When choosing a name for his shop, Marlon Goldberg wanted to be discrete. He chose Workshop 5001 to disguise exactly what his shop specialized in. Passersby would wonder was it a wood working shop? Was it a metal shop? They would only know that there was work being done, but not know what kind. The truth – Workshop 5001 is a premier automotive restoration shop with a heavy focus on Porsche. The 5001 is an ode to the street the shop is located on in the Los Angeles area.

“Five years ago, I bought this building and restored it,” Goldberg says. “It’s a cool, mid-century modern warehouse that we restored the same way that we would restore cars, and it looks great.

The name of the business came about because our address is 5001 Exposition Boulevard. It’s actually the Northern-most part of South Central LA. It’s becoming a hip neighborhood, but when I bought the building five years ago, it was still a bit of a war zone and we didn’t want anyone to know what we were doing in the building. All the windows are an obscure glass so you can’t see in, but you still get light. To the outside it looks like this abandoned building with a lot of cameras around it and no one knows what we do here, but when you come inside it’s a different world.”

The world Goldberg has created is one of Porsche wet dreams. Workshop 5001’s builds are completed as bare tub restorations, including Mil-Spec wiring, full interiors, motorsport suspension, custom components, and top-notch engine work. Growing up, Goldberg was infatuated with Porsche and he credits his dad for fueling his passion.

“I was always fixated on Porsche stuff because I grew up with it,” he says. My dad is a doctor, and while he’s not in the automotive industry, he always drove Porsches. That’s what sparked my interest initially.”

From there, Marlon had apprenticeships in high school, and when he was in college at The New School in New York he interned at Manhattan Motorcars, a Porsche dealer in New York City.

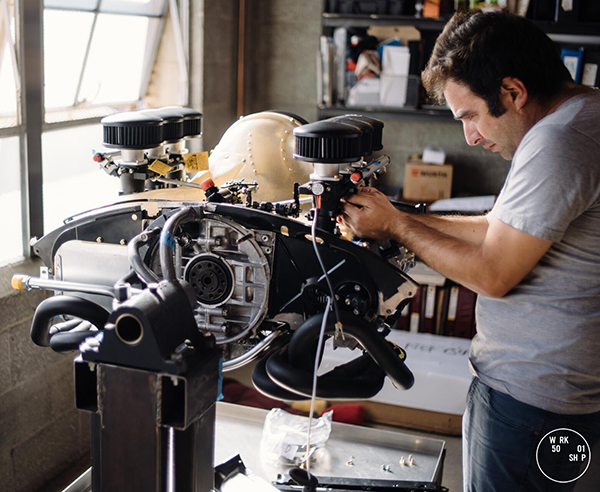

“Their shop foreman was this guy Bobby who I became friendly with,” he says. “He used to stay late and build motors at night. That’s where I first got exposed to building the air-cooled Porsche motors. I knew immediately that was what I really wanted to do.

“I love air-cooled Porsches. There are other cars I like, but I can say with a lot of confidence that old 911s are probably the best car ever built. There’s just something really unique, special and capable about them. These cars are infinitely serviceable and restorable. We can resurrect them no matter how bad they are through our restoration process. Beyond that, it’s just this unexplainable fascination with 911s specifically. They just make sense and the engines are a further extension of that. I think the air-cooled flat six Porsche motor is one of the best engines and it’s a key element to making a 911 the great car that it is.”

Throughout his career, Goldberg has worked for Porsche dealerships, as a Ferrari pit crew member and at Singer Vehicle Design – a Porsche restoration company. However, he really got motivated to do his own thing when he met Dieter Inzenhofer, one of three partners who founded Andial, which was effectively Porsche Motorsport North America for a time.

“When I came to California, I wanted to work at Andial,” Goldberg says. “They were well known for their Porsche engines. I had actually interviewed with them during college and they were going to hire me, but they were about to retire and Porsche Motorsport was taking over the whole building. That opportunity fizzled, but I remained in contact with Dieter – he was the main engine builder and head mechanic.

“One day I went to Dieter and told him that my dad’s ’91 911 engine needed to be rebuilt. I asked if I could spend some time redoing that motor with him and he agreed to it. I was basically the only person who was a non-employee whoever trained there. I got these varied experiences learning from a few guys who really knew the motors inside and out. That’s what got me going on it.”

Those experiences and desire to build great Porsche cars and engines led Goldberg to opening Workshop 5001 five years ago. The shop is 3,500 sq.-ft. and has six full-time employees. Many of the full hot rods built at the shop start at $500,000, and some are more than a million!

“Everything in our cars is next level crazy – the motors are the same thing,” he says. “We’re typically quoting 12 to 18 months for a full restoration on a 911.”

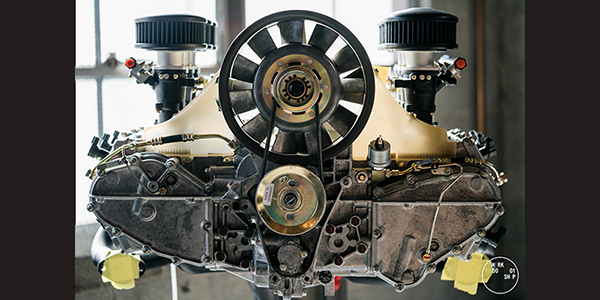

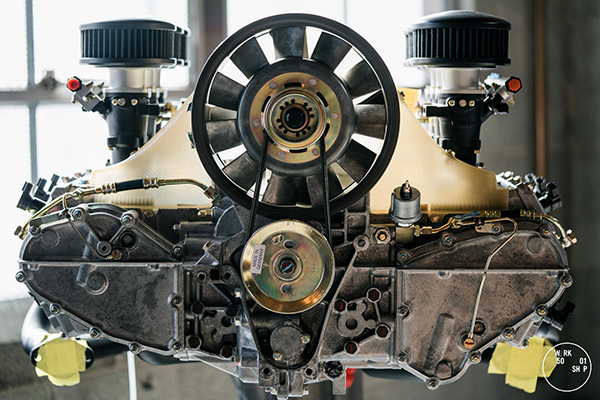

Marlon and the folks at Workshop 5001 recently finished up the restoration of a 1972 911 Porsche with an air-cooled, flat six, twin plug 3.4L engine that was displayed at Luftgekühlt, an air-cooled Porsche show. The client is someone Marlon has worked with before on several car projects.

“The client really appreciates our attention to detail,” he says. “We’re really lucky to have these clients who allow us to build such extravagant hot rods that are in this realm somewhere between art and car or functional artwork.”

Porsche fanatics will all tell you the ‘72 911 is considered the holy grail because it’s the one year with the oil door, among other reasons.

“They had to do away with the oil door because people were putting gas in the oil tank by accident back in the ‘70s,” he says. “The car has the oil tank in front of the rear axle so from a weight distribution standpoint, it was superior to every other 911 built up until ‘89.”

Workshop 5001 decided this build would use mixed and matched parts from different eras of 911s to create a ‘what if’ car.

“Because of the huge interchangeability with Porsche cars, you can take almost any air-cooled Porsche motor from any year and stick it in any other year chassis from 1965 to 1998,” Goldberg says. “This particular engine I got from a 1986 911 that was 3.2L. For me it’s all about the motor in the car. The chassis is obviously done to the highest level, but it’s the house for this badass motor.”

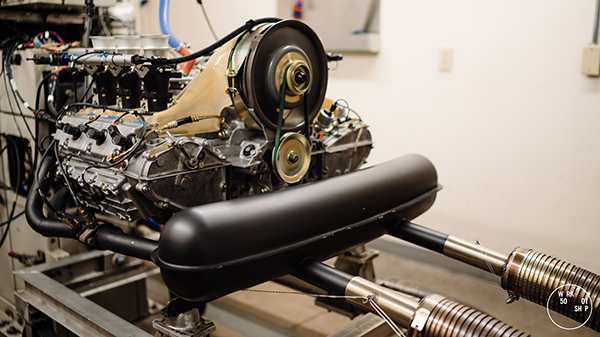

Engine assembly and some machine work is done by Goldberg at Workshop 5001, while head work and dyno sessions are done at Randy Aase’s shop, Aasco Performance, Inc.

“Randy and his brother are big names in the Porsche world and he’s also been a great mentor to me,” he says. “When you run into problems, he’s someone who I can talk to and run things by.”

Goldberg also works closely with well over 100 vendors who are intimately involved in each build to make them all come together, especially in a short period of time. On this 911 engine, Goldberg used titanium connecting rods, rockers and a straight cut intermediate gear all from Pauter. The engine also has CP pistons, Mahle Motorsport cylinders, Dema Elgin cams, Kinsler injection, and a MoTec M130 ECU and a MoTec PDM30. The rest of the parts in the engine are Porsche.

“It’s the first engine that we built with Kinsler injection,” Goldberg says. “When you want to improve a German engine, you’ve got to look at what some of these guys have done with American engines. That’s where a company like Kinsler comes into play. They’re dealing with flow and changing the taper of the intake and port matching and working with harmonic issues – they’re thinking about stuff on a different level than anyone who’s typically doing Porsche motors. That’s been a great relationship that I think is really taking our motors to the next level.”

Workshop 5001 has also been working closely with Elring to seal their Porsche engines.

“There are some gaskets in this engine from Elring, and the conversation has just gotten started with Elring about developing a gasket kit with them,” he says. “They make most of these gaskets individually, but there’s really a need within the world of gasket kits for something that’s a premium product. As an engine builder, if you get a bad, dried out gasket or o-ring or it’s something you miss in assembly, especially with a Porsche motor, it can be a 40-50 hour mistake because this motor sort of stacks on itself. If something is leaking in the bottom end of the motor, you’ve got to take the whole thing back apart. So I wanted to develop something with Elring that helps us and potentially helps other engine builders.”

With the engine all sealed up and the restoration of this ’72 911 Porsche complete, the client will be enjoying 318 horsepower under the hood compared to a factory 208 horsepower. German engineering restored to its finest!

The Engine of the Week eNewsletter is sponsored by PennGrade Motor Oil and Elring – Das Original.

If you have an engine you would like to highlight in this series, please email Engine Builder magazine’s managing editor, Greg Jones at [email protected].