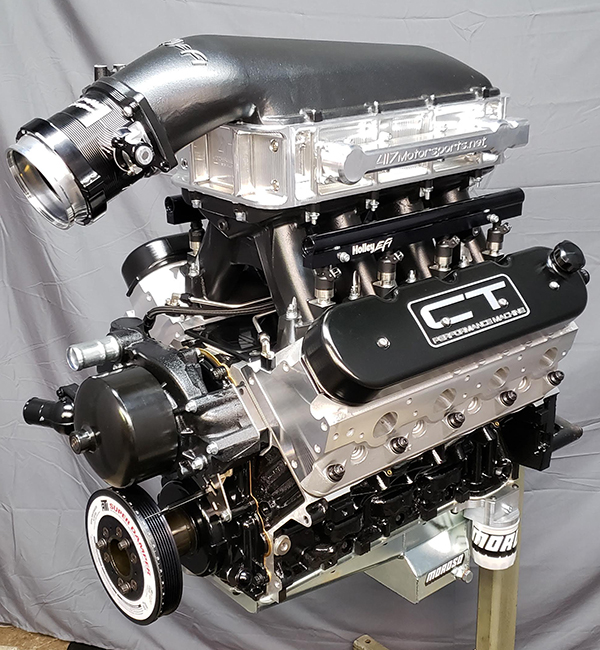

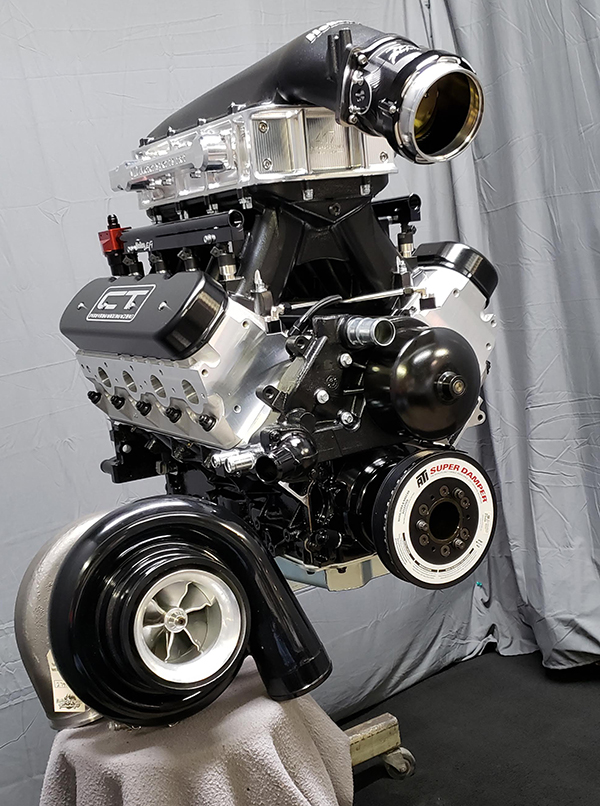

“We recently built a boosted LS3 Stroker,” he says. “It’s 416 cubic inches with an aluminum block.”

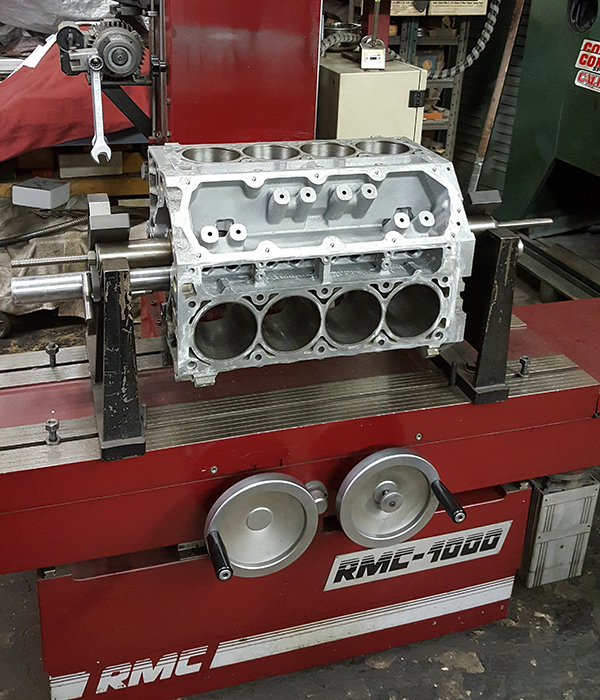

The block is stock from a Cadillac Escalade and came into CT in rough shape.

“I had to have a custom set of gaskets made from Cometic because I had to straighten the block out,” Trischitta says. “The dealership was in it trying to grind stuff away and put peaks and valleys all over it, which is bad news. I had to take .012˝ off the decks to get them where they needed to be so the gaskets would seal. Whatever I took off I had to add to the gasket, so Cometic helped with that.

“For the heads, I did a port job on the intake, exhaust and combustion chamber on a junk head that I had and sent it to a CNC guy to emulate, so that’s my proprietary head.”

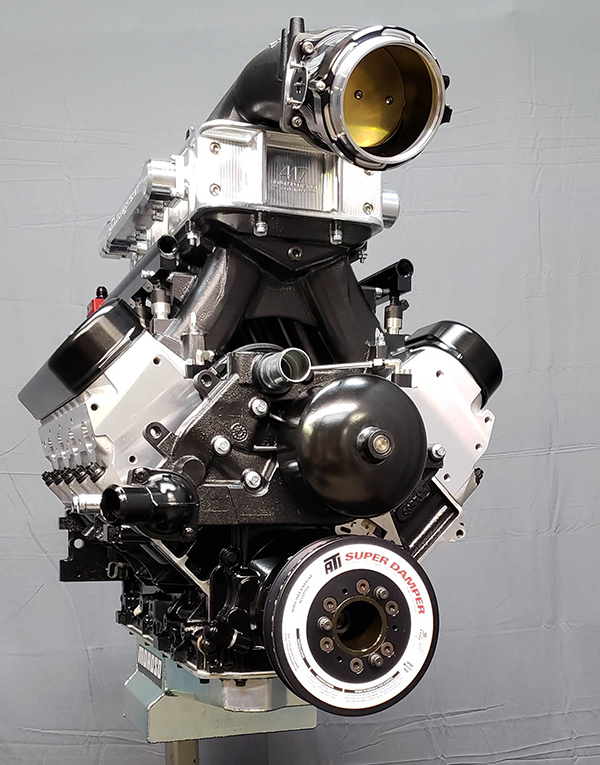

Other internal parts included a .4070˝ bore and stroke crank from Manley, as well as custom turbo rods and pistons from Manley, a Melling ported pump, Moroso pans, Ferrea valves, PAC springs, bushed and trued rockers, Trend pushrods, a Holley Hi-Ram manifold, a 417 intercooler, and a one-off billet throttle body from KCS Advanced Machining Services.

“Shaun’s Custom Alloys in Australia made me some valve covers that say CT Performance,” he says. “The engine also has a custom ground turbo cam from Bullet, Morel billet HLT (hydraulic limited travel) lifters, a Cloyes billet timing chain, and King coated XP race bearings.”

To top off this LS3 build, Trischitta used a 94mm Bullseye turbo. Overall, the build went smoothly, and according to Trischitta, the only roadblocks were having to wait for some custom, one-off pieces to be made, which were worth the wait.

“I hate being cookie cutter,” he says. “I like having stuff no one else has like that throttle body. Sometimes you’ve got to have patience for that stuff, because it doesn’t happen overnight.”

The LS3 engine is going in an ’80 Chevy C10 with full Holley EFI. With 1,100-1,200 hp on tap, Trischitta and his customer are going to see how well it runs.

“One thing is for sure – we’re going to see what that stock block holds,” he says. “We’re going to push it for sure. That’s what I built it for – not to play around with it.”

It’s conversations like these that make our industry a fun one, and it doesn’t hurt when the engine builder is a fan of ours too.

“I get the magazine every month,” Trischitta says. “I read it all the time – in print, online, on Instagram. When my dad told me Engine Builder magazine had called, it made me feel really good. It made me feel proud that someone sees my good work.”

This 416 cid turbocharged LS3 Stroker is certainly some good work!

The Engine of the Week eNewsletter is sponsored by PennGrade Motor Oil.

If you have an engine you would like to highlight in this series, please email Engine Builder magazine’s managing editor, Greg Jones at [email protected].