It’s been almost 20 years since the first of many The Fast and the Furious films entered the public eye leading to a renaissance for the sport compact car and engine market, and it’s been almost as long since two friends – Luke Wilson and Josh Klein – started 4 Piston Cylinder Heads in Danville, IN as a way to fund their racing habit. The business quickly took off and it wasn’t long before the shop, which focuses on cylinder head development, turned into much more than just a way to go race.

“Josh and I started this company more or less as kids,” says Luke Wilson, owner of 4 Piston Cylinder Heads. “At the time, Josh and I were porting heads by hand and quickly realized that we weren’t going be able to make any money doing that and we were going to wear ourselves out before we got to any reasonable age doing it. That’s when we decided we wanted to put out a higher quality product.”

Wilson noticed the market was flooded with low-end products, but realized there were customers out there who want a higher-end, boutique product. The duo soon changed their business mentality and their cylinder head products to reflect the higher end market, and the business grew.

“We just grew and grew and kept putting out a good product and got into more engine development, and over time, that snowballed,” Wilson says. “In the past two years, we’ve been filling a void. Our initial idea behind the whole business was to just do cylinder heads and supply them to the end user and supply them to the engine builder. As that evolved, we started building more engines because there’s a big need. There’s not a lot of high-quality, sport compact engine builders.”

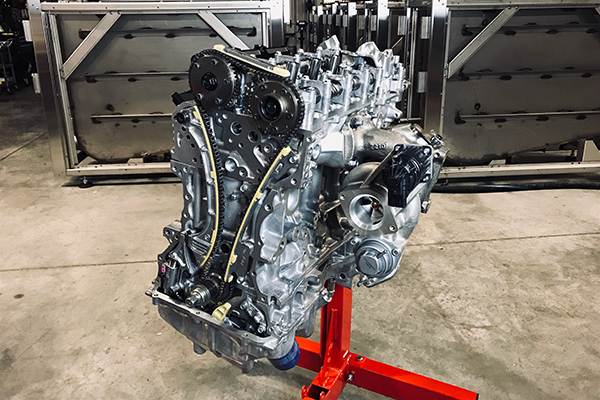

The growth of the market is directly reflected in 4 Piston Cylinder Heads’ growth as well. The 7-employee shop, which opened in 2000, focuses on cylinder head development and sport compact engine building with a heavy emphasis on Honda, but will also build Mitsubishi Evos, Nissan GT-Rs and some Ford EcoBoosts. The shop, which started in a garage, is now planning to add 12,000 sq.-ft. to it’s current building.

“The draw to sport compact is the availability of the cars and engines all over the globe,” Wilson says. “Most people don’t have the budget to buy a performance car and then dump another small fortune into modifying it for racing. A lot of people are buying entry-level, four-cylinder cars and then putting money into making those vehicles race cars.”

The first year 4 Piston started building engines, the shop completed about 30 builds. Last year, the shop did 160 engines, and this year, Wilson estimates they’ll do 200.

“We’re booked out through June right now,” he says. “The engine building side has become more of our business because there’s a void in the market. There’s a lot of guys shooting for the low end and there’s not a lot of guys shooting for the higher end customer who wants a motorsports-grade engine. That’s where we’re filling in.”

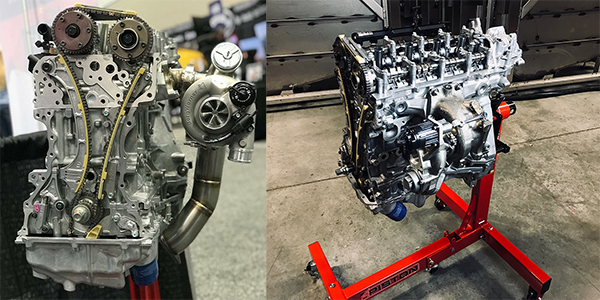

While 4 Piston Cylinder Heads does a lot of work on Honda K-series engines, the shop recently started putting resources into further developing Honda’s new Civic Type R K20C1 engine, and according to Wilson, there’s real potential behind this powerplant.

“We bought two of the Civic Type R cars to do work on the engines,” he says. “Not many people have seen that engine taken apart, let alone built into something substantial.”

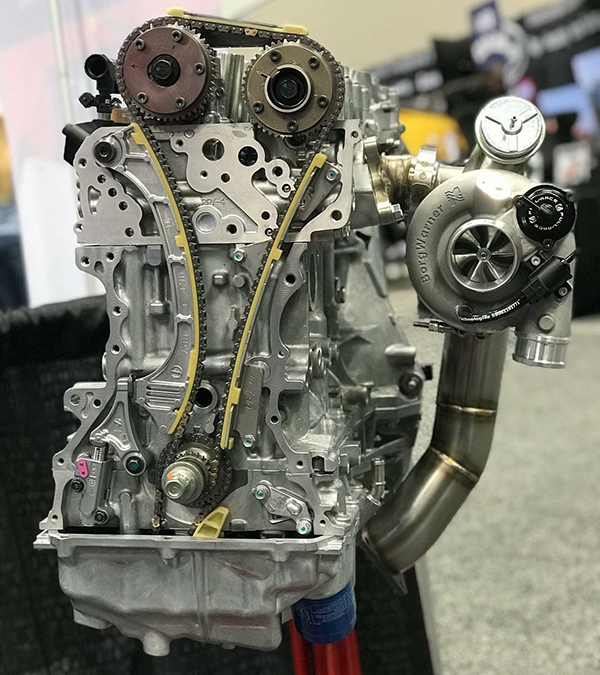

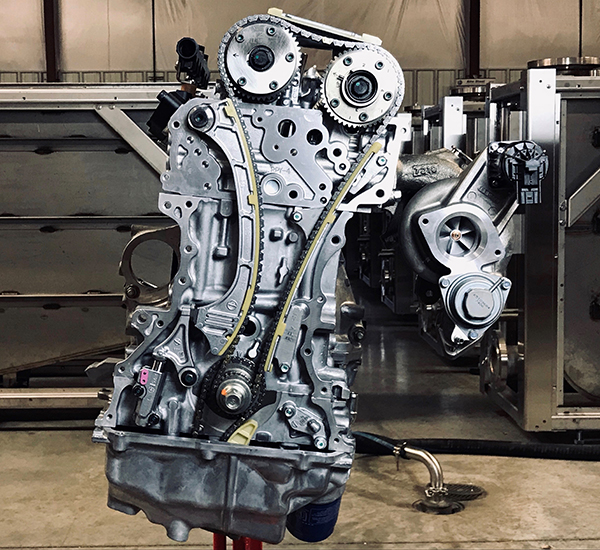

While the familiar “K” of Honda’s engines remains in this new engine’s name, these engines are not merely an evolution, but rather a completely new design.

“They’re pretty big engines from the factory – we’re bending rods at 400 horsepower, which is unlike Hondas in the past,” he says. “It’s neat and it’s new and no ones seen the stuff. This engine is a totally different approach. It’s a direct injection, turbo engine. It’s the Honda that we’re going to be working with for the next 20 years. That’s the reality.”

The K20C1 is a direct injected, turbocharged, 2.0L engine that produces 306 hp and 295 lb.-ft. of torque from the factory. This engine is not only being utilized in on-road Honda Civics, but also purpose-built racecars, including F4 and F3 feeder series for the climb to Indy Car, British Touring car, IMSA, and many other forms of endurance racing.

“What we are doing is making the engines stronger, and setting them up for higher output,” Wilson says. “The stock turbo can produce 400 lb.-ft. of torque at low rpm and over 400 hp.”

While the Civic Type R has some pretty cool technology in it, there are not a lot of people who know the ins and outs of the K20C1 engine because they’re brand new and people aren’t taking them apart yet. However, people are breaking connecting rods, so shops like 4 Piston Cylinder Heads have a line of engines to build.

Two of the differences between the Civic Type R engine and Honda engines of the past are direct injection and a tumble port design in the cylinder head. This is where Wilson and 4 Piston Cylinder Heads specialize.

“Honda’s of the past 20 years have flown 300 cfm,” he says. “This thing flows 150-160 cfm, but it’s a tumble port design, so it’s got a big sharp point right before the valve – like the EcoBoost – to create tumble so they can get this efficient fuel burn in the chamber. However, that really kills flow. One thing Honda did differently is they gave this a big ass race port where the EcoBoost and some of these other engines are tiny, little ports going into a little sheer before the valve to tumble the air.

“For the cylinder head, we remove some of the tumble port design for fuel economy and to increase airflow by 140 cfm without drastically increasing the port volume. This brings the power in a couple hundred rpm sooner, and allows for around 20 hp in gains on the stock turbo, but at lower boost pressure.

“We also relieve some of the back pressure with our exhaust port, which becomes important when upgrading to larger turbos that will exceed 600 hp. Exhaust Gas Temperature (EGT) can be pretty high in these the way they are being used in endurance racing, and that is something that we have to help teams to control to get the engines to last. We replace the valves with Ferrea Competition Plus Super Alloy valves to handle the extra exhaust heat, and use a higher pressure Pac spring and titanium retainer for rpm use over the factory head…which runs out of steam before 7,000 rpm.”

According to Wilson, the market interested in these engines is going to be really, really excited about 400 horsepower, but his team isn’t stopping there!

“We took the stock car and put a MoTec ECU on it and we turned it up,” he says. “It was easy to add 120 horsepower without touching any part of the car, other than putting a computer in it and about 30 percent ethanol in it. It’ll also deliver well over 400 ft.-lbs. of torque. It’s pretty wild for a little engine, but they’re different.”

The K20C1 engine also has an offset crank in relation to the bore so that the piston is straight up and down when it’s on a power stroke. For this build 4 Piston decided to use JE pistons and Saenz connecting rods, which are out of Argentina.

“We replace a rather fragile OEM connecting rod with our Saenz I-beam rod that is rated at over 800 hp,” Wilson says. “It is also more than 100 grams lighter than the OEM rod. The pistons are replaced by JE forged pistons, which that have a thicker top, thicker pin boss area and a tool steel wrist pin. We offer replacing the OEM sleeve with a ductile iron sleeve for larger bore size, and use an o-ring for additional cylinder sealing. We’re designing the engine to be able to handle about 800 horsepower.”

Due to the capabilities this new engine offers, Honda has been pushing the K20C1 for all kinds of racing applications, and 4 Piston Cylinder Heads is positioned at the forefront for building the powerplant well beyond OEM specs.

“These new turbocharged, direct injected engines can make 800-1,000 hp – piece of cake,” Wilson says.

The Engine of the Week eNewsletter is sponsored by PennGrade Motor Oil.

If you have an engine you would like to highlight in this series, please email Engine Builder magazine’s managing editor, Greg Jones at [email protected].