HOMEMADE HEAD BENCH

I fabricated an easy to clean steel-topped cylinder head bench. Wrapping over the edge allowed for drilling holes, then inserting adjustable pipe holders. I can easily position any passenger car or light truck head for various work performed, from grinding seats to valve spring installation.

Gary Muller | Gary’s Custom Engines & Cylinder Heads | Sterling, AK

CAM BEARING INSTALLATION

There’s nothing worse than having to fit a camshaft after installing new cam bearings, because they are too tight. I dial-bore gauge check all cam bores of the “known offenders.” I also use a Sunnen Jr. hone to hone cam bores to the correct size before I ever install the bearings. Since starting this process, I have not had to use a “reamer camshaft” to fit bearings. They can leave bearings looking terrible. I charge for the time to dial-bore check and the time to hone or repair the block.

Lewis Andrews | Andrews Automotive | Savannah, MO

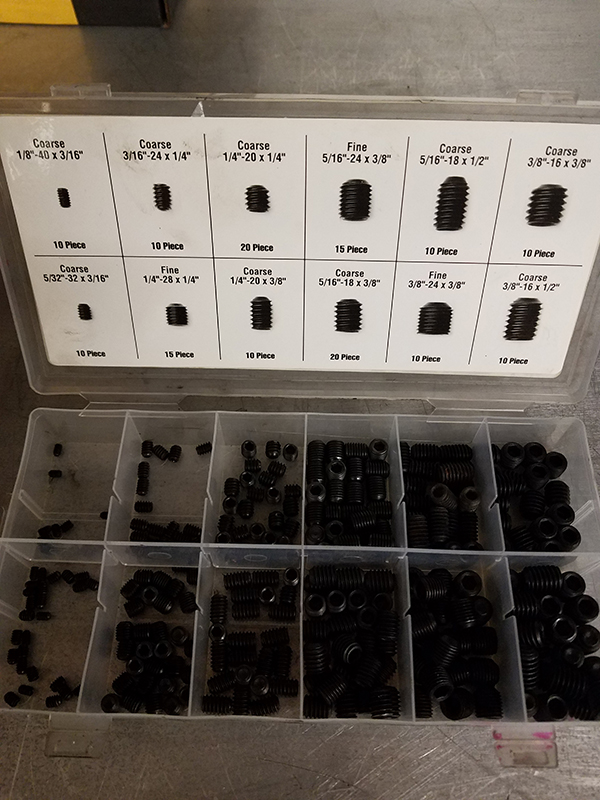

SET IT AND FORGET IT

Inexpensive set screw sets are very handy to have around the shop. They work great as oil restrictors. They can also be used as oil galley plugs in small import and late-model cylinder heads if you need to remove steel oil galley balls for cleaning. These are a cheap set that drill like butter. On an engine like a BB Chrysler or an FE Ford, I like to tap and restrict the oil galley in the top of the cylinder head just under the rocker shaft. That way, if an orifice change is desired, its easy to remove the set screw and change the restrictor size.

Jake Sampson | Sampson Race Engines | Inver Grove Heights, MN

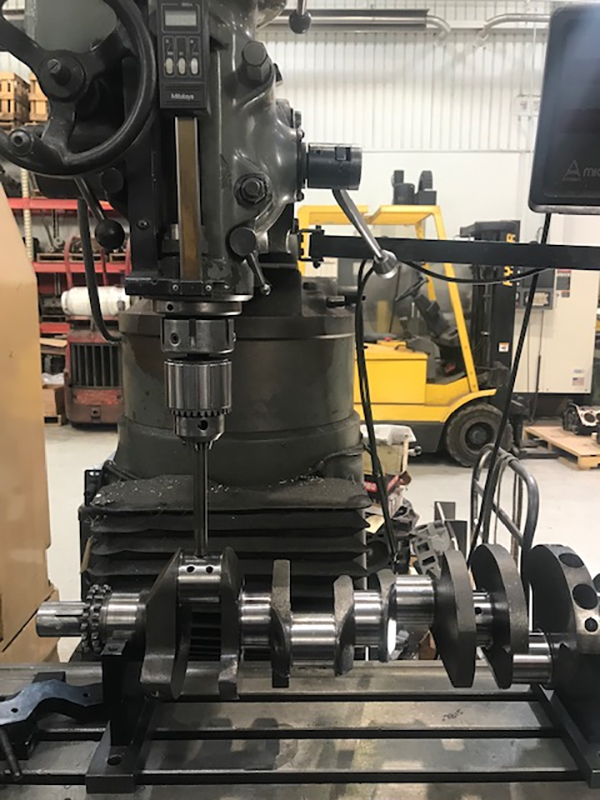

CRANK STROKE CHECK

I have a quick and easy way to check or measure the stroke of a crankshaft. I put the crank on some V-blocks on the vertical mill table. I chuck up a BB Chevy fuel pump pushrod or any similar round stock in a drill chuck. Position the rod throw pointing up and come down onto the journal with the round stock. Zero your Digital Read Out (DRO) for Z. Rotate the crankshaft 180-degrees and come down onto the journal again. The reading on your DRO will be the stroke of your crankshaft for that journal!

Nick Jones | Automotive Machine | Fraser, MI

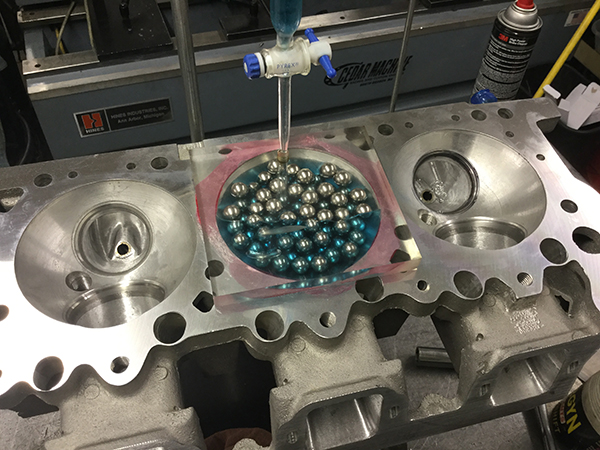

ITS ALL BALL BEARINGS THESE DAYS

When checking volume on large chambers or ports, I fill them with precision steel ball bearings. It requires less time to fill and less fluid. Simply calculate the volume of the ball you’re using and multiply by the number added. Add that to the reading from your burette and you have the volume. Be sure to dry the bearings on a towel between tests. On many 100cc or larger chambers like Hemi and BBC, you only have to fill the burette once. It really speeds up the process on smaller chambers too. On large intake ports, you can use precision 1˝ x 1˝ blocks of aluminum in addition to bearings.

Ron Flood | Cedar Machine | North Branch, MN

FUEL LINE CRACKS

When rebuilding large diesel engines like Caterpillars with high-pressure fuel lines running along the blocks or heads, make sure to install all of the factory line clamps and hold downs back in the factory location. They are designed to hold these lines from moving and flexing, which will cause them to crack and leak fuel over time, if not secured correctly.

Ken Marlar | Sterling Engine Parts | Minneapolis