As a teenager, Jay Dickens was very interested in race cars and engines. It didn’t hurt that his high school automotive mechanics teacher was one of the best race engine builders in the country, and built engines for Bobby Allison and several other big-name racers of the time. Unfortunately, Dickens’ teacher, Bobby Brown, was killed in a plane crash in 1987, but the things Jay learned from his teacher live on at his engine shop, Jay Dickens Racing Engines, located in Aberdeen, MS.

“I graduated school in 1982 and that was his last year teaching,” Dickens says. “I just showed interest at a young age and went to work in his shop where I learned everything – one thing at a time. Eventually, I got to where I could start my own deal.”

Jay opened Jay Dickens Racing Engines in 1994 and has been at it ever since. The engine machine shop specializes in circle track engines.

“We do mostly late-model dirt, but I’ve done a lot of pavement,” he says. “I’ve done some short track and some NASCAR stuff as well. But primarily our focus today and the last several years has been circle track dirt. We primarily build Chevys and Fords.”

Jay Dickens Racing Engines (JDRE) is 5,500 sq.-ft. and has five full-time employees.

“We do everything but crank grinding here,” he says. “We have all the necessary equipment to do our job and do it well. We’re pretty fortunate and pretty successful at what we do. We supply engines for people all over the country as well as Australia and Canada. We supply engines for about 75 race teams.”

Jay says the shop has been building a lot of wide bore engines in the past, but recently has been working on a number of standard 4.400˝ bore space small block Chevy engines.

“Those run better than anything I’ve ever seen,” Dickens says. “We can’t build them fast enough and all the parts in our engines are custom made.”

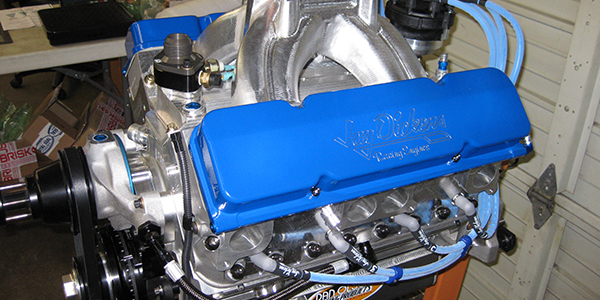

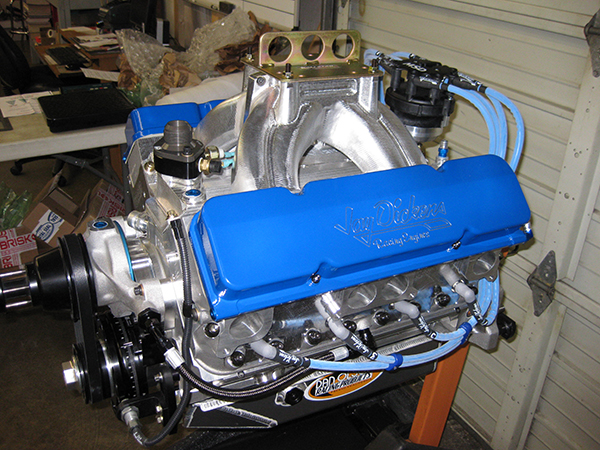

This particular engine is a 432 cid small block Chevy with 11-degree cylinder heads. JDRE starts the build using Brodix blocks and cylinder heads.

“The block comes to us 75% machined,” he says. “We have to do the final deck heights. We have to bore and hone the cylinders and do the cam tunnel, the lifter bores, and the main bearing bores. We have to machine all of the moving parts that go into the block.”

The engine’s crankshaft comes to JDRE from Callies and gets balanced in-house. For the rotating assembly, JDRE uses Dyers rods, Diamond pistons and Total Seal piston rings. From there, the work moves on to the short block.

“The Brodix cylinder heads get CNC’d and then we finish them and do the final cc on the chambers,” Dickens says. “With the technology now in CNC equipment, even our intake manifolds now are split in two halves and they’re CNC’d. It takes a lot of man hours out of the equation.”

For the valvetrain, JDRE uses custom valves from Xceldyne, a custom spring combination from PSI and T&D Machine stainless steel rocker arms.

In addition, the 432 cid SBC gets a camshaft from COMP Cams, a custom, billet aluminum manifold that JDRE makes in-house, ACL bearings, a Dan Olson oil pan, billet valve covers from Ultra Pro Machine, and an MSD distributor and crank trigger system.

“For this engine, the compression ratio is 14.8:1,” Dickens says. “These engines are pushing right around 690-700 ft.-lbs. of torque and crank out about 875 horse.”

Engine of the Week is sponsored by PennGrade Motor Oil and Elring – Das Original.

If you have an engine you would like to highlight in this series, please email Engine Builder magazine’s managing editor, Greg Jones at [email protected].